Flexible circuit board cleaning agent, flexible circuit board cleaning process, flexible circuit board and electronic equipment

A flexible circuit board and cleaning agent technology, which is applied in the direction of surface active detergent composition, detergent composition, detergent compounding agent, etc., can solve the problem of unsafe and environmentally friendly cleaning agent, unclean cleaning of rosin, and white spots on circuit boards and other problems, to achieve good decontamination cleaning effect, convenient batching, and reduce corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

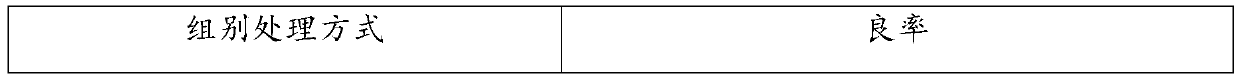

Examples

Embodiment 1

[0128] A flexible circuit board cleaning agent is composed of the following components in mass percentage: 30% of N-methylpyrrolidone, 35% of butyrolactone, 1.5% of glycolic acid, 2% of penetrant JFC and 31.5% of water.

Embodiment 2

[0130] A cleaning agent for a flexible circuit board is composed of the following components in mass percentage: 45% of N-methylpyrrolidone, 20% of butyrolactone, 3% of glycolic acid, 0.5% of penetrant JFC and 31.5% of water.

Embodiment 3

[0132] A cleaning agent for a flexible circuit board is composed of the following components in mass percentage: 37% of N-methylpyrrolidone, 28% of butyrolactone, 2% of glycolic acid, 1% of penetrant JFC and 32% of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com