Water-based elastic paint with high drying speed and long activating period and preparation method thereof

A pot life, elastic paint technology, applied in the field of coatings, can solve the problems of slow drying speed, short open time, limiting the application range of water-based elastic paint, etc., to achieve the effect of easy spraying, fast solvent release, and improved scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A water-based elastic paint with fast drying and super long pot life is composed of component A resin paint and component B curing agent in a weight ratio of 2:1;

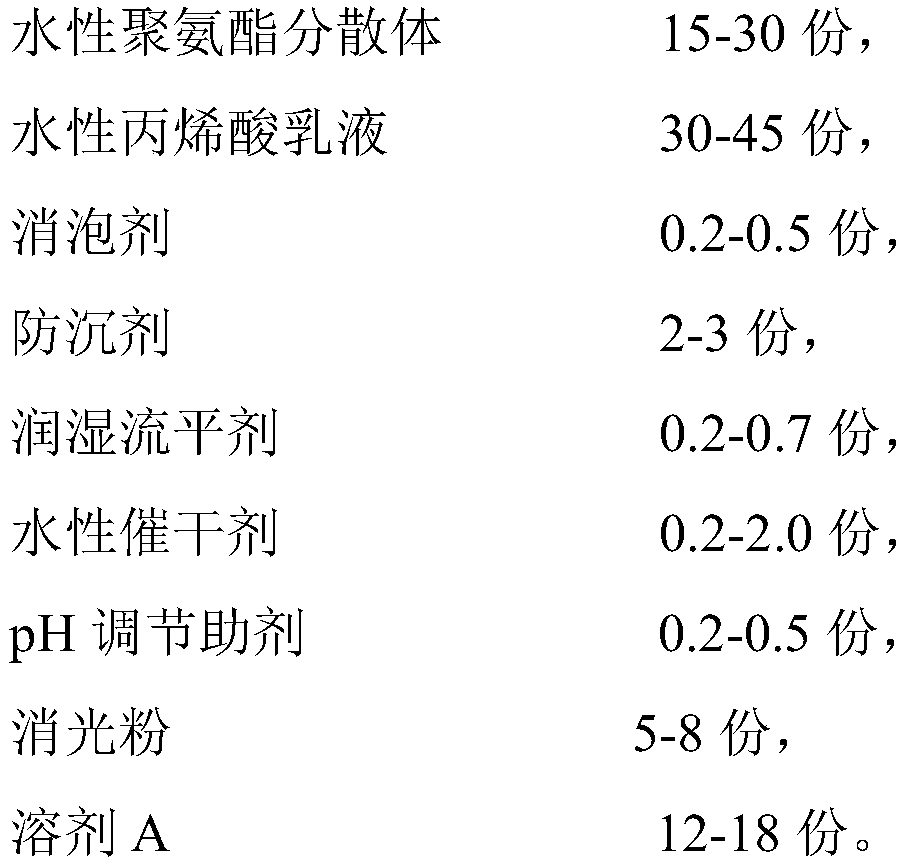

[0044] Wherein, the component A resin paint comprises the following components and parts by weight:

[0045]

[0046] Described component B curing agent comprises following components and weight part content:

[0047]HW2100 55 copies,

[0048] 33 parts of solvent B.

[0049] Solvent A is prepared by mixing 10 parts of deionized water, 2 parts of dipropylene glycol methyl ether and 6 parts of dipropylene glycol butyl ether.

[0050] Solvent B is made by mixing 20 parts of BGA (butyl glycol ether acetate).

[0051] The preparation method of the water-based elastic paint of the present embodiment quick-drying ultra-long pot life specifically comprises the following steps:

[0052] (1) Add the polyurethane dispersion and the acrylic emulsion into the dispersing tank in parts by weight, stir evenly, then a...

Embodiment 2

[0061] A water-based elastic paint with fast drying and super long pot life is composed of component A resin paint and component B curing agent in a weight ratio of 2:1;

[0062] Wherein, the component A resin paint comprises the following components and parts by weight:

[0063]

[0064] Described component B curing agent comprises following components and weight part content:

[0065] HW2100 55 copies,

[0066] Solvent B 25 parts.

[0067] Solvent A is prepared by mixing 10 parts of deionized water, 2 parts of dipropylene glycol methyl ether and 6 parts of dipropylene glycol butyl ether.

[0068] Solvent B is made by mixing 20 parts of BGA (butyl glycol ether acetate).

[0069] The preparation method of the water-based elastic paint of the present embodiment quick-drying ultra-long pot life specifically comprises the following steps:

[0070] (1) Add the polyurethane dispersion and the acrylic emulsion into the dispersing tank in parts by weight, stir evenly, then add...

Embodiment 3

[0074] A water-based elastic paint with fast drying and long pot life is composed of component A resin paint and component B curing agent in a weight ratio of 3:1;

[0075] Wherein, the component A resin paint comprises the following components and parts by weight:

[0076]

[0077] Described component B curing agent comprises following components and weight part content:

[0078] HW2100 55 copies,

[0079] Solvent B 20 parts.

[0080] Solvent A is prepared by mixing 10 parts of deionized water, 1 part of dipropylene glycol methyl ether and 4 parts of dipropylene glycol butyl ether.

[0081] Solvent B is made by mixing 20 parts of BGA (butyl glycol ether acetate).

[0082] The preparation method of the water-based elastic paint of the present embodiment quick-drying ultra-long pot life specifically comprises the following steps:

[0083] (1) Add the polyurethane dispersion and the acrylic emulsion into the dispersing tank in parts by weight, stir evenly, then add defoam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com