A rotary scraping film distillation and desalination device

A technology of distillation, desalination and rotary scraping, which is applied in the direction of evaporation, general water supply saving, chemical instruments and methods, etc. It can solve the problems of affecting heat transfer performance and water production capacity decline, and achieves enhanced heat transfer, reduced evaporation thermal resistance, and improved The effect of freshwater recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

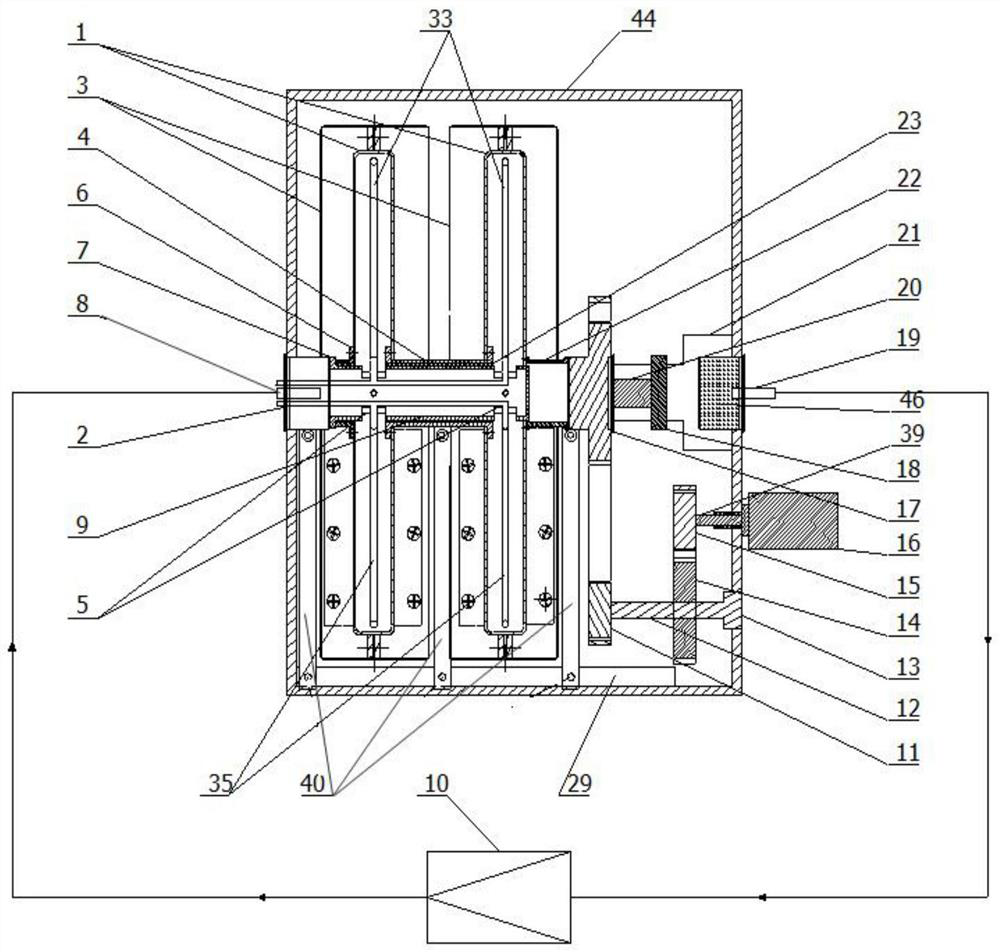

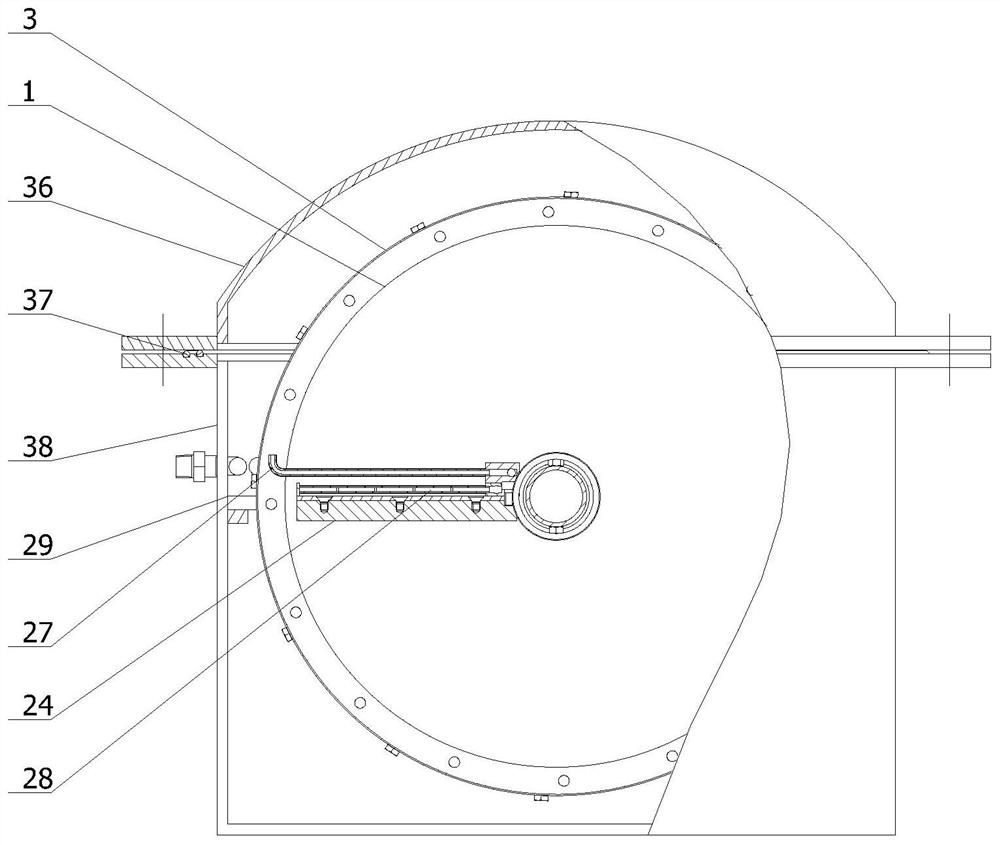

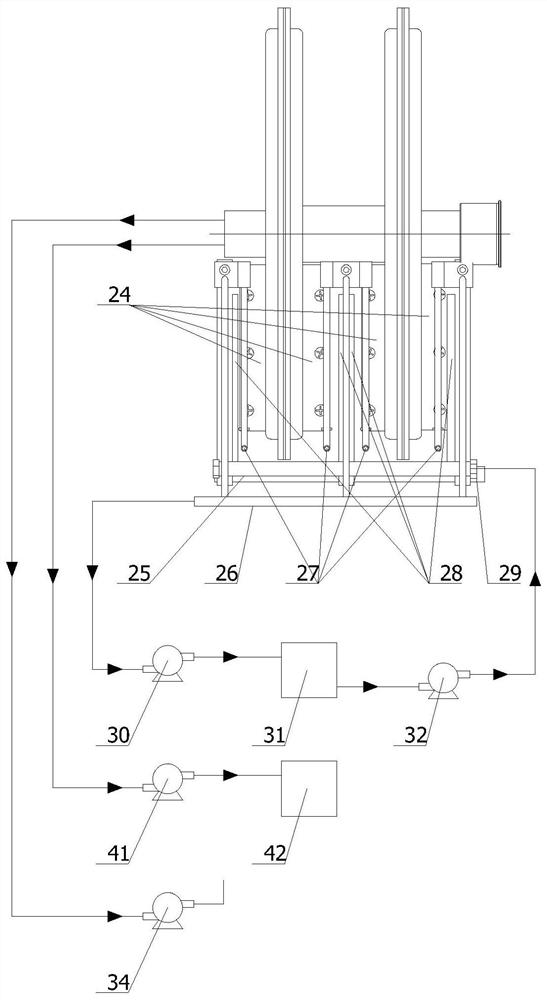

[0025] A rotary wiped film distillation and desalination device, such as figure 1 As shown, the device housing 44 is included, the bearing bracket 21 is installed at the center of the inner wall on the right side of the housing, the end rolling bearing 18 is fixedly installed at the left end of the bearing bracket 21, and the inner sleeve of the end rolling bearing 18 is worn from the left side. The driving pulley rotating shaft 20 is equipped with a large pulley 17 on the left end of the driven pulley rotating shaft 20, and the left side of the large pulley 17 is coaxially provided with a right segment hollow sleeve 22, a middle segment hollow sleeve 4 and a left segment hollow sleeve. Tube 6, the right end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com