A Method for Electrochemical Repair of Hydrogen-terminated Diamond Surfaces for Ion Sensors

A technology of ion sensor and repair method, which is applied in the field of semiconductor electrochemical applications, can solve problems such as surface resistance increase, damage, and sensor sensitivity reduction, and achieve the effect of consistent processing methods and widening applications and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

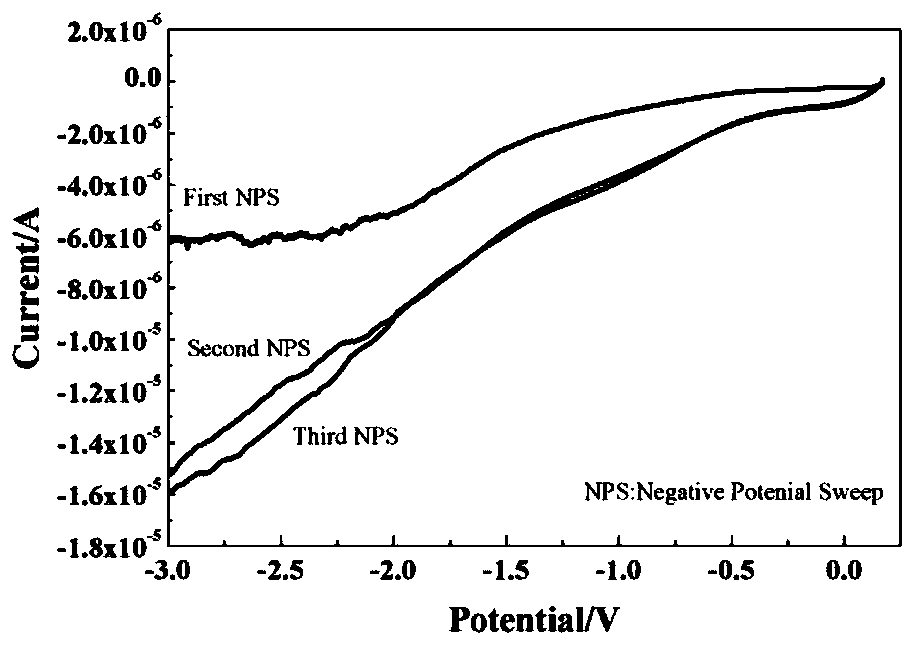

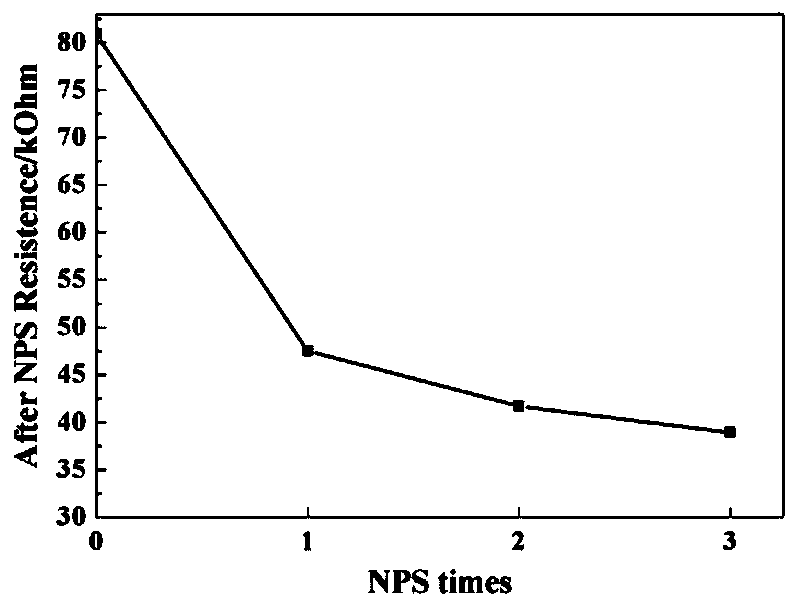

[0041] (1) Weigh 4.9g of sulfuric acid and 1L of deionized water to prepare 0.05M H 2 SO 4 solution to ensure that the solution pH ≈ 1; (2) connect the double wires of the diamond electrode structure treated by the damage reaction after ultrasonic cleaning with deionized water for 5-15mins to the working electrode of the electrolytic cell, and use a Pt electrode as the counter electrode; (3) connect the The prepared solution was poured into the electrolytic cell, and the negative potential linear scanning mode was turned on, and the voltage was scanned once from 0 to -3V; (4) After the scanning was completed, it was left to stand for 5 minutes to wait for the solution to be uniform, and the potential of the reference electrode returned to the initial potential and Once stable, scan from 0 to -3V again; (5) After scanning three times in this method, place the diamond electrode in deionized water for ultrasonic cleaning for 5-15mins, and take out the diamond. Ventilate and dry ...

specific Embodiment approach 2

[0043] (1) Weigh 0.49g sulfuric acid and 1L deionized water to prepare 0.005M H 2 SO 4 solution to ensure that the solution pH ≈ 2; (2) connect the double wires of the diamond electrode structure treated by the damage reaction after ultrasonic cleaning with deionized water for 5-15mins to the working electrode of the electrolytic cell, and use a Pt electrode as the counter electrode; (3) connect the The prepared solution was poured into the electrolytic cell, and the negative potential linear scanning mode was turned on, and the voltage was scanned once from 0 to -3V; (4) After the scanning was completed, it was left to stand for 5 minutes to wait for the solution to be uniform, and the potential of the reference electrode returned to the initial potential and Once stable, scan from 0 to -3V again; (5) After scanning three times in this method, place the diamond electrode in deionized water for ultrasonic cleaning for 5-15mins, and take out the diamond. Ventilate and dry at 8...

specific Embodiment approach 3

[0045] (1) Weigh 3.65g of hydrochloric acid and 1L of deionized water to prepare 0.1M HCl solution to ensure that the solution PH≈1; (2) Use deionized water to ultrasonically clean the damaged reaction-treated double wire with diamond electrode structure for 5-15mins Both are connected to the working electrode of the electrolytic cell, and the counter electrode is a Pt electrode; (3) pour the prepared solution into the electrolytic cell, and turn on the negative potential linear scanning mode for it, and scan the voltage once from 0 to -3V; (4) scan After the completion, let it stand for 5mins to wait for the solution to be uniform, the potential of the reference electrode returns to the initial potential and reaches stability, and then scans from 0 to -3V again; (5) After scanning three times in this method, place the diamond electrode in deionized water for ultrasonic cleaning 5-15mins, and take out the diamond, its surface moisture is ventilated and dried in a ventilated dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com