Application of hemispherical Luneberg lens antenna

一种龙伯透镜天线、半球的技术,应用在通信领域,能够解决透镜性能影响、制作工艺难度高、产品一致性差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

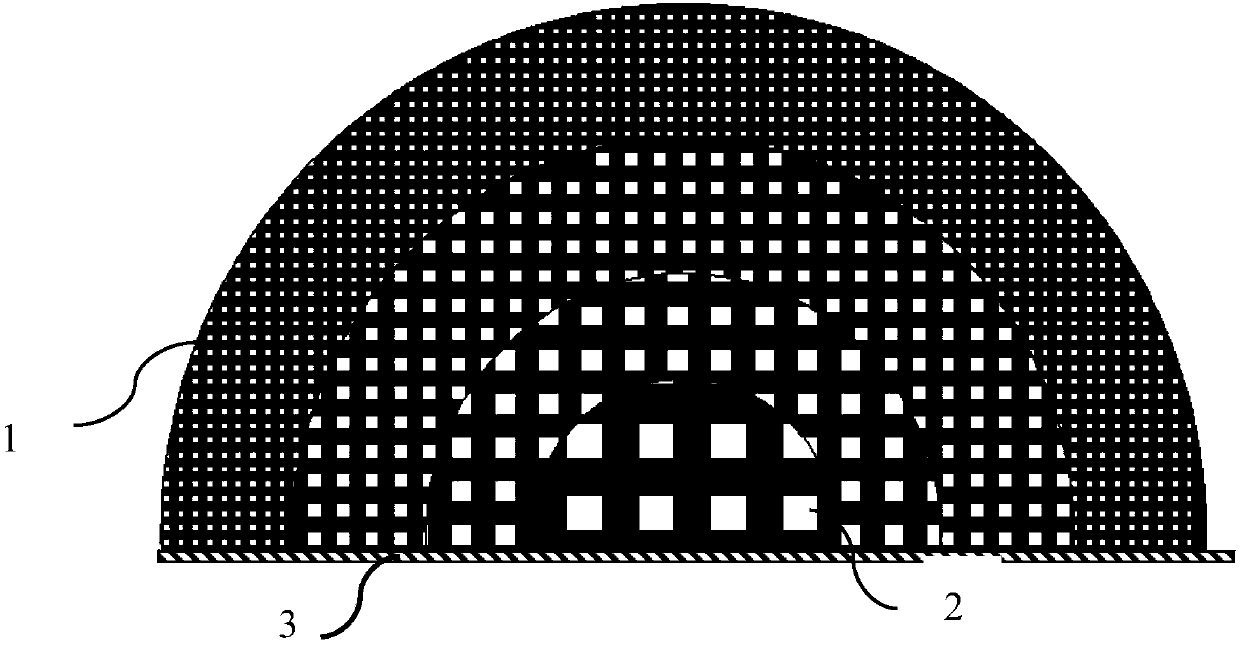

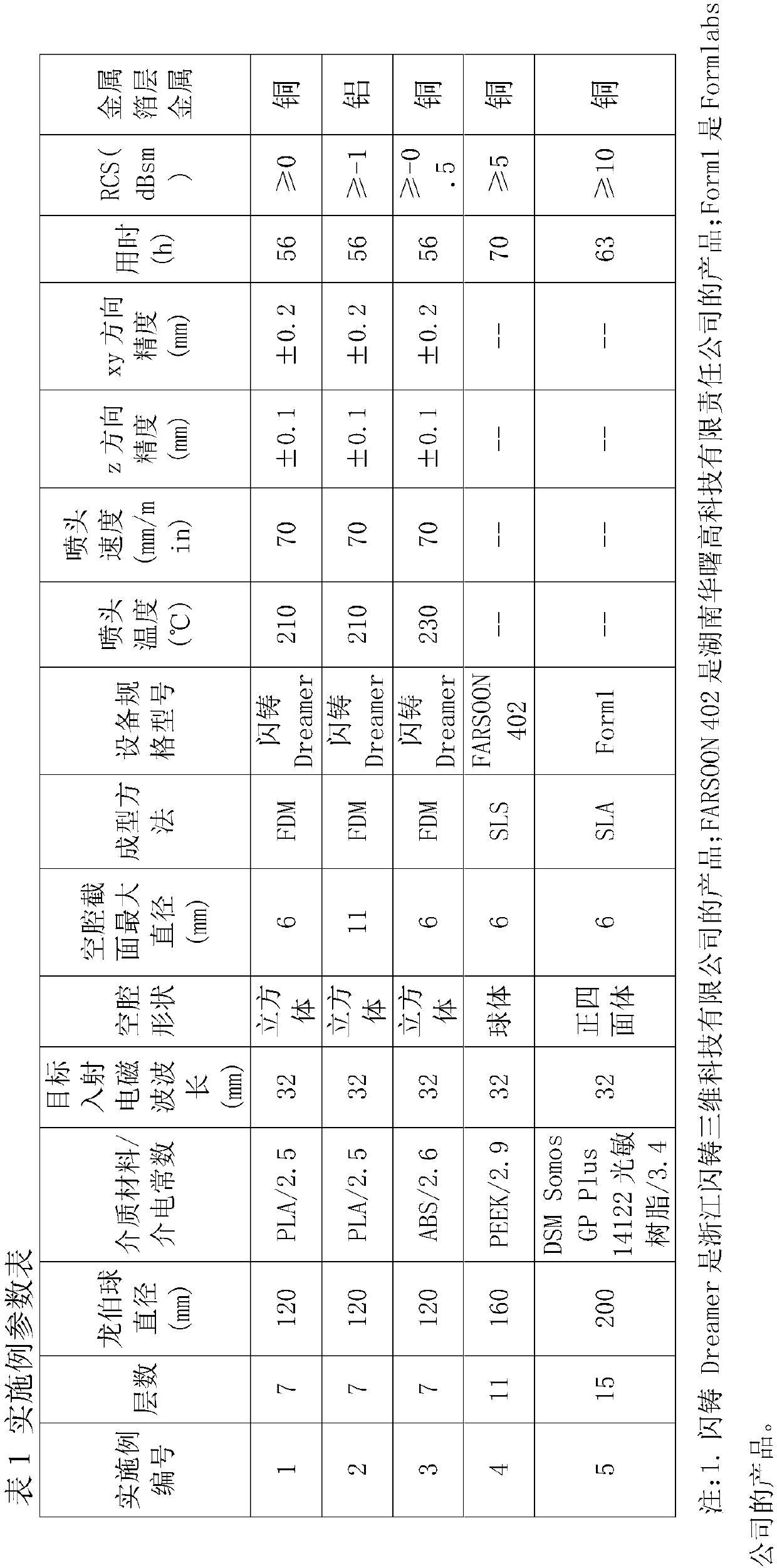

[0147] The hemispherical Lunberg lens antenna made in this embodiment is a hemisphere, in which cavities are distributed, the radius R of the sphere is 60mm, the target RCS value is greater than or equal to 0dBsm, the target incident electromagnetic wave is 9.4GHz, the wavelength is 32mm, and the cavity is A regular hexahedron with a side length of 3.5 mm and a metal foil layer thickness of 0.2 mm.

[0148] In this embodiment, PLA is selected as the material for making the hemispherical Lunberg lens antenna, and its dielectric constant is 2.5. Then use the formula ε i =2-(r i / R) 2 Calculate the dielectric constant of each concentric layer; then calculate the cavity volume fraction of each concentric layer according to the following formula: the average dielectric constant of each concentric layer=[the dielectric constant of this concentric layer material × (1-all in this concentric layer cavities in the concentric layer) + the dielectric constant of the cavity medium × the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com