Method for preparing high-density polyethylene/ethylene-vinyl acetate blended hydrophobic microporous membranes

A technology of ethylene vinyl acetate and high-density polyethylene, applied in the field of membrane separation, to achieve the effect of easy operation, low crystallinity and high rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

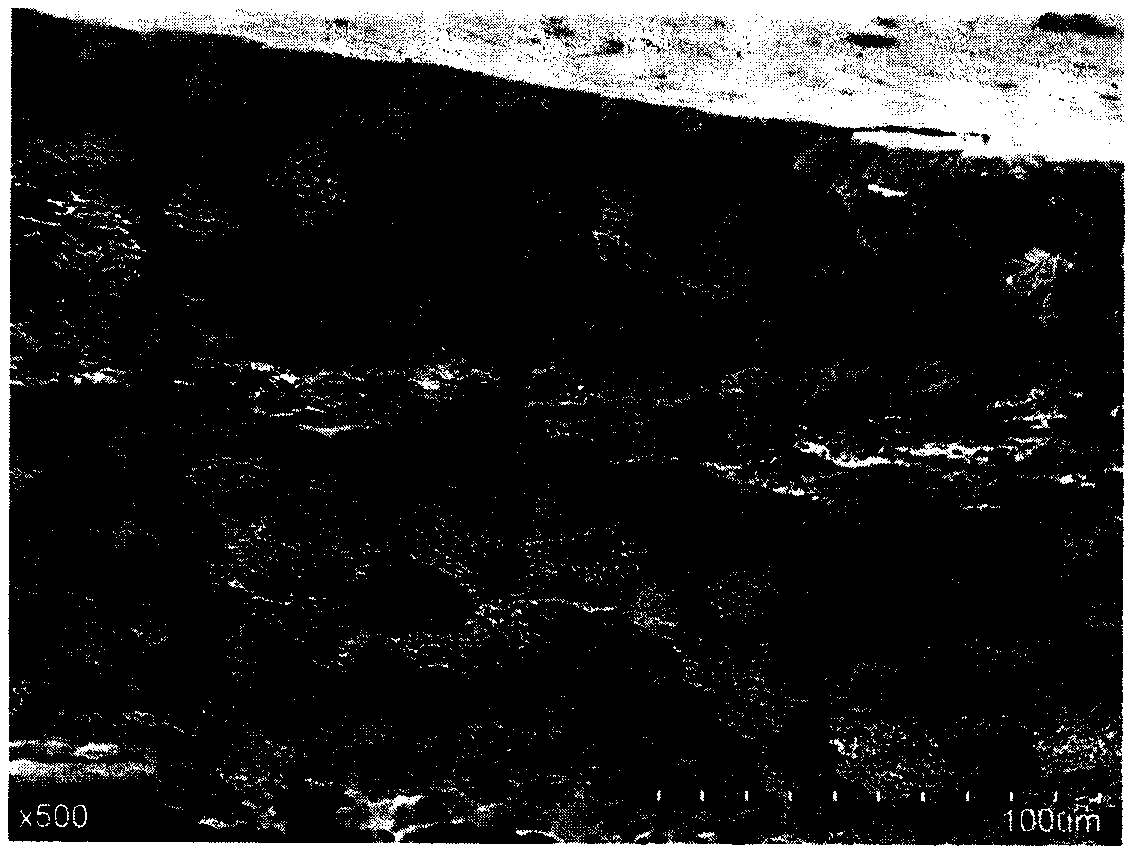

Image

Examples

Embodiment 1

[0020] (1) Weighing by weight: 70 parts of diphenyl ether diluent, 30 parts of other materials (high-density polyethylene / ethylene vinyl acetate / nucleating agent dibenzylidene sorbitol, mass ratio is 22.125 / 7.375 / 0.5;

[0021] (2) Add the mixed raw materials weighed in step (1) into the reactor, pass through nitrogen protection, heat to 180° C., stop stirring after 4 hours, let stand for 2 hours for degassing, and obtain a homogeneous casting solution;

[0022] (3) Apply the casting solution obtained in (2) to the surface of the polyester non-woven fabric and scrape it into a flat shape, the temperature of the scraped film is 180°C, and then enter it into a 25°C water tank to cool and solidify;

[0023] (4) Ultrasonic extraction of the film obtained in step (3) with an anhydrous ethanol extractant with a purity of 99.7% for 24 hours, and after the extraction is completed, put it in a vacuum oven at 30°C to dry to obtain a high-density polyethylene / ethylene acetic acid Ethyle...

Embodiment 2

[0026] (1) Weighing by weight: 70 parts of diphenyl ether diluent, 30 parts of other materials (high-density polyethylene / ethylene vinyl acetate / nucleating agent dibenzylidene sorbitol, mass ratio is 24.58 / 4.92 / 0.5;

[0027] (2) Add the mixed raw materials weighed in step (1) into the reactor for stirring, pass through nitrogen protection, heat to 200° C., stop stirring after 4 hours, let stand for 4 hours for defoaming, and obtain a homogeneous casting film solution;

[0028] (3) Apply the casting solution obtained in (2) on the surface of the polyester non-woven fabric and scrape it into a flat shape. The temperature of the scraping film is 200°C, and then enter it into a 45°C water tank to cool and solidify

[0029] (4) Ultrasonic extraction of the film obtained in step (3) with an anhydrous ethanol extractant with a purity of 99.7% for 24 hours, and after the extraction is completed, put it in a vacuum oven at 50°C to dry to obtain a high-density polyethylene / ethylene ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com