Polyethylene plastic film cut-off and winding device for food cling wrap films

A technology for food preservation and plastic film, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of high equipment cost, film creases, unfavorable production efficiency, etc., and achieves simple and convenient use and operation. Reduce the probability of occurrence, good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

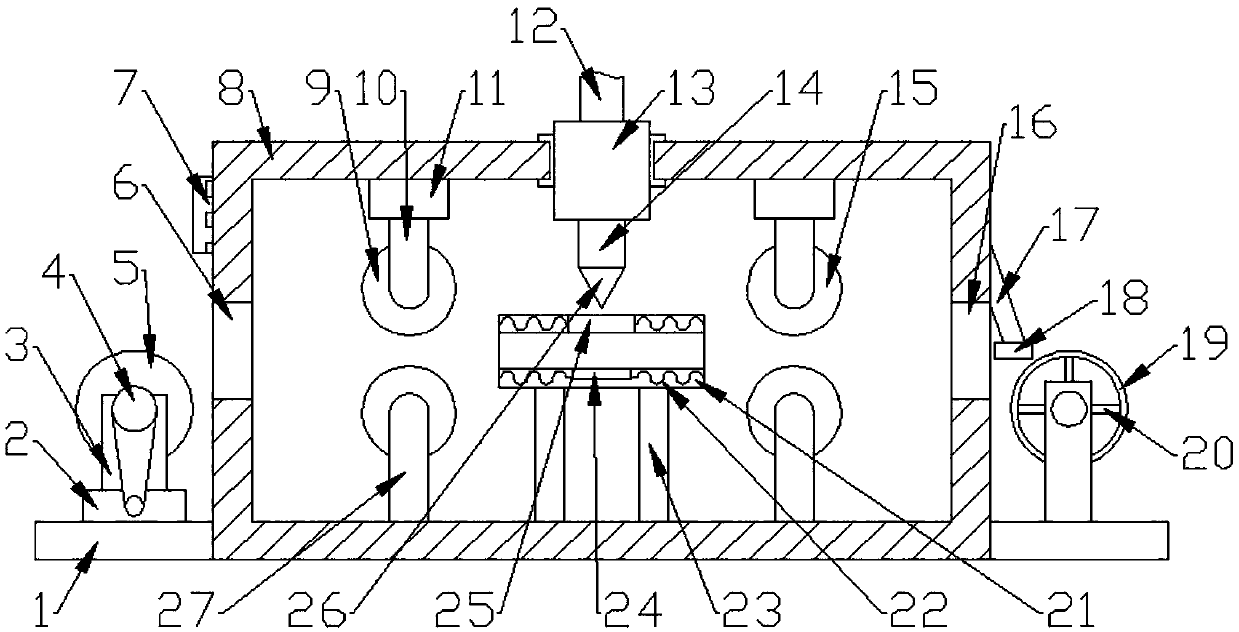

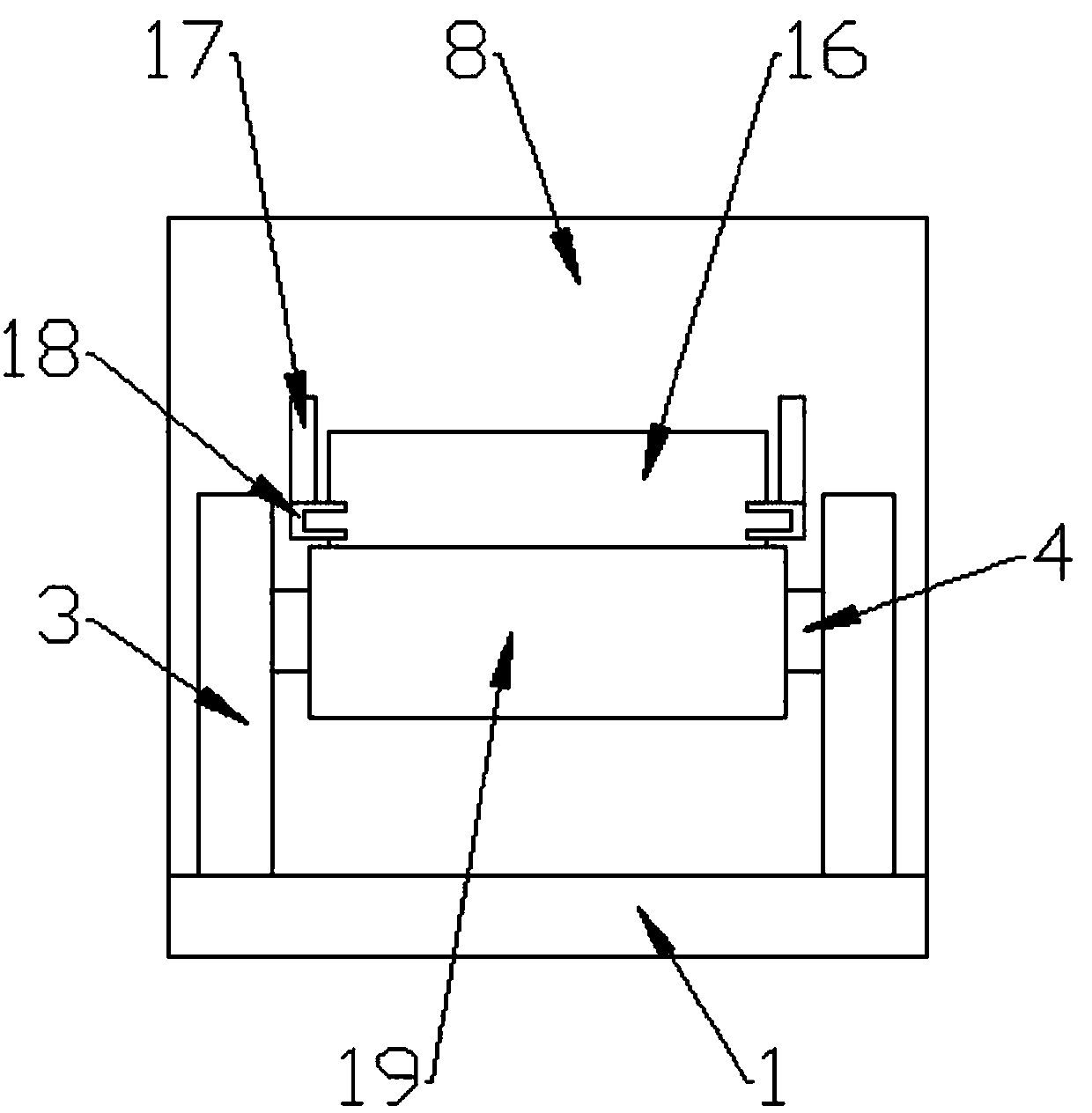

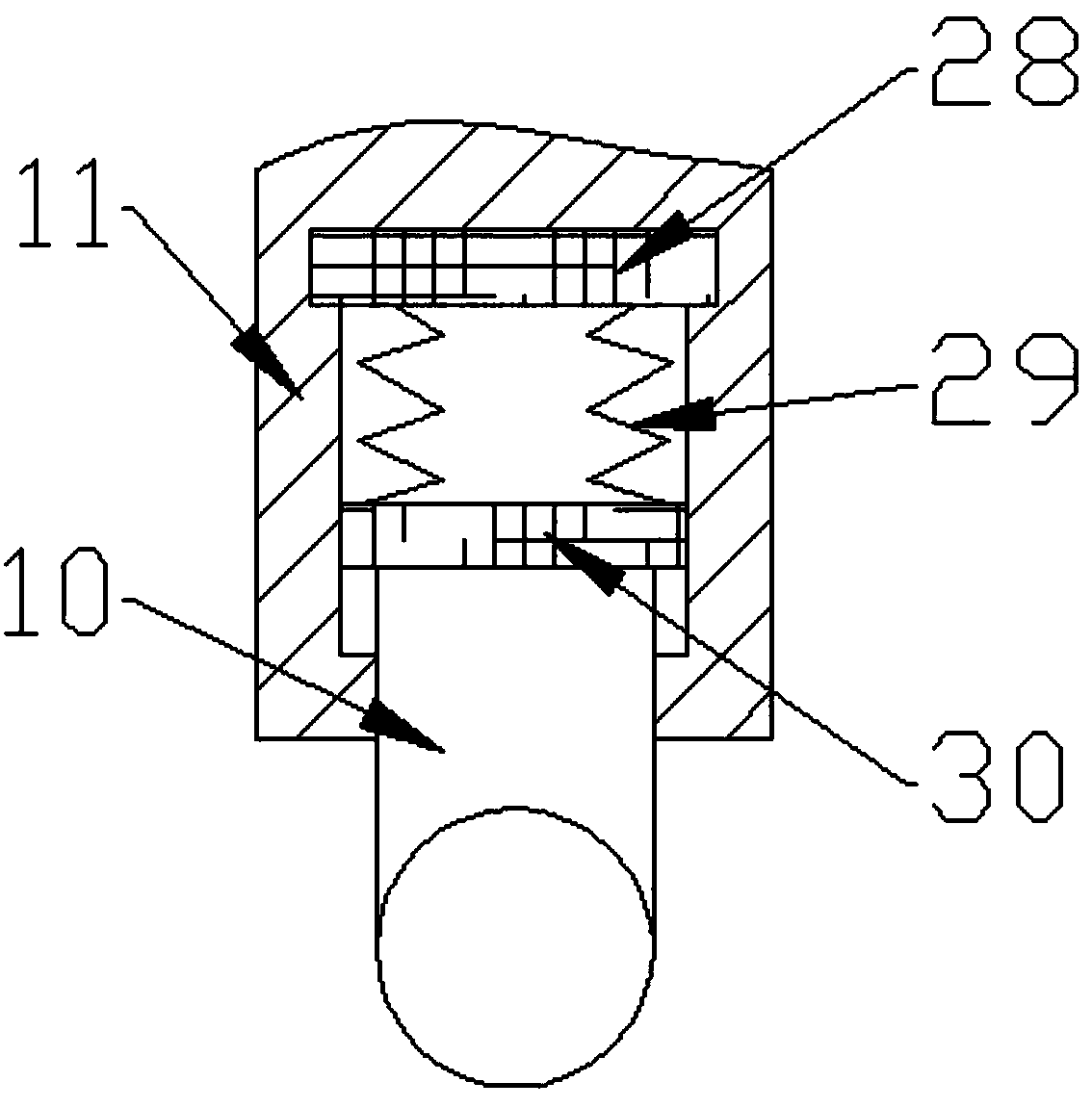

[0022] see Figure 1-5 , a polyethylene plastic film cut-off and winding device for food preservation film, comprising a cut-off box 8; The parts on the top provide installation space; the upper surface of the support seat 1 is fixed with a motor 2 by bolts; the motor 2 is placed outside the left side of the cut-off box 8, and the drive pulley 4 is connected to it to provide power for the unwinding of the plastic film ; The transmission pulley 4 is connected to the film roll 5 by the support 3, and the power output by the motor 2 is delivered to the film roll 5; 5 for support; the right side of the film roll 5 is provided with a film inlet 6; the film inlet 6 is opened in the middle part of the left side wall of the cut-off box 8, and a control switch 7 is installed above it to transport the plastic film to be cut into the box; The control switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com