Superhigh-temperature aerobic fermentation microbial agent prepared from municipal sludge and preparation method of superhigh-temperature aerobic fermentation microbial agent

A technology for municipal sludge and aerobic fermentation, applied in microorganism-based methods, biochemical equipment and methods, sewage/sludge fertilizers, etc. and other problems, to achieve the effect of improving the survival rate and preservation period, protecting and improving the ecological environment, and solving the difficulties of fermentation production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 produces Calditerricolasatsumensis ultra-high temperature aerobic fermentation bacterial agent

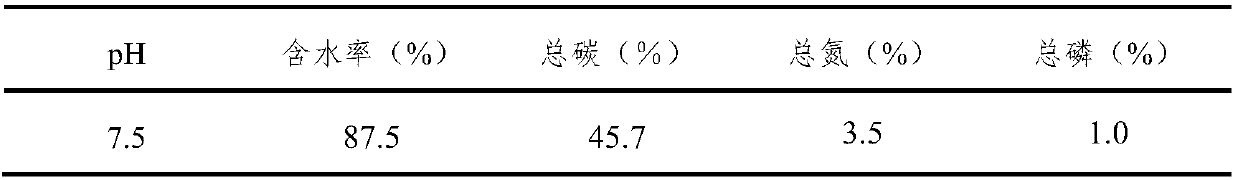

[0023] (1) Municipal sludge samples

[0024] The thickened sludge from a sewage treatment plant in Beijing was taken, and the basic properties of the sludge are shown in Table 1.

[0025] Table 1. Basic properties of the sludge tested

[0026]

[0027] (2) Sludge Fermentation Medium Configuration

[0028] Add water to adjust the solid content of the sludge to 2%, add 0.2% foam enemy, 1g / L yeast powder, 0.5g / L ammonium chloride, 0.3g / L sucrose, 0.2g / L soluble starch, 0.3g / L phosphoric acid Potassium dihydrogen, adjust the pH to 7.0, add 50g / L biochar / wheat bran (w / w=2 / 1) composite carrier, stir evenly, sterilize at 100°C for 45 minutes, cool to 70-80°C for later use.

[0029] (3) Shake flask culture Pick colonies from the well-preserved Calditerricolasatsumensis FAFU012 plate medium, inoculate into a 300mL Erlenmeyer flask containing 100mL CYS liquid medium...

Embodiment 2

[0038] Embodiment 2 produces Calditerricolayamamurae ultra-high temperature aerobic fermentation bacterial agent

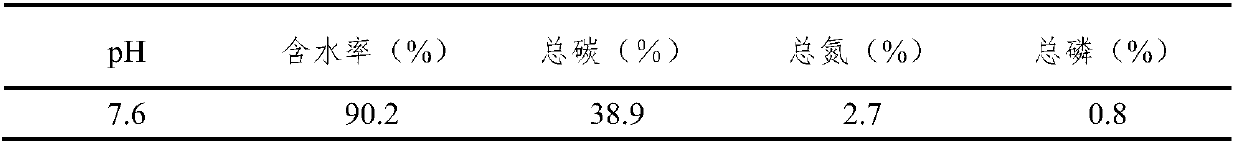

[0039] (1) Municipal sludge samples

[0040]The thickened sludge in Zhengzhou City, Henan Province was taken, and the basic properties of the sludge are shown in Table 2.

[0041] Table 2 Basic properties of the tested sludge

[0042]

[0043] (2) Sludge Fermentation Medium Configuration

[0044] Add water to adjust the solid content of the sludge to 3%, add 0.2% foam enemy, 1.5g / L yeast powder, 1.0g / L ammonium chloride, 0.5g / L sucrose, 0.5g / L soluble starch, 0.5g / L Potassium dihydrogen phosphate, adjust the pH to 7.0, add 80g / L biochar / wheat bran (w / w=1.5 / 1) composite carrier, stir evenly, sterilize at 100°C for 45 minutes, cool to 70-80°C for later use.

[0045] (3) Shake flask culture Pick colonies from the normal preserved Calditerricolayamamurae UTM801 plate medium, inoculate into a 300mL Erlenmeyer flask containing 100mL CYS liquid medium, and culture ...

Embodiment 3

[0054] Embodiment 3 produces Thermusthermophilus ultra-high temperature aerobic fermentation bacterial agent

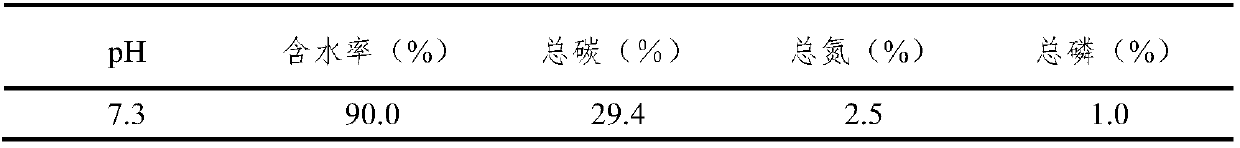

[0055] (1) Municipal sludge samples

[0056] Take the thickened sludge from a sewage treatment plant in Fuzhou City, Fujian Province. The basic properties of the sludge are shown in Table 3.

[0057] Table 3. Basic properties of the tested sludge

[0058]

[0059] (2) Sludge Fermentation Medium Configuration

[0060] Add water to adjust the solid content of the sludge to 3%, add 0.2% foam enemy, 1.5g / L yeast powder, 0.5g / L ammonium chloride, 0.5g / L sucrose, 0.5g / L soluble starch, 1g / L phosphoric acid Potassium dihydrogen, adjust the pH to 7.0, add 100g / L biochar / wheat bran (1.5 / 1) composite carrier, stir evenly, sterilize at 100°C for 45 minutes, cool to 70-80°C for later use.

[0061] (3) Shake flask culture Pick colonies from the well-preserved Thermusthermophilus HB8 plate medium, inoculate into a 300mL Erlenmeyer flask containing 100mL CYS liquid medium, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com