How to make a magnetic pole of a motor

A manufacturing method and magnetic pole technology, which are applied in the field of motor magnetic pole production and motor magnetic poles, can solve the problems of insufficient position accuracy, influence on magnetic field distribution, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

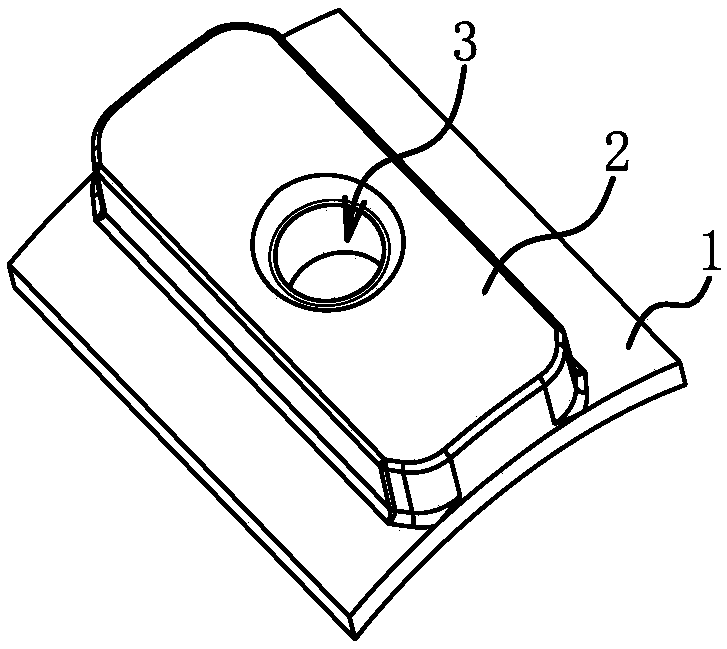

[0039] Such as Figure 1-2 As shown, the magnetic pole includes a pole shoe 1 in the shape of an arc and a sheet and a pole core 2 located in the middle of the convex surface of the pole shoe 1 . The length of the pole shoe 1 is slightly longer than that of the pole core 2, and the four corners of the pole core 2 perpendicular to the pole shoe 1 are arc-shaped.

[0040] There are threaded holes 3 on the magnetic pole, so that the magnetic pole is suitable for solid connection with the shell by bolts; according to the actual connection method between the magnetic pole and the shell, the magnetic pole structure can be flexibly adjusted. If the magnetic pole is connected to the shell by welding, there is no need to process the threaded hole 3 on the magnetic pole .

[0041] The manufacturing method of the magnetic pole of the motor is carried out in sequence according to the steps of blank selection, preforming, forming and trimming. through processing Figure 1-2 The example ...

Embodiment 2

[0049] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described redundantly, only the differences will be described, and the differences lie in:

[0050] Such as Figure 24 As shown, the concave corner of the pole shoe 1 in the magnetic pole is a plane 1a.

[0051] The manufacturing method of the magnetic pole of the motor is carried out in sequence according to the sequential steps of blank selection, preforming, forming, primary edge trimming, shaping and secondary edge trimming. The steps of blank selection, preforming and forming are the same as the steps of blank selection, preforming and forming in Embodiment 1, so no redundant description is given here.

[0052] The difference between one trimming in this embodiment and the trimming in Embodiment 1 is that there is no need to install a punching rod in the punching die, that is, there is no need to process the through hole 9 in this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com