A Design Method of High Flatness Medium-Strength Magnetic Field Measurement Coil

A technology for measuring coils and design methods, applied in measuring devices, measuring magnetic variables, instruments, etc., can solve problems such as low accuracy, inaccurate Hall probe AC conversion coefficients, and cumbersome calibration of coil constant values, and achieve fast response speed. , Simple structure, easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below with reference to the drawings and embodiments.

[0047] The present invention provides a method for designing a high-flatness medium-strong magnetic field measuring coil, and the specific steps are as follows:

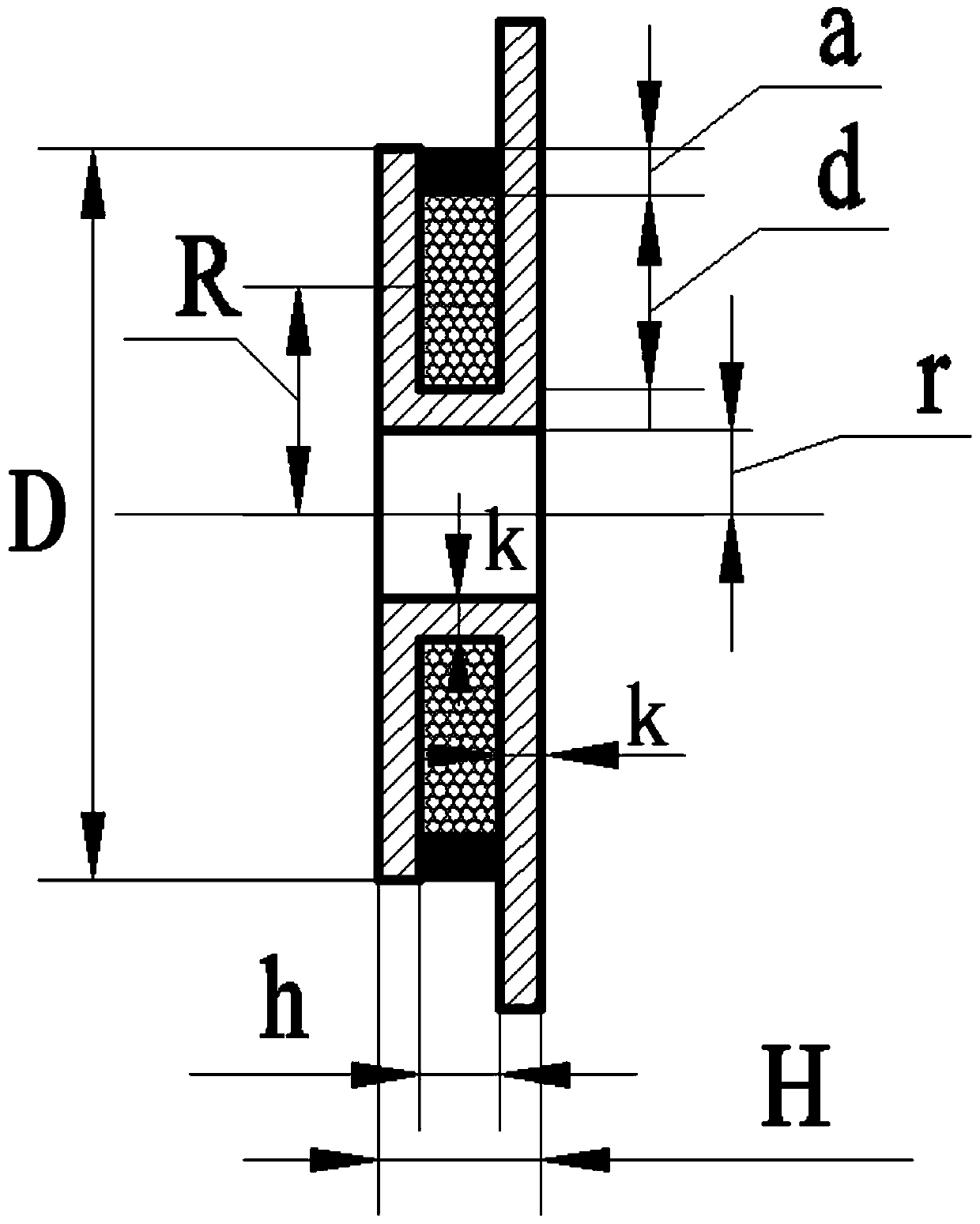

[0048] The first step, see attached figure 1 Select the skeleton of the measuring coil. The skeleton is composed of three sections of cylindrical structures with different diameters. The middle section has the smallest diameter, thereby forming an annular cavity between the cylindrical structures at both ends. The annular cavity is the installation slot for the measuring coil. , The end surface of the cylindrical structure at one end is machined with positioning holes and radial lead grooves communicating with the positioning holes, and the frame is made of non-magnetic and hard non-metallic materials, such as epoxy polyester, Polysulfone or quartz;

[0049] The measuring coil is a copper wire with insulating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com