Power battery explosion-proof valve welding assembly and welding method

A technology for welding components and power batteries, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of uneven shielding gas flow and pressure distribution, rough weld surface, low production yield, etc., to achieve protection The air flow and pressure are uniform, the weld surface is smooth and smooth, and the welding speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

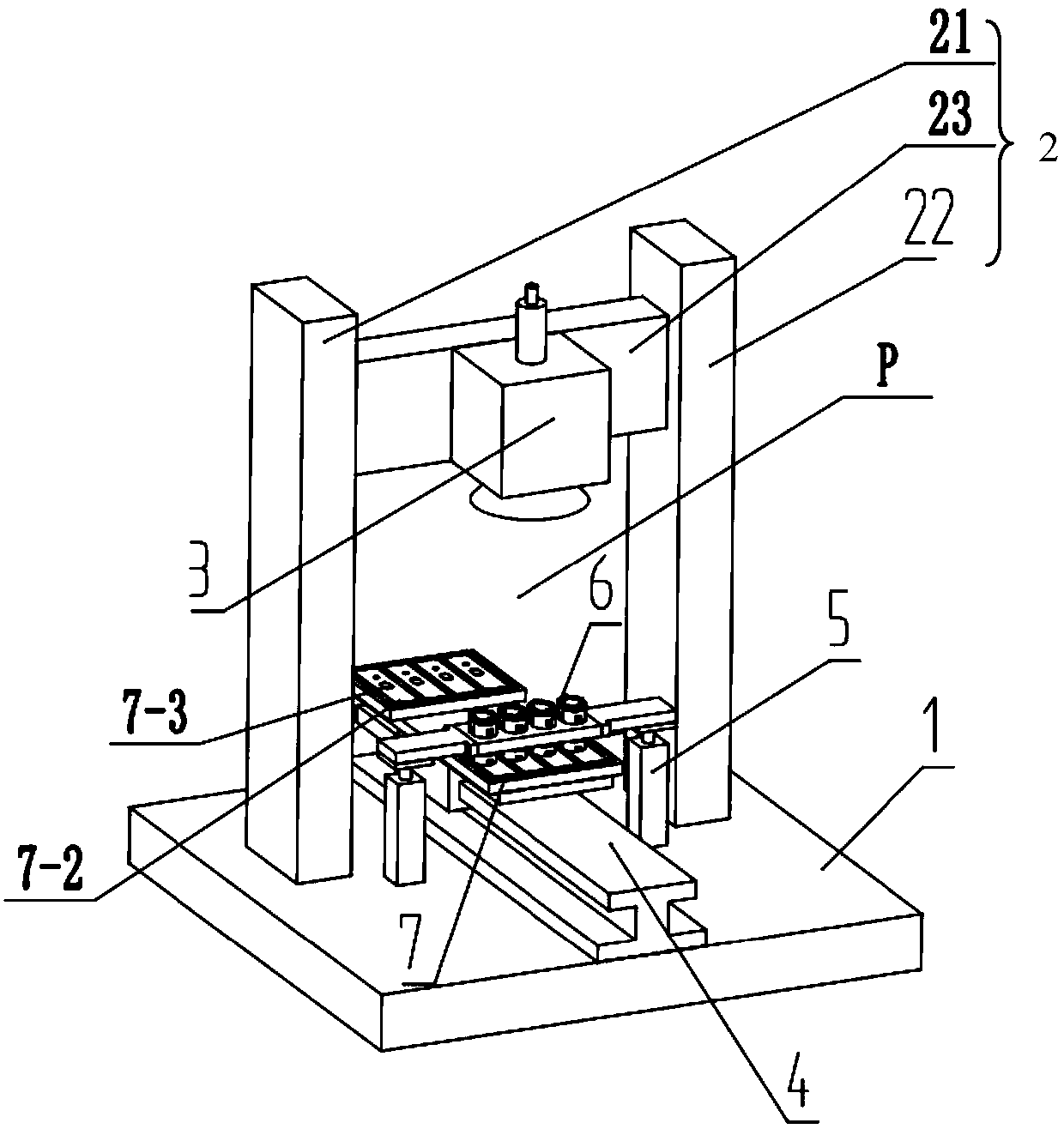

[0047] Such as figure 1 As shown, the power battery explosion-proof valve welding assembly of the present invention includes:

[0048] Platform 1, which can be made of hard materials such as marble, and its shape can be a cuboid structure of 1000*1000*100mm;

[0049] The gantry 2 is fixed on the upper surface of the platform 1; in this embodiment, the gantry 2 specifically includes: a first column 21, a second column 22, and a bridge connecting the first column 21 and the second column 22 The beam 23, the first column 21, the second column 22 and the beam 23 enclose a movable space P that can pass through; the beam 23 can move up and down, and its height is adjustable. In this embodiment, the distance between the bottom of the beam 23 The height of the upper surface of the platform 1 is 400-1000mm (preferably 800mm);

[0050] The galvanometer welding assembly 3 is connected to the gantry 2, more specifically, the galvanometer welding assembly 3 is connected to the middle of ...

Embodiment 2

[0067] This embodiment provides a method for welding an explosion-proof valve of a power battery, which includes the following steps:

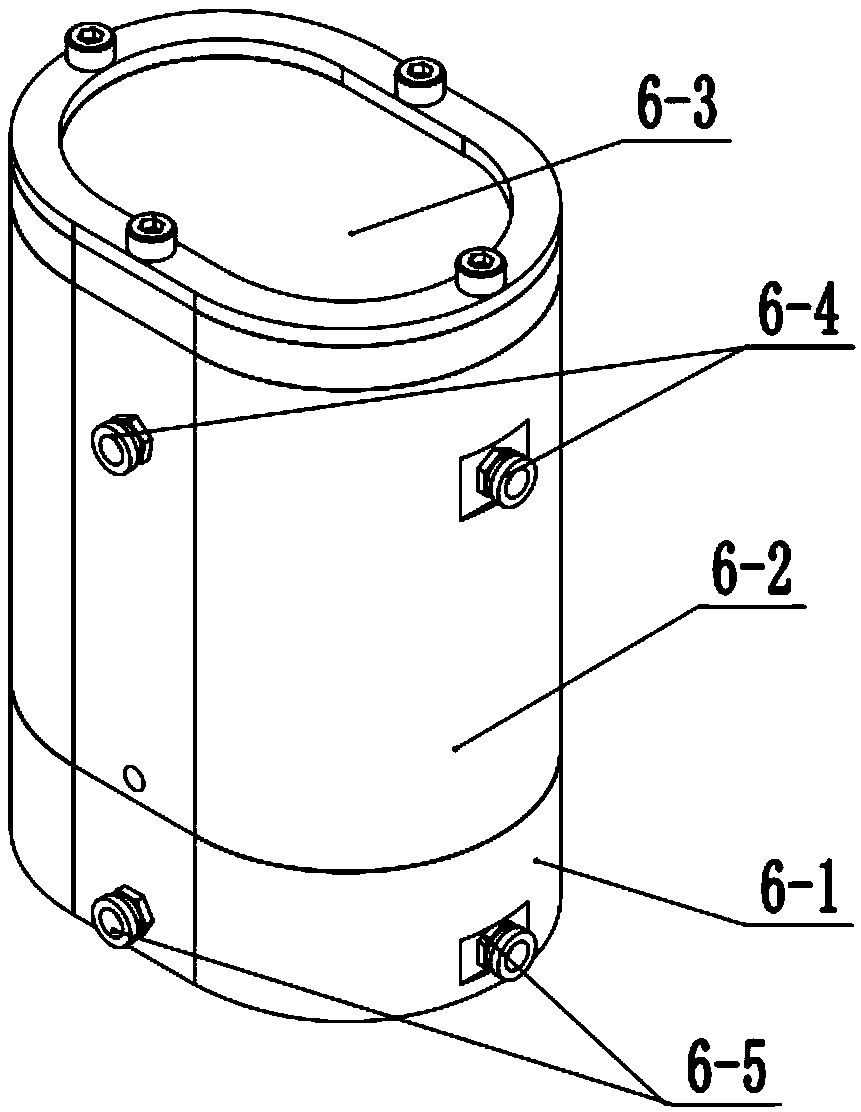

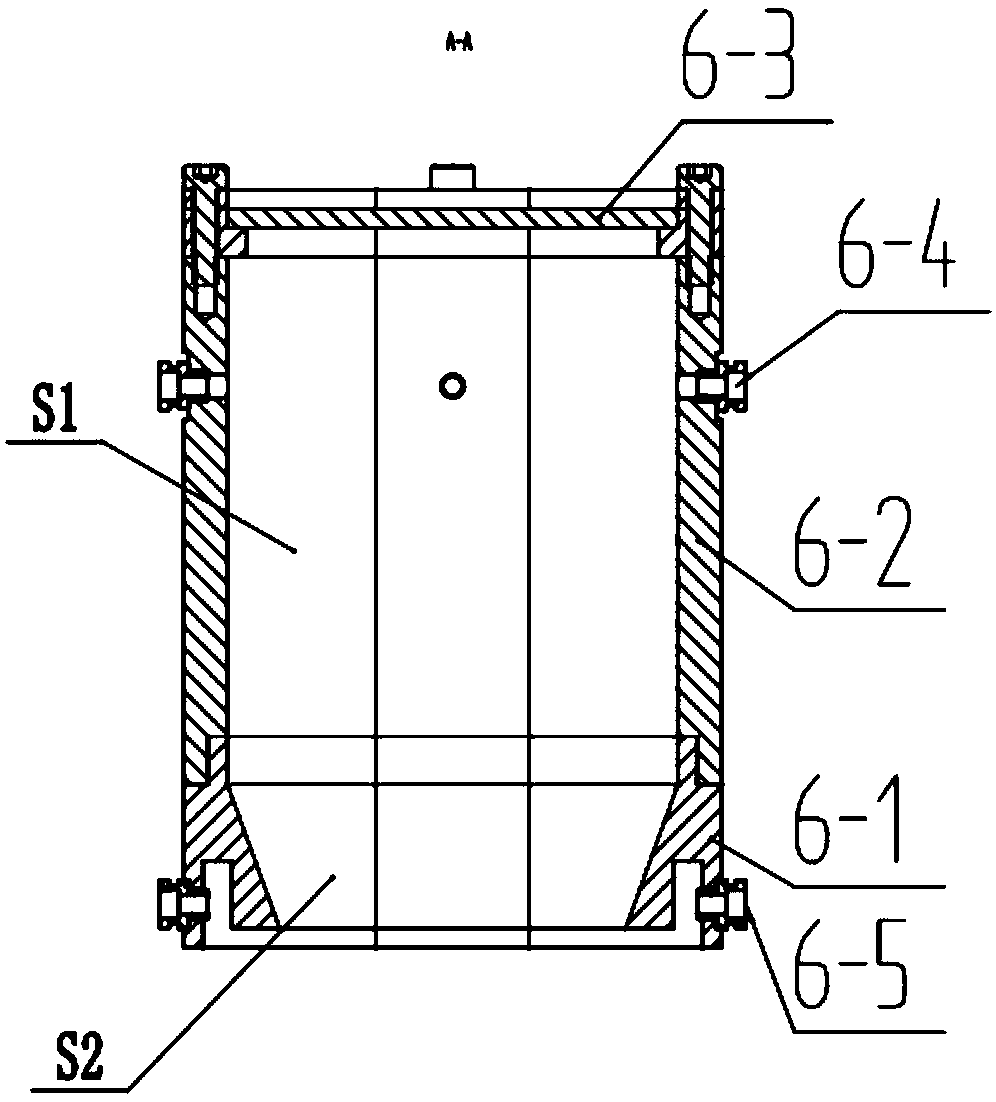

[0068] S1. Set up the gantry and the moving assembly on the platform, install the galvanometer welding assembly on the beam of the gantry, and install the blowing device above the moving assembly; and perform pre-spot welding before welding, and at the same time Set the energy gradual and gradual out waveform;

[0069] S2. Transport the tray to the bottom of the air blowing device through the moving assembly, adjust the height of the air blowing device, make the lower end surface of the lower part of the air blowing device fit the power battery cover, and make the The explosion-proof valve of the power battery to be welded is located in the second hollow part of the lower part of the blowing device;

[0070] S3. Input the protective gas through the protective gas intake component of the blowing device, and simultaneously extract the protectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com