Organolithium compound, method for production of modified conjugated diene-based polymer using same, and modified conjugated diene-based polymer

A conjugated diene, organolithium technology, applied in the direction of lithium organic compounds, organic chemistry, rolling resistance optimization, etc., can solve problems such as insufficient effect, and achieve the effect of excellent affinity, good processability, and low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

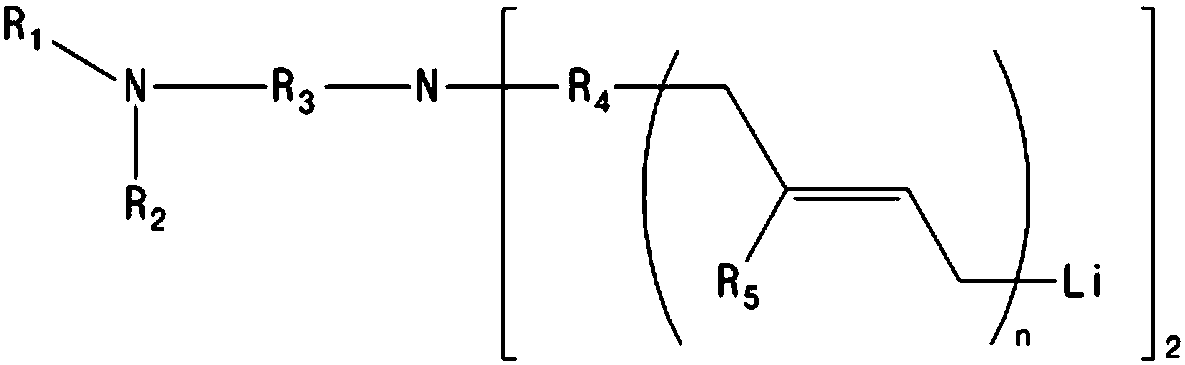

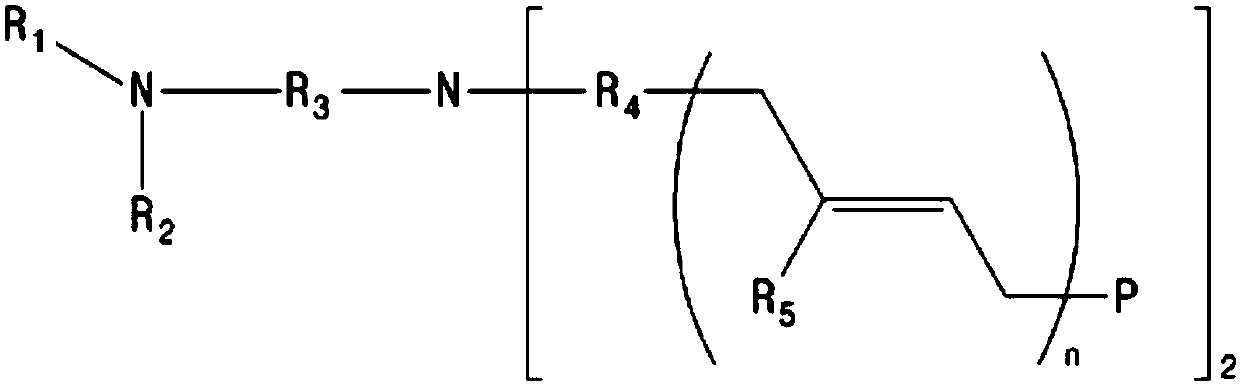

[0073] A production method according to one embodiment of the present invention includes polymerizing a conjugated diene-based monomer in a hydrocarbon solvent in the presence of an organolithium compound represented by the following formula 1, or making the conjugated diene-based monomer and a step of polymerizing an aromatic vinyl-based monomer (step A).

[0074] [Formula 1]

[0075]

[0076] In formula 1,

[0077] R 1 , R 2 and R 5 each independently being a monovalent hydrocarbon group having 1 to 10 carbon atoms,

[0078] R 3 and R 4 are each independently a divalent hydrocarbon group having 1 to 10 carbon atoms, and,

[0079] n is an integer of 1 to 5.

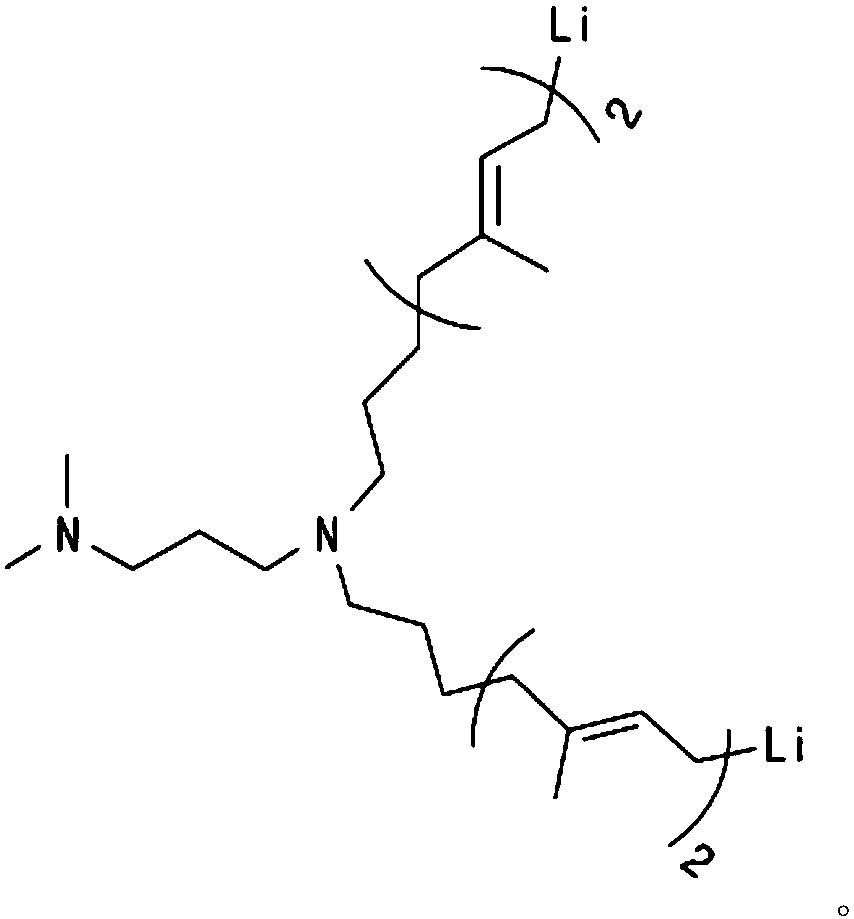

[0080] In particular, specific examples of the organolithium compound represented by Formula 1 may be the same as described above.

[0081] Step A is a step of preparing a living polymer, wherein a functional group derived from the organolithium compound represented by the above formula 1 is bonded to at leas...

Embodiment

[0125] 270 g of styrene, 710 g of 1,3-butadiene, 5000 g of n-hexane, and 1.3 g of 2,2-bis(2-oxolyl)propane as a polar additive were added to a 20 L high-pressure In the still reactor, the temperature inside the reactor was then raised to 40°C. When the temperature in the reactor reached 40° C., 0.4 mmol of the organolithium compound of Formula 2 prepared in Preparation Example was injected into the reactor, followed by an adiabatic heating reaction. After about 20 minutes, 20 g of 1,3-butadiene were added. After 5 minutes, 0.7 g of bis-(3-triethoxymethylsilylpropyl)-N-methylamine was injected, and the reaction was allowed to proceed for 15 minutes. Then, the polymerization reaction was terminated using ethanol, and 5 mL of 0.3% by weight of butylated benzyl alcohol (BHT) as an antioxidant dissolved in hexane was added thereto. The polymer thus obtained was poured into hot water heated with steam and stirred to remove the solvent, and then tumbled to remove the remaining solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com