Method for processing composite paper

A technology for compounding paper and paper, applied in the field of papermaking, can solve the problems of easy delamination and weak adhesion of compound paper, and achieve the effects of uniform distribution of adhesives, tight adhesion, and avoidance of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

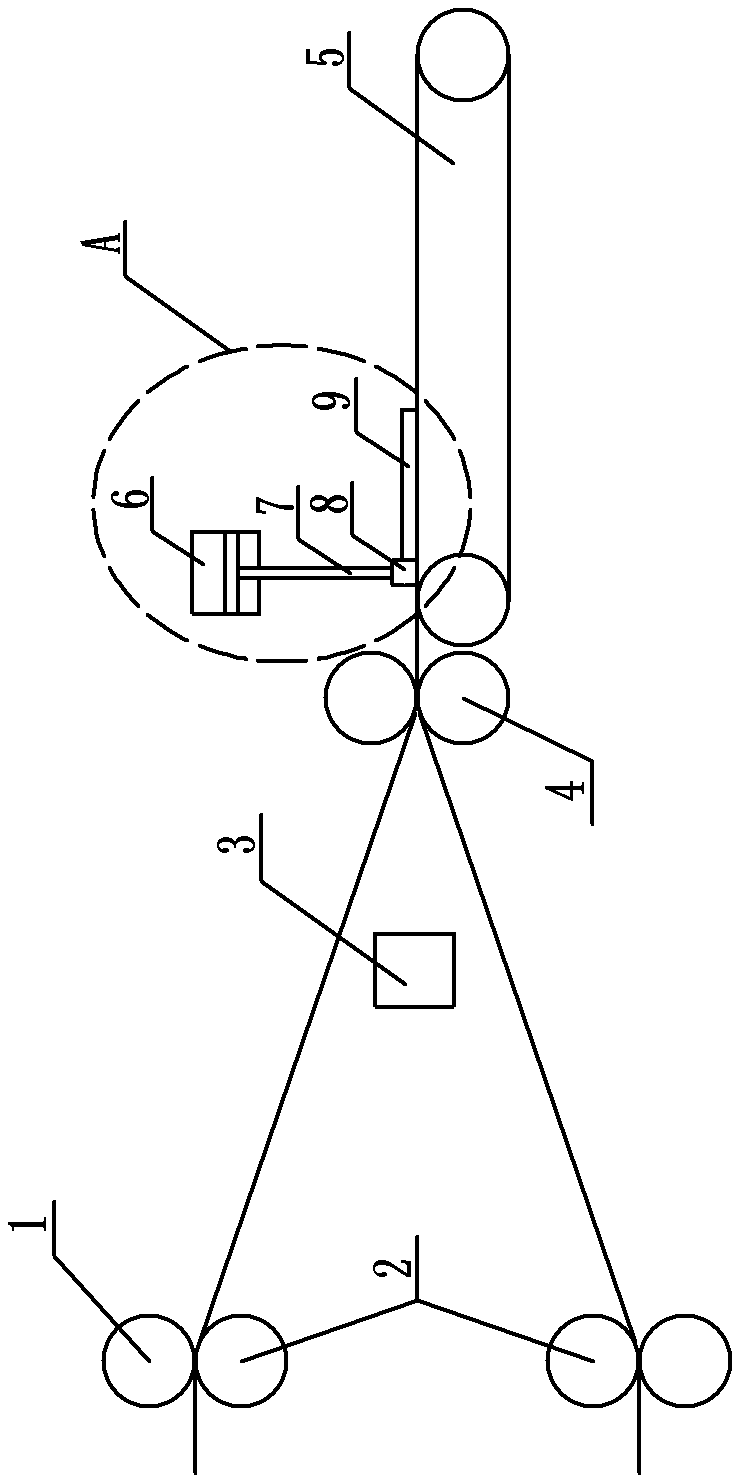

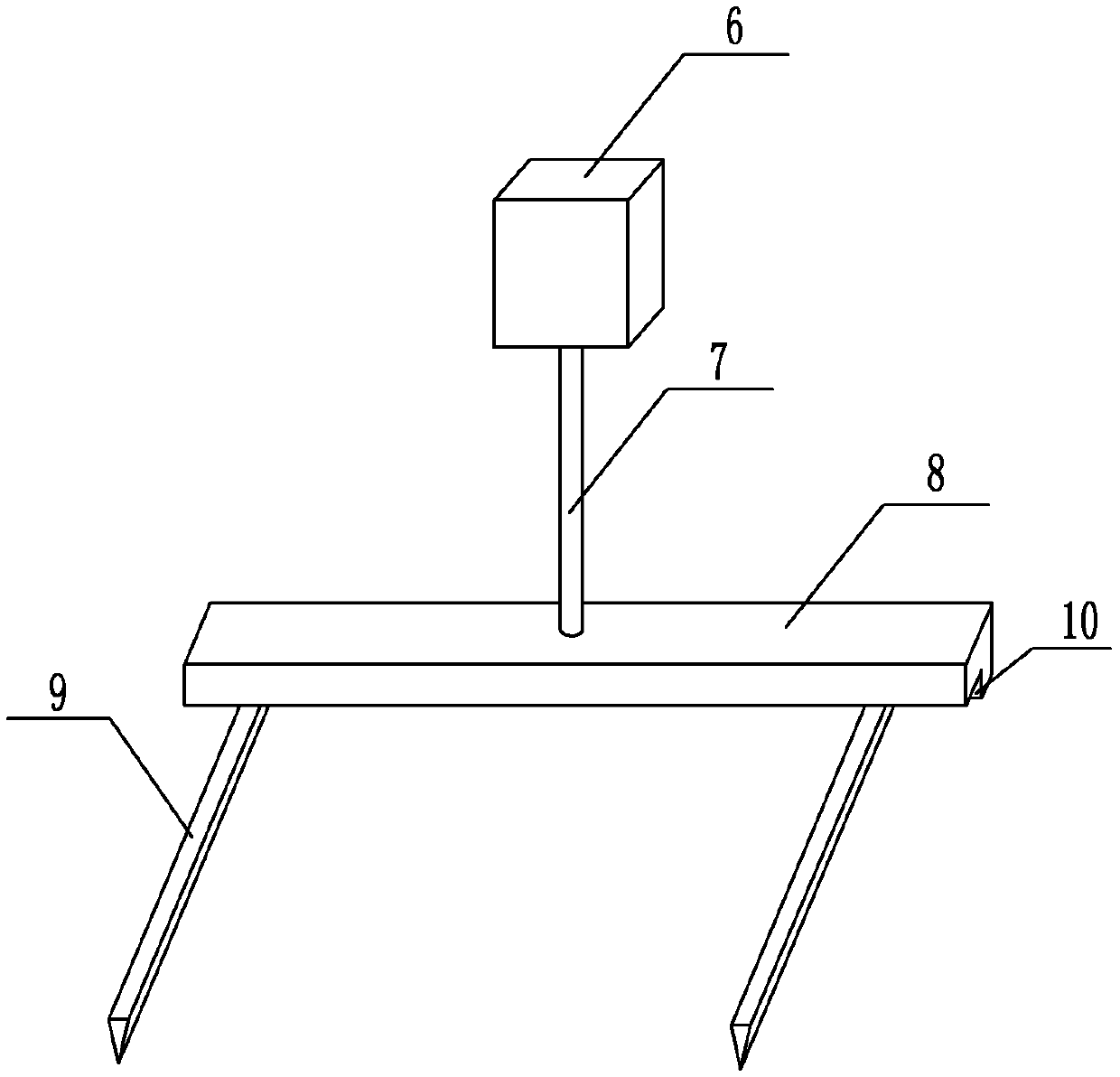

[0029] The reference signs in the drawings of the description include: guide roller 1, friction roller 2, two-way nozzle 3, squeeze roller 4, conveyor belt 5, first cylinder 6, piston rod 7, support plate 8, scraper 9, chute 10 .

[0030] The embodiment is basically as figure 1 , figure 2 Shown:

[0031] The method for composite paper processing is realized by means of a device for composite paper processing, the device for composite paper processing includes two paper supply mechanisms and a pressing mechanism, and a bonding mechanism is arranged between the two paper supply mechanisms , the extrusion mechanism includes two extrusion rollers 4, and a conveyor belt 5 is provided on one side of the extrusion mechanism. Paper, double-layer paper enters the next process along the conveyor belt 5;

[0032] The paper supply mechanism includes a guide roller 1 and a frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com