A kind of preparation method of selenized sodium alginate hydrogel

A technology of sodium alginate and alginic acid is applied in the field of preparation of selenium-enriched organic compounds, which can solve the problems of chemical cross-linking agents with large toxic and side effects, difficult to remove cross-linking agents, poor hydrogel performance, etc., and achieves high environmental friendliness. , High mechanical strength, good for observation and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

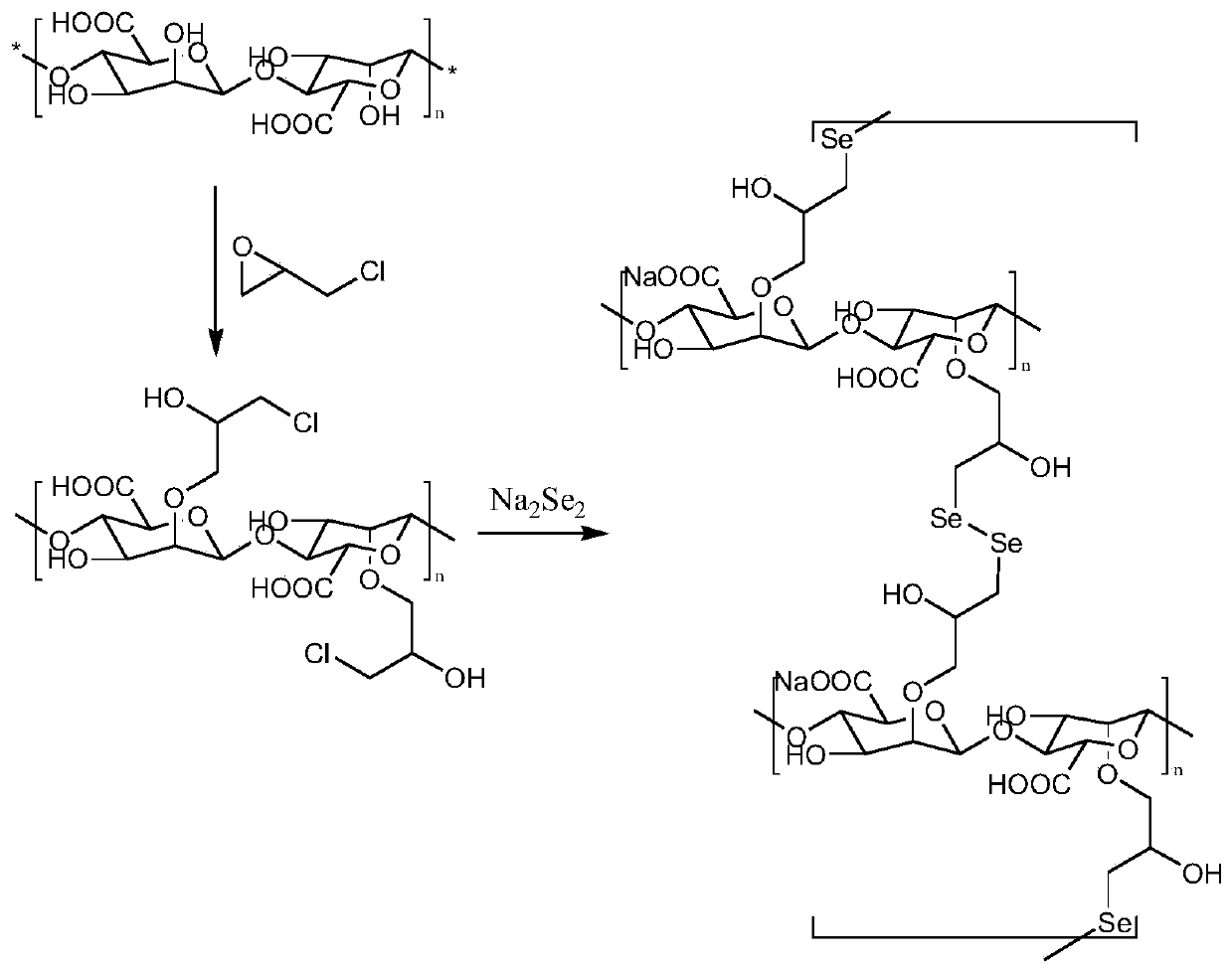

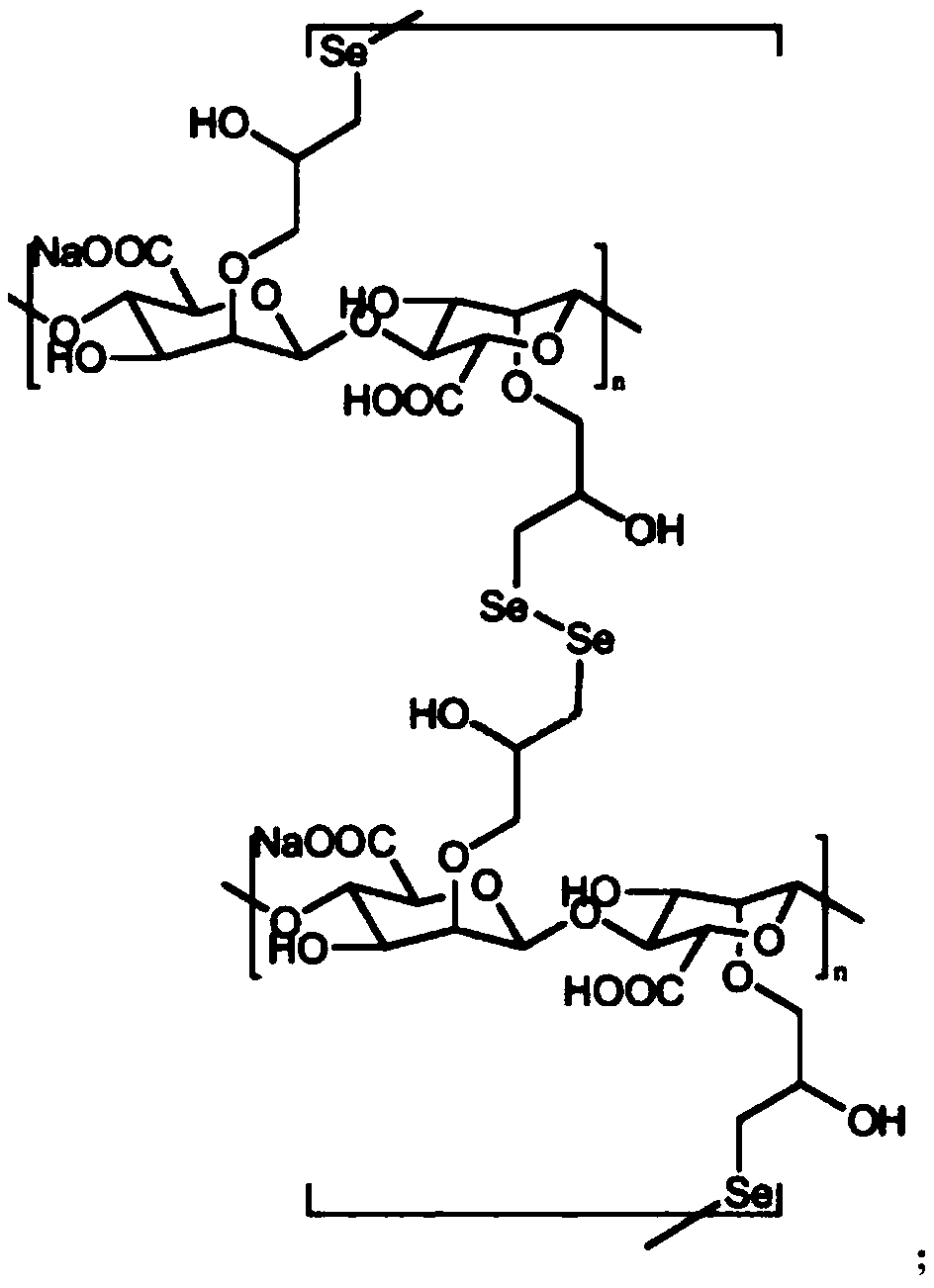

[0031] A kind of preparation method of selenized sodium alginate hydrogel proposed by the present invention comprises the following steps:

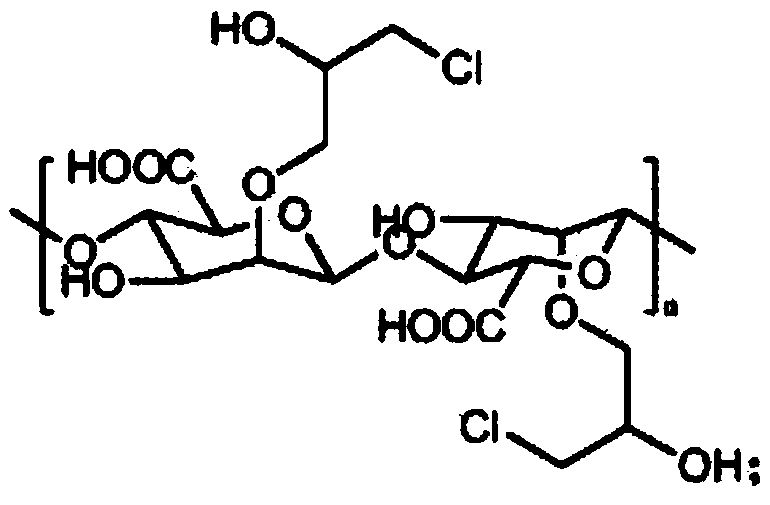

[0032] S1. Preparation of alginic acid pre-crosslinked product:

[0033] Add 10.8g of alginic acid into 65g of epichlorohydrin, stir and dissolve until uniformly dispersed, then raise the temperature and reflux for 4 hours. After the reaction is completed, use a rotary evaporator to evaporate the solvent in the reaction system to dryness to obtain a pre-crosslinked alginic acid 14.6g;

[0034] S2, preparation of selenized alginic acid:

[0035] Dissolve the alginic acid pre-crosslinked product obtained in step S1 in 100ml of dichloromethane, add 0.54g of solid sodium hydroxide, slowly add 54g of a 10% sodium diselenide aqueous solution dropwise at room temperature while stirring, and stir After reacting for 4 hours to obtain a reaction product, the obtained reaction product was washed twice with 200 ml of deionized water and then evapor...

Embodiment 2

[0039] A kind of preparation method of selenized sodium alginate hydrogel proposed by the present invention comprises the following steps:

[0040] S1. Preparation of alginic acid pre-crosslinked product:

[0041] Add 10.9g of alginic acid to 76.3g of methyl epichlorohydrin, stir and dissolve until uniformly dispersed, then raise the temperature and reflux for 4 hours. After the reaction is completed, use a rotary evaporator to evaporate the solvent in the reaction system to dryness to obtain alginic acid pre- Cross-linked product 15.8g;

[0042] S2, preparation of selenized alginic acid:

[0043] Dissolve the alginic acid pre-crosslinked product obtained in step S1 in 100 ml of ethyl acetate, add 0.68 g of SDS, slowly add 108 g of 10% sodium diselenide aqueous solution dropwise at room temperature while stirring, and stir for 4 hours to obtain a reaction product, the resulting reaction product was washed twice with 200ml deionized water and then evaporated to dryness to obt...

Embodiment 3

[0047] A kind of preparation method of selenized sodium alginate hydrogel proposed by the present invention comprises the following steps:

[0048] S1. Preparation of alginic acid pre-crosslinked product:

[0049] Add 10.6g of alginic acid to 84.8g of epichlorohydrin, stir and dissolve until uniformly dispersed, then raise the temperature and reflux for 4 hours. After the reaction is completed, use a rotary evaporator to evaporate the solvent in the reaction system to dryness to obtain alginic acid pre-crosslinked 14.9g;

[0050] S2, preparation of selenized alginic acid:

[0051] Add the alginic acid pre-crosslinked product obtained in step S1 and dissolve it in 100ml of chloroform, add 1.08g of sodium cetyl sulfate, and slowly add 160g of a 10% sodium diselenide aqueous solution dropwise at room temperature while stirring, Stirring and reacting for 4 hours to obtain a reaction product, the obtained reaction product was washed twice with 200 ml of deionized water and then eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com