Line-embedded flexible printed circuit and film pasting preparation technology thereof

A flexible circuit board and preparation process technology, which is applied in the secondary processing of printed circuits, coating of non-metallic protective layers, etc., can solve problems such as the inability to meet the needs of low-line spacing circuit boards, reduce the risk of short circuits, and be easy to implement and prepare. The effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

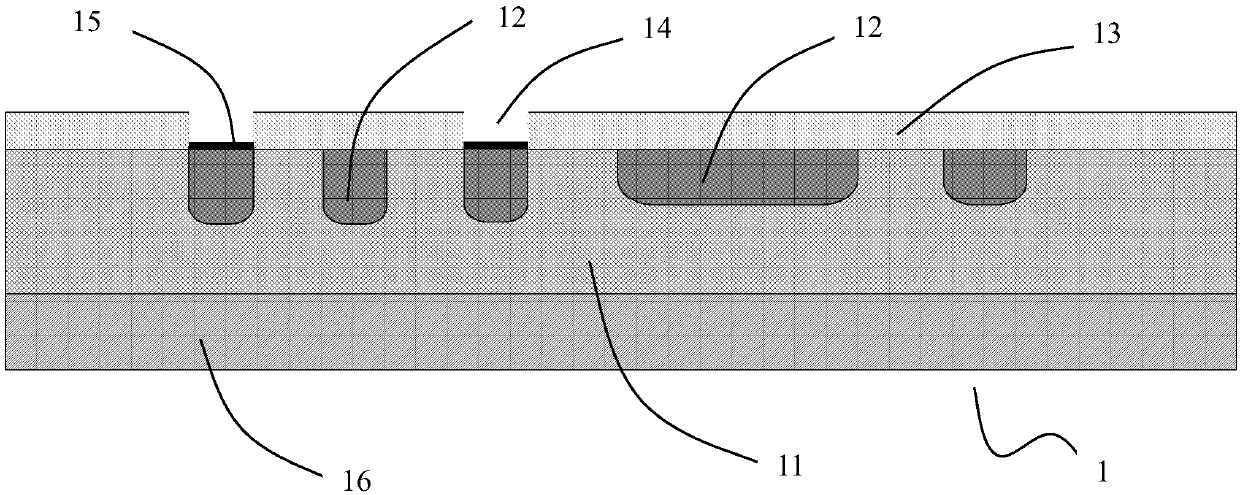

[0036] see Figure 1 to Figure 9 , a single-sided flexible circuit board 1 of this embodiment, including an adhesive layer 11, a circuit 12 embedded in the adhesive layer 11, a solder resist layer 13 located on one side of the adhesive layer 11, and a surface located on the other side of the adhesive layer 11 The protective layer 16 is provided with a plurality of pad areas 14 on the solder resist layer, the pad areas 14 are connected and penetrated with the circuit 12 , and the upper surface of the circuit 12 in the pad area 14 has a surface treatment layer 15 . In this embodiment, the material of the surface protection layer 16 is polyimide (PI), specifically thermoplastic polyimide (TPI), the material of the solder resist layer 13 is solder resist ink, and the surface treatment layer is a metal coating. From top to bottom, there are gold layer, palladium layer and nickel layer, and the thicknesses are 0.05-0.15 μm, 0.05-0.15 μm, and 3-8 μm in sequence.

[0037] This embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com