Process for controlling melting speed of large slab electric slag furnace

An electroslag furnace and melting speed technology, applied in the field of metallurgy, can solve problems such as segregation, porosity increase, and metal molten pool deepening, etc., to achieve the effects of reducing production costs, reducing losses, and avoiding flaw detection failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

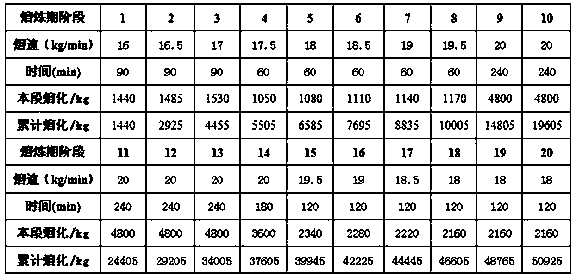

[0018] For a 50t-level slab electroslag furnace in a steel company, the process includes melting rate process design, offline simulation calculation, and process intervention control. The specific methods are as follows:

[0019] 1) The melting rate process design adopts the three-stage formula of "initial melting rate-maintaining melting rate-feeding melting rate".

[0020] The "initial melting rate" is 16kg / min. In the stage of "initial melting rate-maintaining melting rate", the melting rate increases gradually. The increase of melting rate is controlled by 0.5kg / min. The consumable electrode melts 1 / 5 of the total weight When (that is, 10 tons) to maintain the melting rate, the "maintaining melting rate" is 20kg / min.

[0021] In the stage of "maintaining the melting speed-feeding and shrinking the melting speed", the melting speed will decrease gradually. When the remaining weight of the consumable electrode is 1 / 4 of the total weight, it will start to decrease, and the de...

Embodiment 2

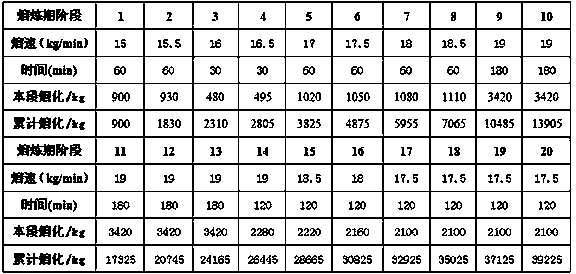

[0028] For a 45t-level slab electroslag furnace in a steel company, the process includes melting rate process design, offline simulation calculation, and process intervention control. The specific methods are as follows:

[0029] 1) The melting rate process design adopts the three-stage formula of "initial melting rate-maintaining melting rate-feeding melting rate".

[0030] The "initial melting rate" is 16kg / min. In the stage of "initial melting rate-maintaining melting rate", the melting rate increases gradually. The increase of melting rate is controlled by 0.5kg / min. The consumable electrode melts 1 / 5 of the total weight When it reaches the maintenance melting rate (ie 9 tons), the "maintenance melting rate" is 20kg / min.

[0031] In the stage of "maintaining the melting speed-feeding and shrinking the melting speed", the melting speed will decrease gradually. When the remaining weight of the consumable electrode is 1 / 3 of the total weight, it will start to decrease, and th...

Embodiment 3

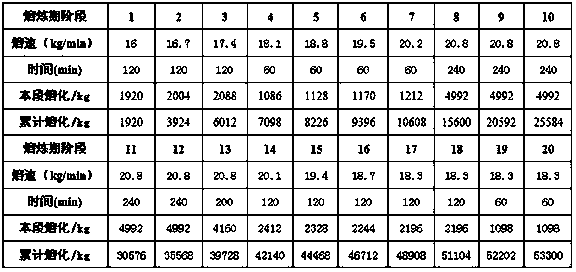

[0038] For a 35t-level slab electroslag furnace in a steel company, the process includes melting rate process design, offline simulation calculation, and process intervention control. The specific methods are as follows:

[0039] 1) The melting rate process design adopts the three-stage formula of "initial melting rate-maintaining melting rate-feeding melting rate".

[0040] The "initial melting rate" is 15kg / min. In the stage of "initial melting rate-maintaining melting rate", the melting rate increases gradually. The increase of melting rate is controlled by 0.5kg / min. The consumable electrode melts 1 / 5 of the total weight When (that is, 7 tons) to maintain the melting rate, the "maintaining melting rate" is 19kg / min.

[0041] In the stage of "maintaining melting speed-feeding and shrinking melting speed", the melting speed decreases, and the remaining weight of the consumable electrode is 1 / 4 of the total weight, and the decline of melting speed is controlled by 0.5kg / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com