Electrode material preparation method

A technology of electrode materials and nanomaterials, which is applied in the field of preparation of electrode materials, can solve the problems of low conductivity and specific surface area, uneven pore size distribution, and complicated preparation process of carbon materials used in electrodes, so as to improve electrochemical performance and improve the preparation process. Simple, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention provides a kind of preparation method of electrode material, and this method comprises:

[0018] The solution containing magnesium ions is mixed with the solution containing hydroxide ions, filtered and separated to obtain nano-magnesium hydroxide materials;

[0019] Disperse the nanomaterials in N,N-dimethylformamide to obtain a dispersion, then add polyacrylonitrile and heat at 50-80°C for 1-4 hours to obtain a mixed mucus, and the amount of polyacrylonitrile in the obtained mixed mucus The mass fraction is 5-15%;

[0020] Electrospinning the mixed mucus, and heat-treating the obtained raw silk in air atmosphere at 250-300°C for 0.5-2 hours;

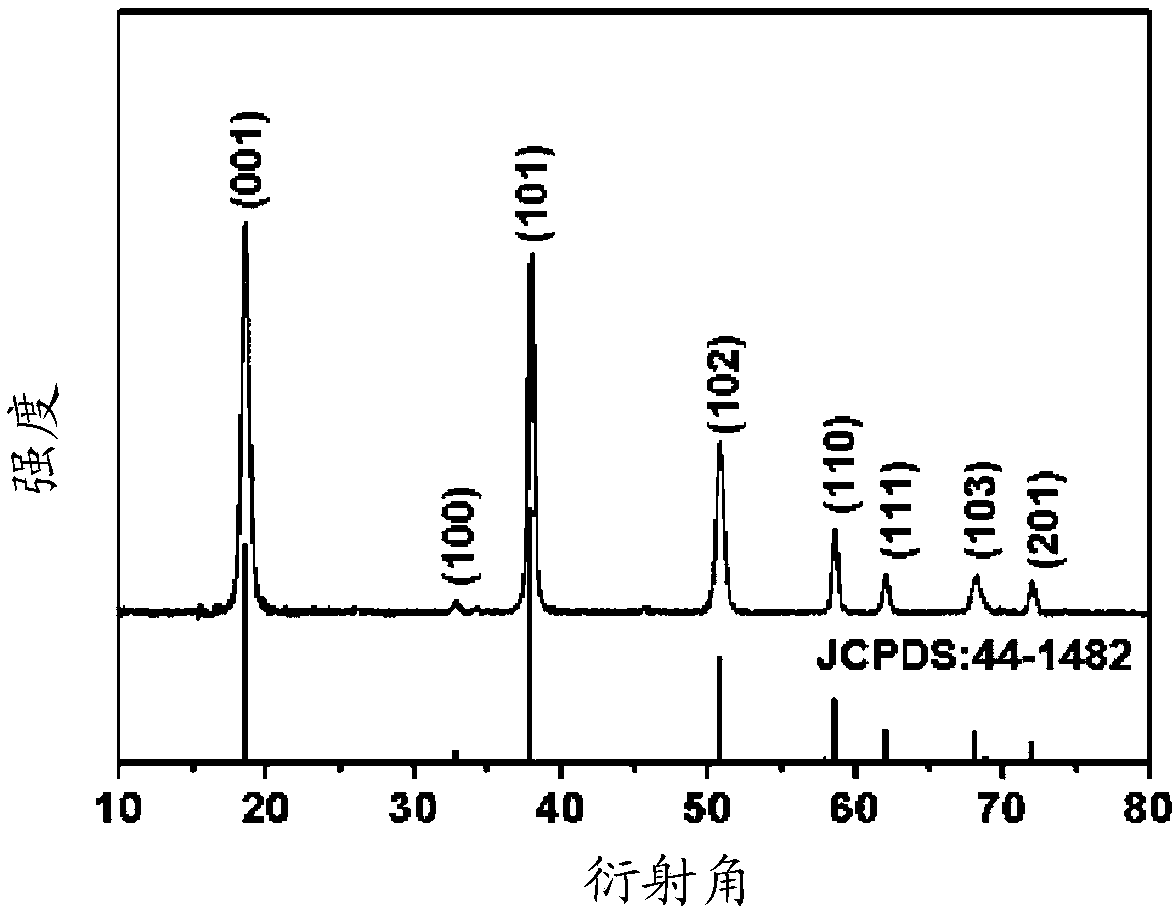

[0021] Heating the heat-treated raw silk in a nitrogen atmosphere at 800-1000°C for 3-5 hours, cleaning and drying to obtain an electrode of an in-situ nitrogen-doped carbon fiber / magnesia composite material; making the obtained composite material into an acid treatment to obtain the in-situ nitrogen-dope...

Embodiment 1

[0035] 1. Dissolving magnesium nitrate hexahydrate and sodium hydroxide in deionized water respectively to obtain magnesium nitrate solution and sodium hydroxide solution;

[0036] 2. While stirring, slowly add sodium hydroxide solution dropwise to magnesium nitrate solution for reaction, heat the obtained turbid solution in a water bath to 100°C, stir, reflux for 3 hours, cool to room temperature, and then perform centrifugation to obtain nano-hydrogen Magnesium oxide material;

[0037] 3. Disperse the obtained 10g nano-magnesium hydroxide material in 90g N,N-dimethylformamide to obtain a dispersion liquid, add 35g polyacrylonitrile to the dispersion liquid, and heat at 70°C for 3 hours to obtain a mixed mucus ;

[0038] 4. Electrospinning the mixed mucus at a temperature of 25°C, a voltage of 12 kV, and a humidity of 40%, and heat-treating the obtained raw silk in an air atmosphere at 280°C for 1 hour;

[0039] 5. Heat the raw silk after heat treatment in a nitrogen atmosp...

Embodiment 2

[0041]1. Disperse 10g of nano-magnesium hydroxide powder in 90g of N,N-dimethylformamide to obtain a dispersion, add 35g of polyacrylonitrile to the dispersion, and heat at 70°C for 3 hours to obtain a mixed mucus;

[0042] 2. Electrospinning the mixed mucus at a temperature of 25°C, a voltage of 12 kV, and a humidity of 40%, and heat-treating the obtained raw silk in an air atmosphere at 280°C for 1 hour;

[0043] 3. Heat the raw silk after heat treatment in a nitrogen atmosphere at 900°C for 4 hours, soak the heated material in hydrochloric acid, wash it with deionized water, and dry the cleaned material at 60°C to obtain the raw silk Nitrogen-doped porous carbon fiber electrode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com