Preparation method of oxide quantum dot modified graphene/titanium oxide photocatalysis material

A photocatalytic material and graphene technology, applied in the field of photocatalysis, can solve the problems of low utilization rate of sunlight and low photocatalytic efficiency, and achieve the effects of improving the utilization rate of visible light, improving the photon quantum yield, and reducing curling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

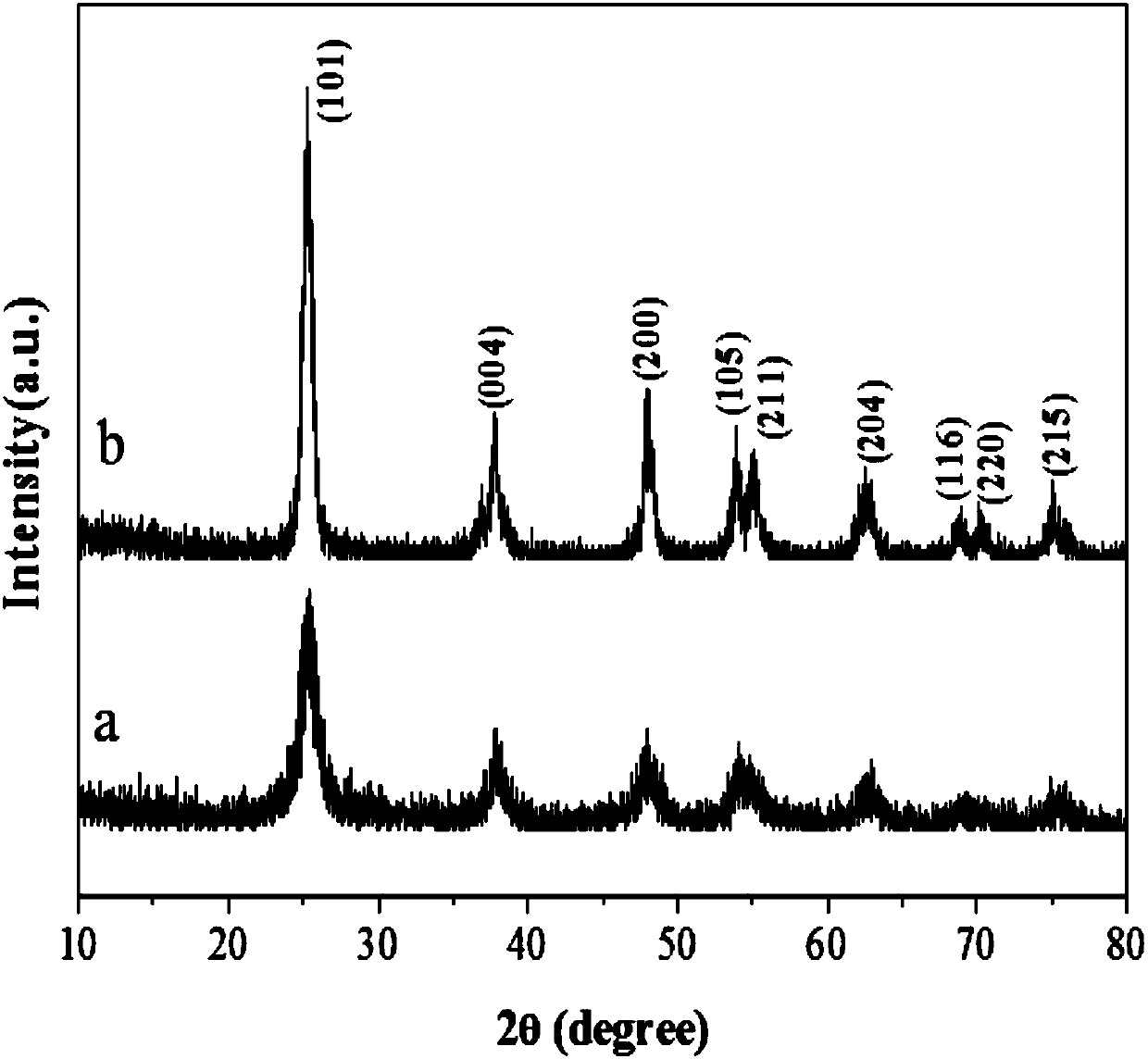

Image

Examples

Embodiment 1

[0036] (1) Add 10 g of molybdenum oxide powder into 800 mL of water, ultrasonically disperse for 40 minutes and then stir for 35 minutes to obtain a molybdenum oxide powder dispersion;

[0037] (2) Under ultrasonic vibration, carry out ultrasonic dispersion 3h to above-mentioned step (1) molybdenum oxide powder solution, centrifuge under 10000r / min to obtain molybdenum oxide quantum dot solution;

[0038] (3) 0.08g graphene was added to 70mL absolute ethanol and ultrasonically dispersed for 40min to obtain a graphene dispersion;

[0039] (4) Under the ultrasonic stirring situation, get 12g polyaniline and dissolve in 60mL dehydrated alcohol, after ultrasonic oscillation and stirring 50min, the polyaniline dispersion liquid is slowly poured in the graphene dispersion liquid that above-mentioned step (3) obtains, Obtain graphene-polyaniline absolute ethanol solution after ultrasonic stirring for 30min;

[0040] (5) Measure 20mL of absolute ethanol, 4mL of glacial acetic acid an...

Embodiment 2

[0048] (1) Add 8 g of manganese oxide powder into 1000 mL of water, ultrasonically disperse for 20 minutes, and then stir for 20 minutes to obtain a manganese oxide powder dispersion;

[0049] (2) Under ultrasonic vibration, the manganese oxide powder solution in the above step (1) was ultrasonically dispersed for 2 hours, and centrifuged at 9000r / min to obtain the manganese oxide quantum dot solution;

[0050] (3) Add 0.1 g of graphene to 30-70 mL of absolute ethanol for ultrasonic dispersion for 40 min to obtain a graphene dispersion;

[0051] (4) Under the ultrasonic stirring situation, get 10g polythiophene and dissolve in 50mL dehydrated alcohol, after ultrasonic oscillation and stirring 30min, pour polythiophene dispersion into the graphene dispersion that above-mentioned step (3) obtains slowly, Obtain graphene-polythiophene absolute ethanol solution after ultrasonic stirring for 15 min;

[0052] (5) Measure 15mL of absolute ethanol, 2mL of glacial acetic acid and 8mL ...

Embodiment 3

[0058] (1) Add 8g of tin oxide powder into 800mL of water, ultrasonically disperse for 40min and then stir for 40min to obtain tin oxide powder dispersion;

[0059] (2) Under ultrasonic oscillation, ultrasonically disperse the oxide powder in the above step (1) for 3 hours, and centrifuge at 10000r / min to obtain an oxide quantum dot solution;

[0060] (3) 0.1g of graphene was added to 70mL of absolute ethanol and ultrasonically dispersed for 40min to obtain a graphene dispersion;

[0061] (4) Under the ultrasonic stirring situation, get 12g polypyrrolidone and dissolve in 60mL dehydrated alcohol, after ultrasonic oscillation and stirring 60min, the polyacetylene dispersion is slowly poured in the graphene dispersion that above-mentioned step (3) obtains, Obtain graphene-polyacetylene absolute ethanol solution after ultrasonic stirring for 30min;

[0062] (5) Measure 15mL of absolute ethanol, 4mL of glacial acetic acid and 8mL of butyl titanate in sequence to form a mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com