A kind of high temperature resistant defoamer and preparation method thereof

A defoamer and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant defoamer and its preparation, can solve the problems of easy oil drift, poor stability, and easy precipitation, etc., achieve enhanced encapsulation, solve poor high-temperature stability, and operating conditions less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A kind of preparation method of high temperature resistant defoamer, polysiloxane silicone grease, ethoxylated acetylenic alcohol emulsifier, dispersant, thickener and water are put into the emulsification pot of formula quantity, mechanical emulsification, setting stirring speed is 800-1200r / min, stirring for 0.5-1h to obtain a high temperature resistant defoamer.

[0038] The preparation method of the high-temperature-resistant defoamer provided by the embodiment of the present invention has fewer steps, simple process, low requirements on operating conditions, and high production efficiency.

Embodiment 1

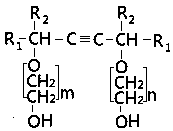

[0041] A high temperature resistant defoamer, prepared according to the following steps: 10% ethoxylated acetylenic alcohol emulsifier, 19.2% polysiloxane silicone grease, 0.8% dispersant, 2% thickener and the rest of water Put it into an emulsification pot, set the stirring speed to 1200r / min, and mechanically emulsify for 1 hour to obtain a high temperature resistant polyether modified silicone defoamer. Wherein, the models or molecular structural formulas of the above-mentioned components are shown in Table 1.

Embodiment 2

[0043] A high temperature resistant defoamer, prepared according to the following steps: 8% ethoxylated acetylenic alcohol emulsifier, 25% polysiloxane silicone grease, 1% dispersant, 3% thickener and the rest of water Put it into an emulsification pot, set the stirring speed to 800r / min, and mechanically emulsify for 1 hour to obtain a high temperature resistant polyether modified silicone defoamer. Wherein, the models or molecular structural formulas of the above-mentioned components are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com