Composite material pile-anchor supporting device

A technology of composite materials and supporting devices, applied in sheet pile walls, construction, excavation, etc., can solve the problems of accelerating construction progress, wasting environmental pollution, and not being able to reuse, so as to reduce stress concentration, reduce operation and maintenance costs, and reduce production costs. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

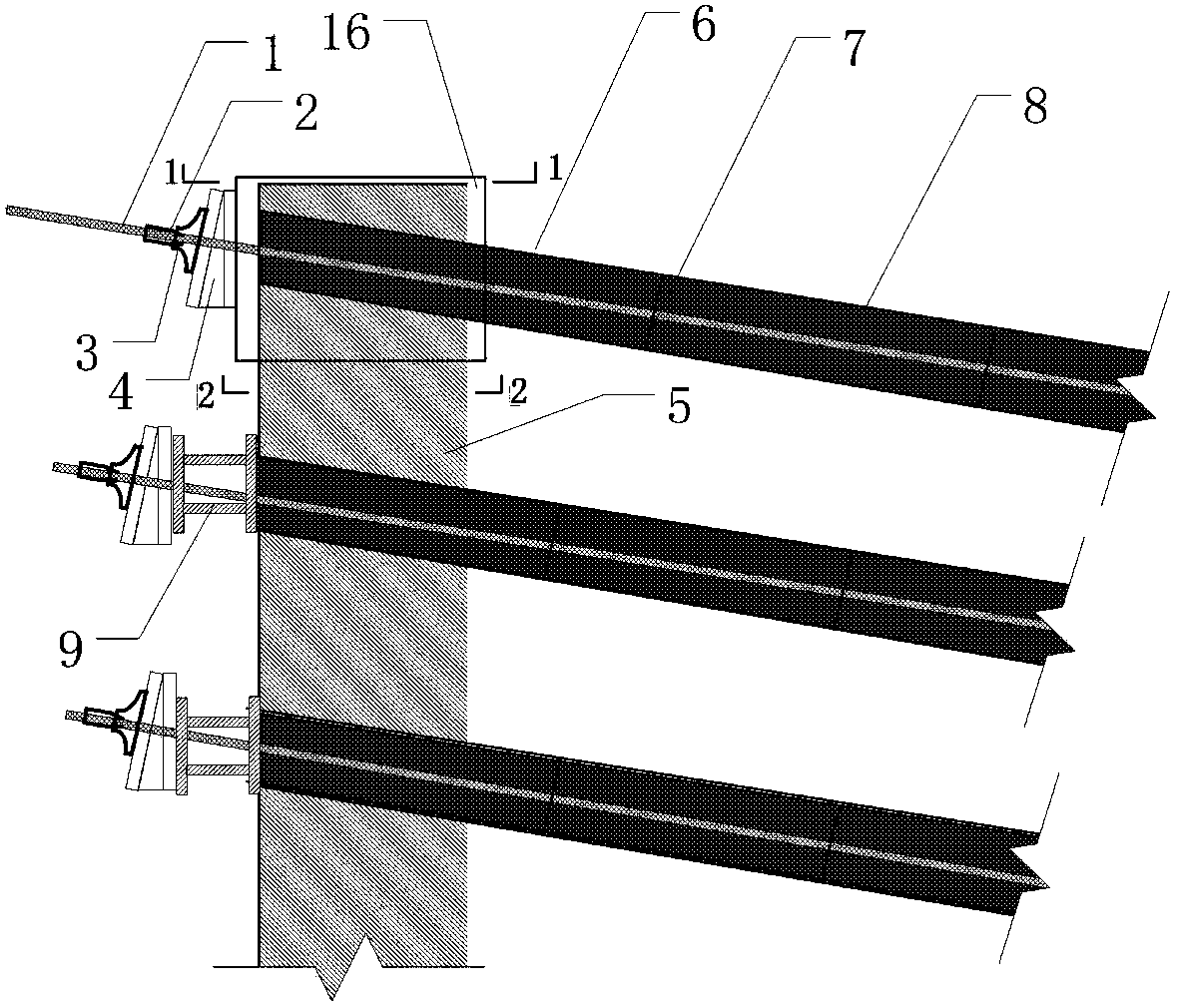

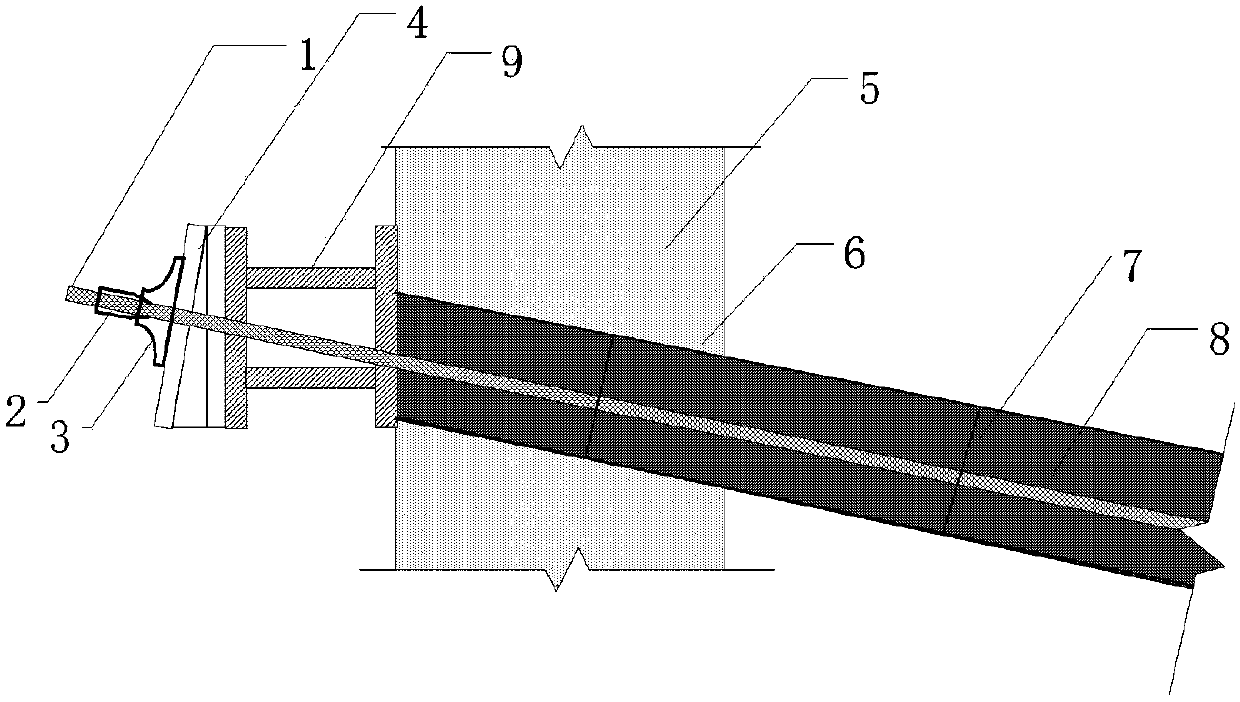

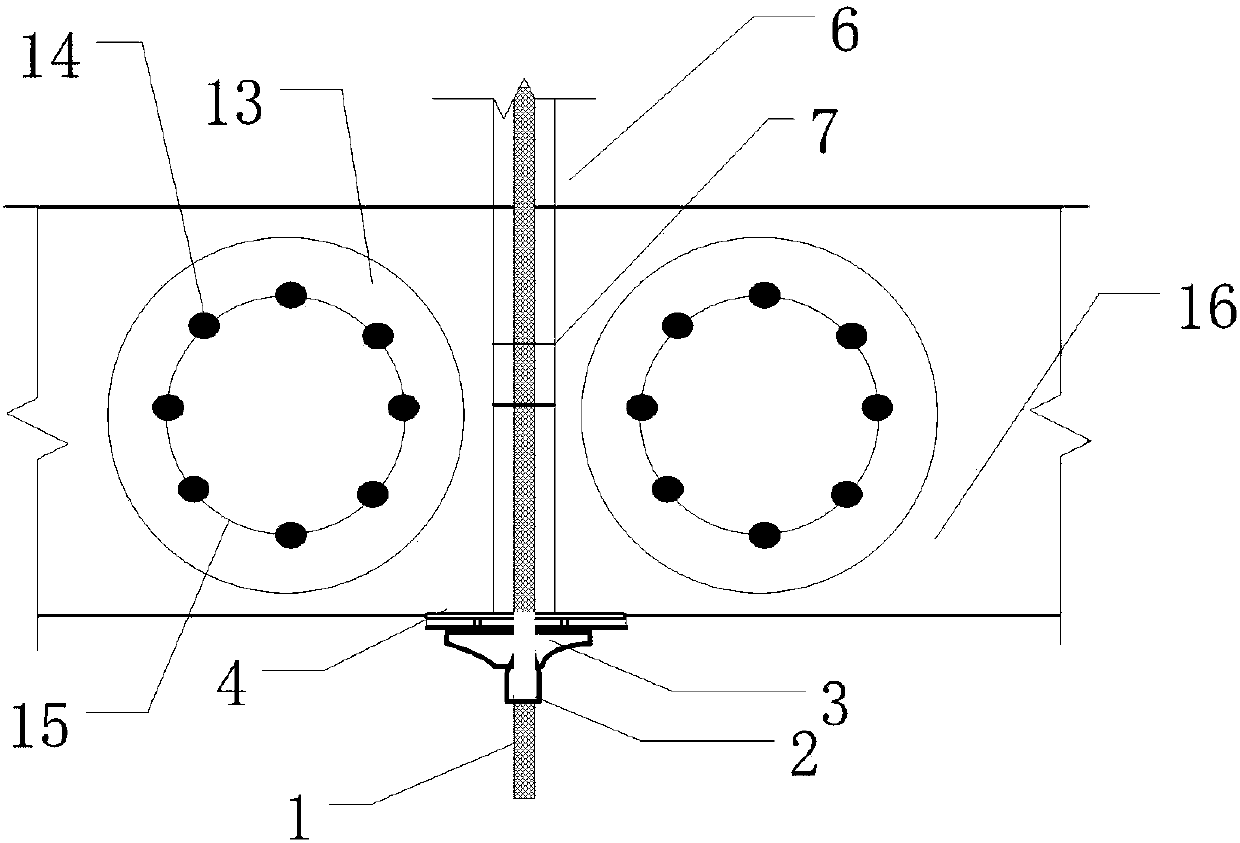

[0028] The main structure of the composite material pile-anchor support device described in this embodiment includes an anchor rod body 1, a fastening nut 2, a stress diffusion plate 3, a lattice steel pad 4, soil between piles 5, an anchor hole 6, centering Bracket 7, grouting body 8, double web type composite material waist beam 9, cast-in-place pile 13, main reinforcement 14, spiral stirrup 15, crown beam 16, inner sleeve 17, bolt 18 and steel gasket 19; anchor rod body 1 is a glass fiber reinforced polymer (GFRP) full-threaded solid structure; the fastening nut 2 and the stress diffusion disc 3 are made of GFRP material, and the size is matched with the anchor rod body 1, and they are connected to the anchor rod body 1 by threaded connection , the fastening nut 2 is hexagonal, the stress diffusion plate 3 is disc-shaped, and the inner end of the fastening nut 2 is engaged with the stress diffusion plate 3, which can provide sufficient anchoring force; the latticed steel pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com