Galvanized iron wire and white rusting agent compound for steel wire as well as method of making said galvanized iron wire and steel wire using said compound

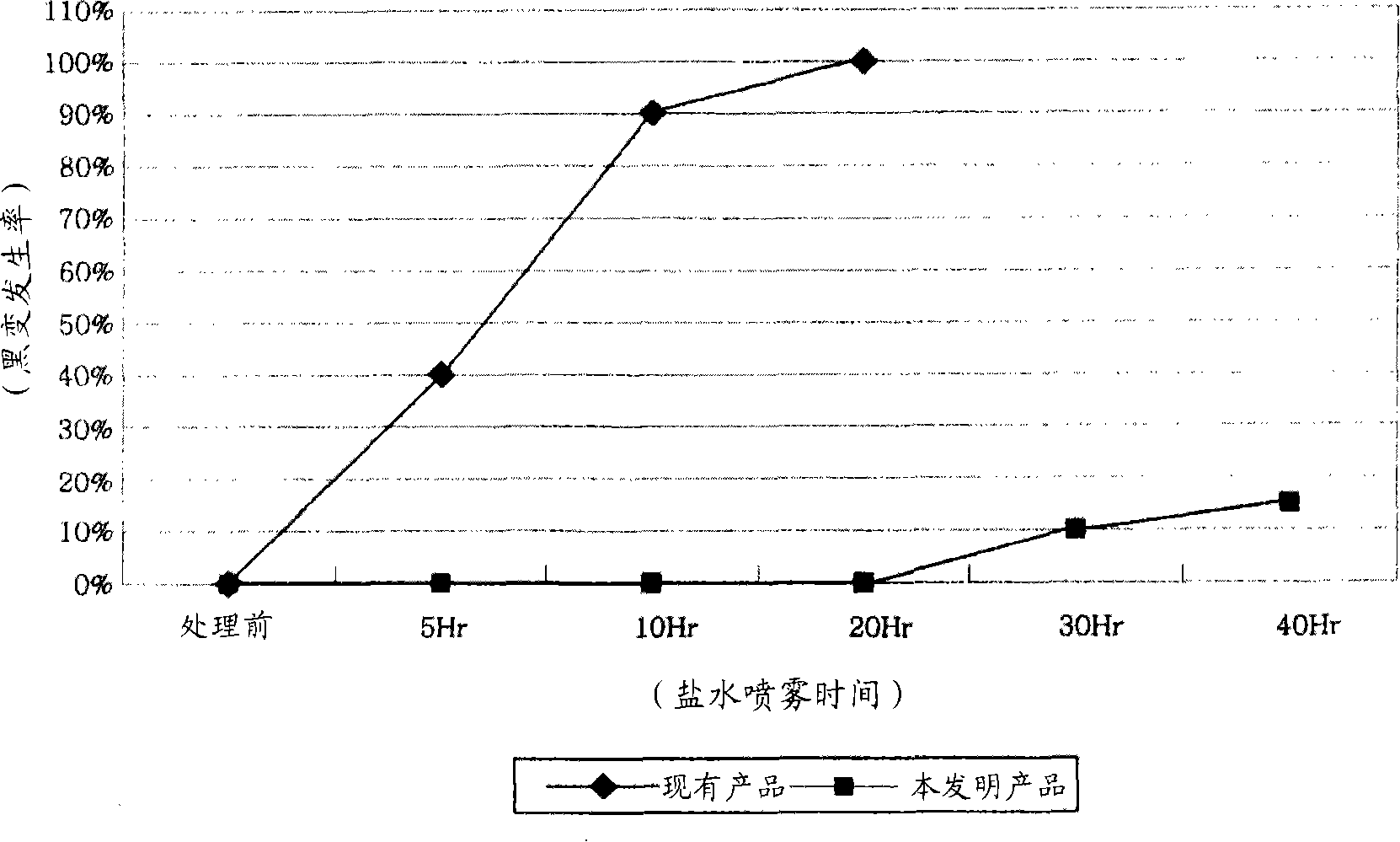

A galvanized iron wire and the technology of the manufacturing method are applied to the device for coating liquid on the surface, the metal material coating process, the coating, etc., and can solve the problems of galvanized iron wire and steel wire black change, white rust, and discoloration of the galvanized layer. Achieve the effects of preventing white rust and blackening, preventing treatment time, and preventing white rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

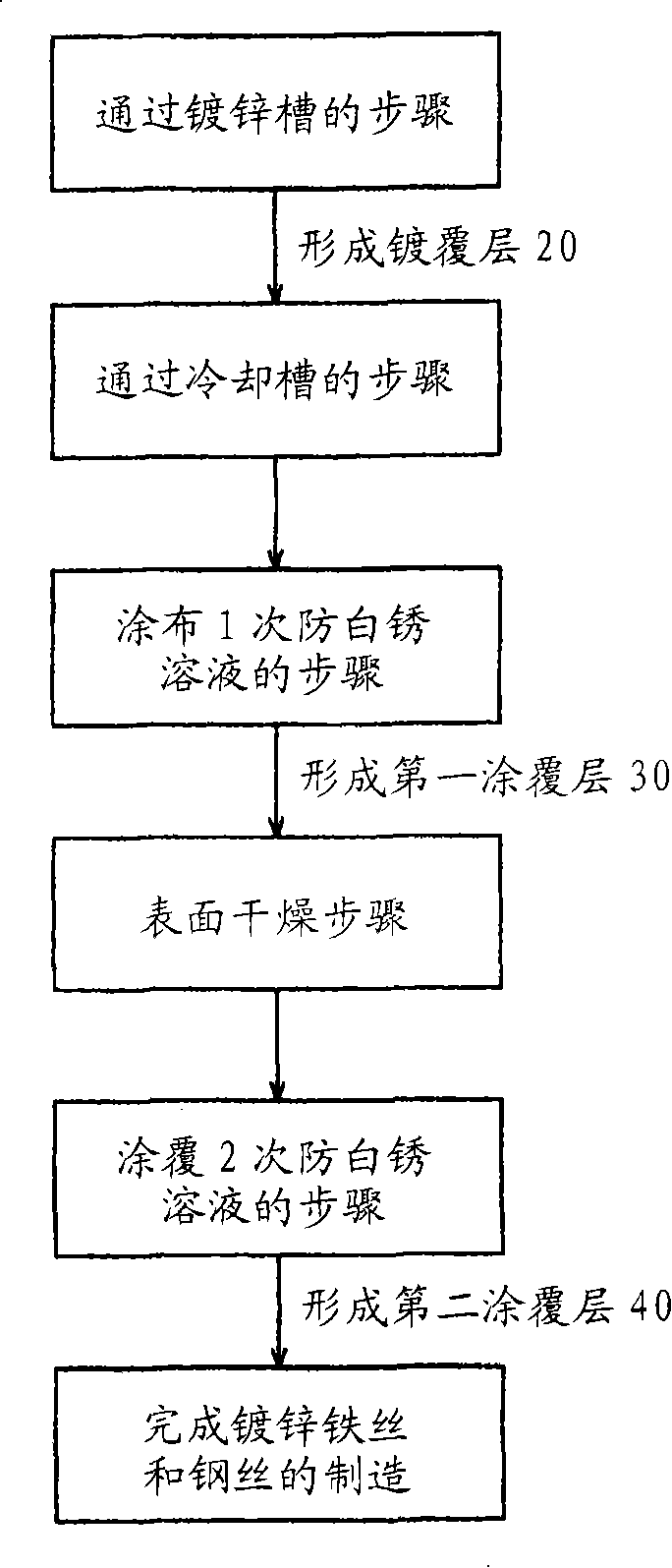

[0035] Such as figure 1 As shown, the proportion of trivalent chromium is limited to 0.01% to 0.5%. After mixing 1g / l to 50g / l of phosphoric acid and 2g / l to 10g / l of nitrite, add 0.1g / l to 1g The titanium component in the form of a metal salt per liter is mixed, and then 3% to 5% by weight of the mixture is mixed with 95% to 97% by weight of distilled water, and the mixture is diluted to produce a concentration of 3% to 5%. White rust solution.

[0036] Then, distilled water of 99 to 90% by weight is mixed and diluted with 1 to 10% by weight of ethoxylated amine to manufacture a secondary white rust preventing solution.

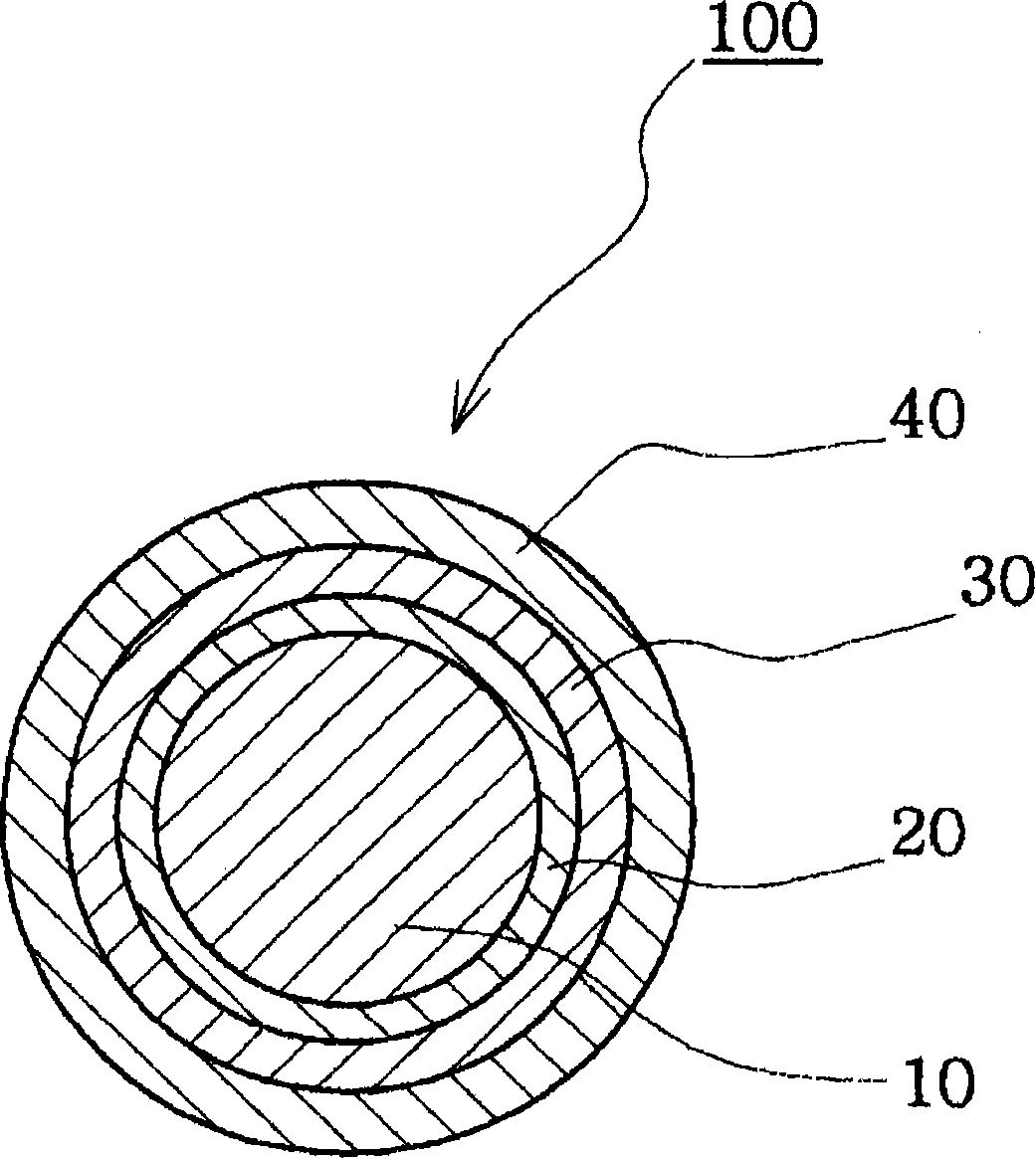

[0037] Such as figure 1 and figure 2 As shown, the wire 10 on which the plated layer 20 was formed by an ordinary method was immersed in the white rust preventing solution once for 1 to 5 seconds. Thereafter, after forming the first coating layer 30 of 0.1 μm to 0.5 μm, the surface is dried with natural air, and then it is further soaked in the anti-whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com