Extraction method of antimony triacetate

A technology of antimony triacetate and an extraction method, applied in the field of chemical industry, can solve the problems of large product volume, difficulty in controlling the particle size of antimony triacetate crystals, storage space in multiple packaging boxes and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

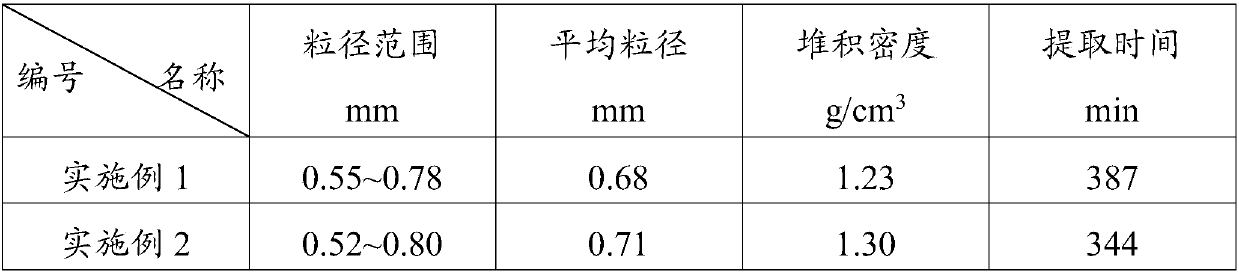

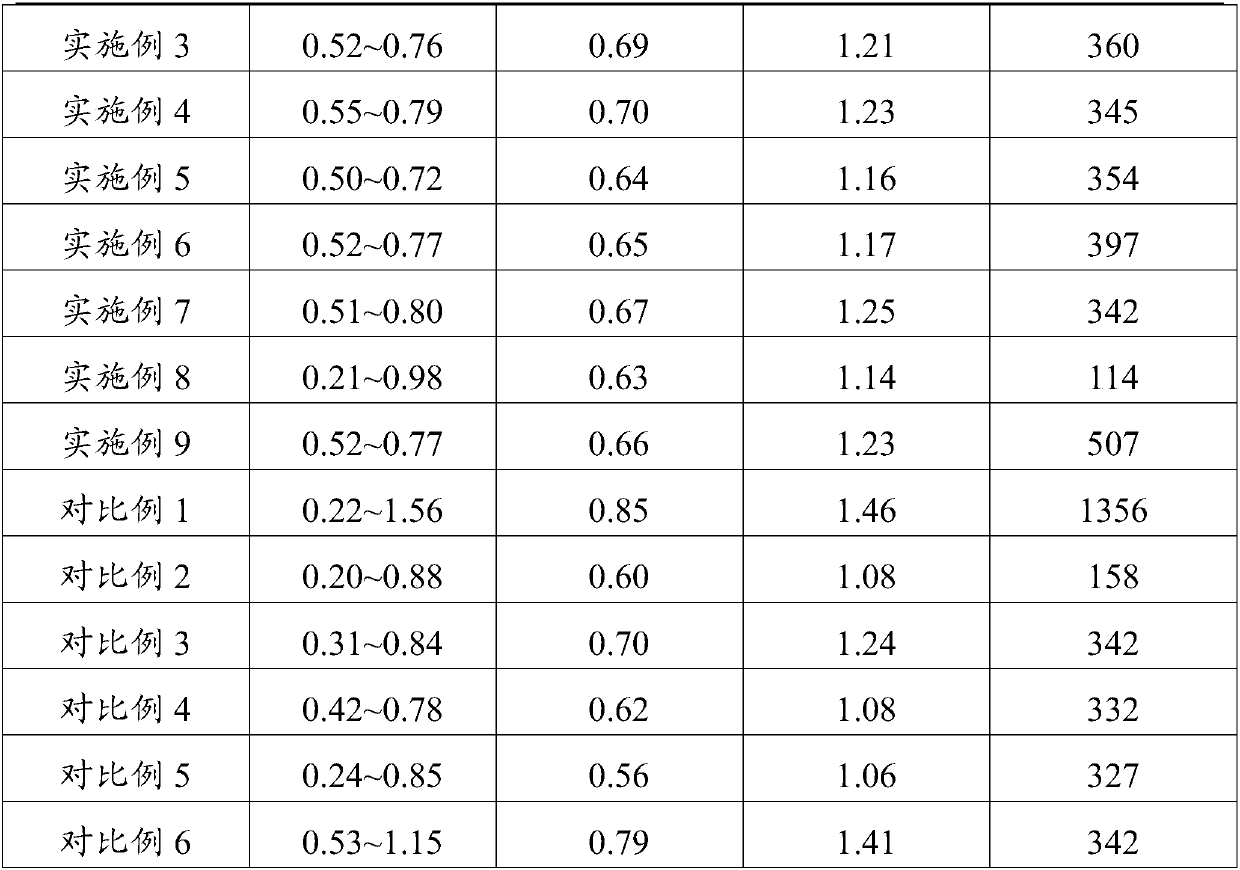

Examples

Embodiment 1

[0042] The extraction process of antimony triacetate in this embodiment is specifically as follows:

[0043] The toluene solution of antimony triacetate at a temperature of 113.5°C was placed in the crystallization kettle with an absolute pressure of 760mmHg. Start the predetermined crystallization program on the PLC. Under the control of the crystallization program, reduce the pressure of the crystallization kettle at a speed of 5mmHg / min. At the same time, the temperature of the toluene solution of antimony triacetate in the crystallization kettle will decrease until the temperature of the crystallization kettle is reduced to 98℃, absolute pressure It is 415.5mmHg, the predetermined program is automatically adjusted to reduce the pressure of the crystallization kettle at a rate of 2mmHg / min, while the temperature of the toluene solution of antimony triacetate in the kettle continues to decrease. Until there is obvious crystallization exotherm in the kettle, the temperature of t...

Embodiment 2

[0045] The extraction process of antimony triacetate in this embodiment is specifically as follows:

[0046] The toluene solution of antimony triacetate at a temperature of 118°C was placed in the crystallization kettle with an absolute pressure of 783.75 mmHg. Start the predetermined crystallization program on the PLC. Under the control of the crystallization program, reduce the pressure of the crystallization kettle at a speed of 6mmHg / min. At the same time, the temperature of the toluene solution of antimony triacetate in the crystallization kettle will decrease until the temperature of the crystallization kettle is reduced to 99℃, absolute pressure 431.25mmHg, the predetermined program is automatically adjusted to reduce the pressure of the crystallization kettle at a rate of 2.5mmHg / min, while the temperature of the toluene solution of antimony triacetate in the kettle continues to decrease. Until there is obvious crystallization exotherm in the kettle, the temperature of th...

Embodiment 3

[0048] The extraction process of antimony triacetate in this embodiment is specifically as follows:

[0049] A toluene solution of antimony triacetate at a temperature of 115.2°C was placed in a crystallization kettle with an absolute pressure of 768.6 mmHg. Start the predetermined crystallization program on the PLC. Under the control of the crystallization program, reduce the pressure of the crystallization kettle at a speed of 5.5 mmHg / min. At the same time, the temperature of the toluene solution of antimony triacetate in the crystallization kettle will decrease until the temperature of the crystallization kettle is reduced to 98.5°C. Press 423.5mmHg, the predetermined program is automatically adjusted to reduce the pressure of the crystallization kettle at a rate of 2.3mmHg / min, while the temperature of the toluene solution of antimony triacetate in the kettle continues to decrease. Until a significant crystallization exotherm occurs in the kettle, the temperature of the tolu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com