Auxiliary for improving the quality of regenerated waste lubricating oil and its preparation method

A waste lubricating oil and finished product technology, applied in the direction of lubricating composition, etc., can solve the problems of inability to realize effective regeneration of waste lubricating oil, unreasonable resource conversion and utilization, waste of lubricating oil resources, etc., achieve good oxidation stability and improve processing Capacity and safety production coefficient, the effect of avoiding serious waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

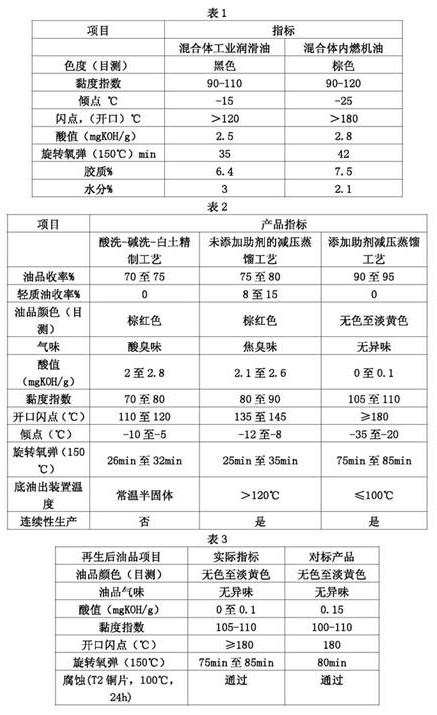

Image

Examples

Embodiment 1

[0020] Embodiment 1, the auxiliary raw material for improving the quality of the finished product after the regeneration of waste lubricating oil includes 80% to 85% of organic alkalis, 1% to 5% of inorganic alkalis, and 5% to 10% of caking Dispersant, 1% to 5% of adsorbent and the balance of co-solvent.

Embodiment 2

[0021] Embodiment 2, the auxiliary agent for improving the finished product quality after the regeneration of waste lubricating oil comprises 80% or 85% of organic bases, 1% or to 5% of inorganic bases, 5% or 10% of caking Dispersant, 1% or 5% adsorbent and the balance of co-solvent.

[0022] Organic bases and inorganic bases are blended, bonded and interacted to effectively reduce the content of unsaturated substances such as olefins and alkynes in waste engine oil. It can neutralize acidic substances in waste engine oil, such as a small amount of mercaptans, aldehydes, ketones and other acidic substances in waste engine oil, so that the acid value of the finished base oil can be effectively reduced, and a small amount of adsorbent can be added to effectively absorb colloids in waste engine oil , asphaltene and other organic impurities, reduce the oil cracking reaction caused by colloids and asphaltene in waste engine oil during processing, and eliminate the production of lig...

Embodiment 3

[0024] Embodiment 3, as the optimization of embodiment 1 and embodiment 2, organic bases are quaternary ammonium bases; or / and, inorganic bases are inorganic sodium alkali salts or inorganic potassium alkali salts; or / and, bonding dispersion The agent is modified bentonite or activated bentonite; or / and, the adsorbent is activated carbon or activated clay; or / and, the cosolvent is carbonamide. The solubility and alkali value of quaternary ammonium base are the best, which is most suitable for the present invention; modified bentonite and activated bentonite have large pore size, and fine particles are easy to suspend; activated carbon and activated clay both have large pore size and fine particle characteristics, and the adsorption effect Good; carbonamides have good hydrophilicity and lipophilicity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com