Double crosslinking binder for silicon-based negative electrode material for lithium battery, silicon-based negative electrode material for lithium battery, preparation method, negative electrode of battery and lithium battery

A silicon-based negative electrode material, double cross-linking technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of unstable ester bonds, high energy consumption, battery capacity attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Still other embodiments of the present invention provide a method for preparing a silicon-based negative electrode material for a lithium battery described in the above embodiments, comprising the following steps:

[0033] Step 101: preparing polyacrylic acid in N,N-dimethylformamide solution with a concentration of 45-55 mg / ml;

[0034] Step 102: Prepare a N,N-dimethylformamide solution of hexamethylene diisocyanate at a concentration of 15-55 mg / ml;

[0035] Step 103: Weigh the silicon-based material and conductive carbon black, put them into the container together with the N,N-dimethylformamide solution of polyacrylic acid, stir and mix well, and then add the N,N, The N-dimethylformamide solution is continuously stirred to form a uniformly mixed slurry to obtain the silicon-based negative electrode material for lithium batteries.

[0036] In this preparation method, the polyacrylic acid and diisocyanate in the binder given in the above examples are first configured ...

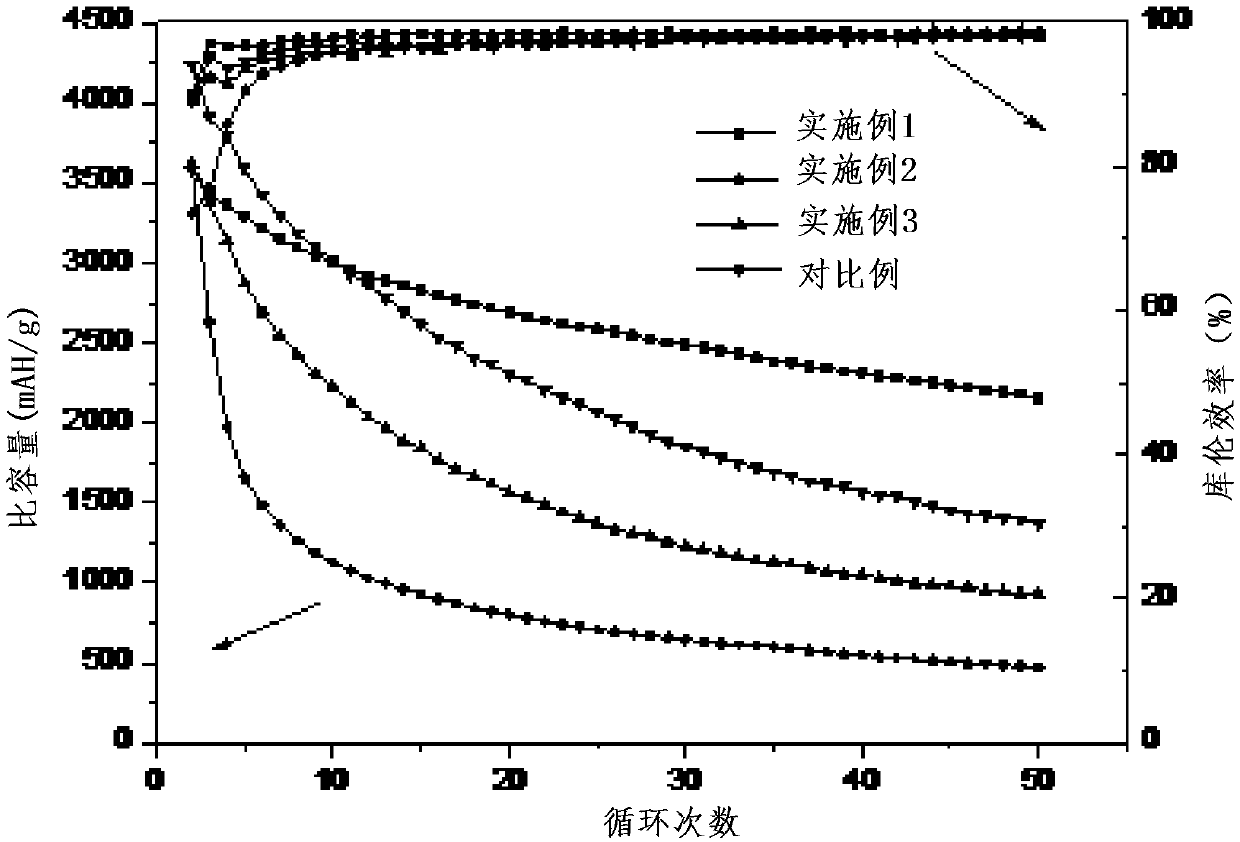

Embodiment 1

[0042] Prepare PAA / N,N-dimethylformamide solution (DMF) at a concentration of 50 mg / mL.

[0043] Prepare a hexamethylene diisocyanate (HDI) / N,N-dimethylformamide solution with a concentration of 50 mg / mL.

[0044] Weigh 18 mg of silicon powder 1-5 μm, 6 mg of Super-P conductive carbon black, and 120 μL of PAA / DMF into an agate mortar, stir well for 1 hour, then add HDI / DMF (6 μL, 2mol% vs acrylic acid) dropwise, continue Stir for 0.5h. Spread the uniformly mixed slurry evenly on the treated Cu foil (150mm*100mm*9μm), dry at room temperature for 2h, and then place it in a vacuum oven and dry at 60°C for 12h. Cut the dried pole piece into a 7mm square. After weighing and calculating the mass of the active material on a single pole piece, vacuum dry at 60°C for 2 hours. The dried pole piece was moved to a glove box, and a lithium piece was used as a counter electrode to assemble a 2032 button cell. The electrolyte is 1.3M lithium hexafluorophosphate (Aladdin, LiPF 6 ) is an ...

Embodiment 2

[0046] Prepare PAA / N,N-dimethylformamide solution (DMF) at a concentration of 50 mg / mL.

[0047] Prepare a hexamethylene diisocyanate (HDI) / N,N-dimethylformamide solution with a concentration of 50 mg / mL.

[0048] Weigh 18 mg of silicon powder 1-5 μm, 6 mg of Super-P conductive carbon black, and 120 μL of PAA / DMF into an agate mortar, stir and mix well for 1 hour, then add HDI / DMF (15 μL, 5mol% vs acrylic acid base) dropwise, continue Stir for 0.5h. Spread the uniformly mixed slurry evenly on the treated Cu foil (150mm*100mm*9μm), dry at room temperature for 2h, then place in a vacuum oven, and dry at 60°C for 12h. Cut the dried pole piece into a 7mm square. After weighing and calculating the mass of the active material on a single pole piece, vacuum dry at 60°C for 2 hours. The dried pole piece was moved to a glove box, and a lithium piece was used as a counter electrode to assemble a 2032 button cell. The electrolyte is 1.3M lithium hexafluorophosphate (Aladdin, LiPF 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com