Method for preventing copper pipe welding portion from generating verdigris due to oxidation in air

A technology for welding parts and copper pipes, applied in anti-corrosion coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as blackening, and achieve the effects of simple construction, prevention of blackening, and strong gloss retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

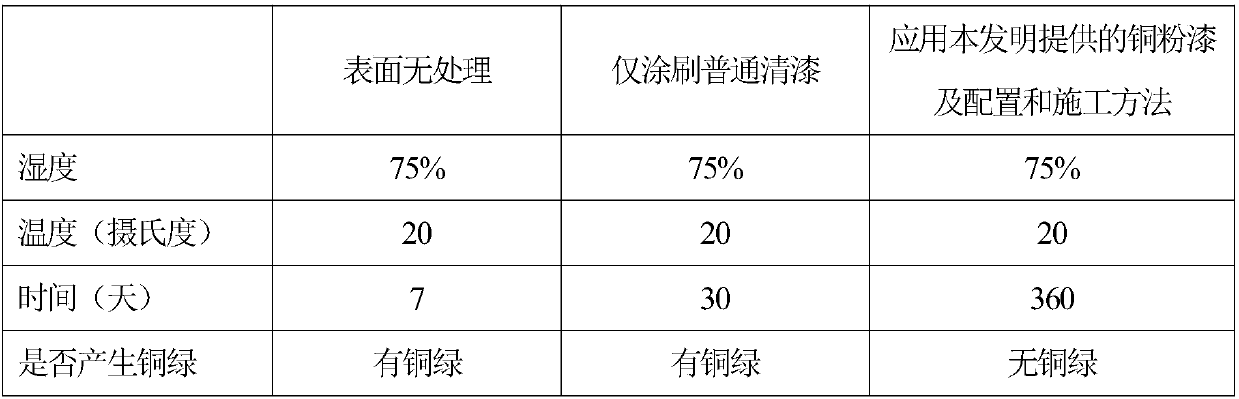

Embodiment 1

[0033] A method for preventing copper tube welding parts from being oxidized in the air to produce patina: cleaning the welding parts with hot water in time after the copper tube welding is completed to remove flux residues. Copper powder (particle size is 100 orders) and appropriate amount of antirust pigment are added in vessel and stirred evenly, then gradually add nitro varnish (25% of copper powder, 10% of antirust pigment, surplus is nitro varnish, described antirust pigment It is composite iron-titanium powder with a particle size of 325 mesh). Adjust the copper powder mixture into a slurry, stir well, and the construction viscosity is 24S. After the surface of the welding part of the copper pipe is dry, first apply 2-3 degrees of shellac paint to seal it, and then apply the prepared copper powder paint 2-3 degrees, and spray polyurethane varnish 2-3 degrees after the surface of the copper powder paint is dry. 3 degrees. At this point, the whole process of preventing ...

Embodiment 2

[0036] A method for preventing copper tube welding parts from being oxidized in the air to produce patina: cleaning the welding parts with hot water in time after the copper tube welding is completed to remove flux residues. Copper powder (particle size is 150 orders) and appropriate amount of antirust pigment are added in vessel and stirred evenly, then gradually add nitro varnish (copper powder 28%, antirust pigment 12%, surplus is nitro varnish, described antirust pigment It is composite iron-titanium powder with a particle size of 325 mesh)). Adjust the copper powder mixture into a slurry, stir well, and the construction viscosity is 26S. After the surface of the welding part of the copper pipe is dry, first apply 2-3 degrees of shellac paint to seal it, and then apply the prepared copper powder paint 2-3 degrees, and spray polyurethane varnish 2-3 degrees after the surface of the copper powder paint is dry. 3 degrees. At this point, the whole process of preventing coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com