A sealed pressurized slurry pool device for an overhead light source 3D printer

A technology of 3D printer and slurry pool, which is applied in the field of 3D printing, can solve the problems of shortening printing time and achieve the effects of shortening printing time, enhancing adaptability, continuous downward movement and light curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

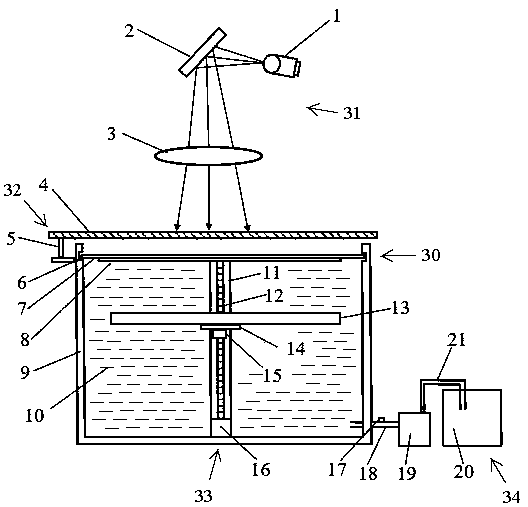

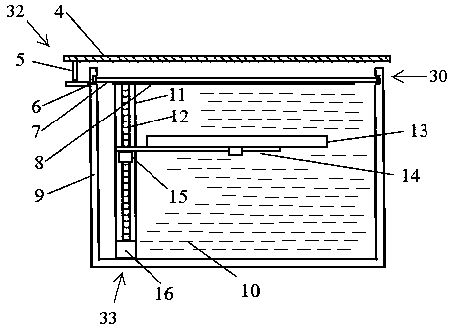

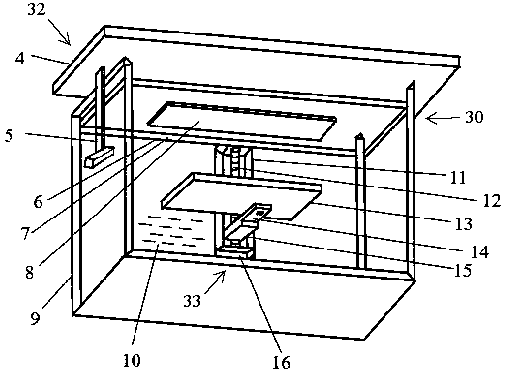

[0054] Hereinafter, the process flow of the sealed pressurized slurry tank device in working state according to the above-mentioned embodiments of the present invention will be described in detail in conjunction with specific examples. Specifically, in this embodiment, the booster pump 19 can be, for example, a peristaltic pump or a micropump that can withstand a pressure of 0-2 MPa, a flow rate of 0.001-400 ml / min, and a rotational speed of 0.1-200 rpm. The main slurry tank 9 can be made of stainless steel, for example, and has a size of L150×W150×H150mm˜L800×W800×H600mm. The transparent sealing plate 7 can be, for example, an acrylic plate with high light transmittance. The release layer 8 can be, for example, a release film with high light transmittance. The LED light source 1 may be, for example, an ultraviolet LED light source with a rated power of 20W and a wavelength of 365nm. The DMD device 2 can be, for example, a product of Texas Instruments.

[0055] Specifically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com