PEN modified polyester resin for epoxy polyester mixed powder paint and preparation method thereof

A technology of epoxy polyester and powder coatings, which is applied in the direction of powder coatings, polyester coatings, epoxy resin coatings, etc., which can solve the problems of complex production process, limited development, high cost, etc., and achieve reduced production costs and excellent leveling , high storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

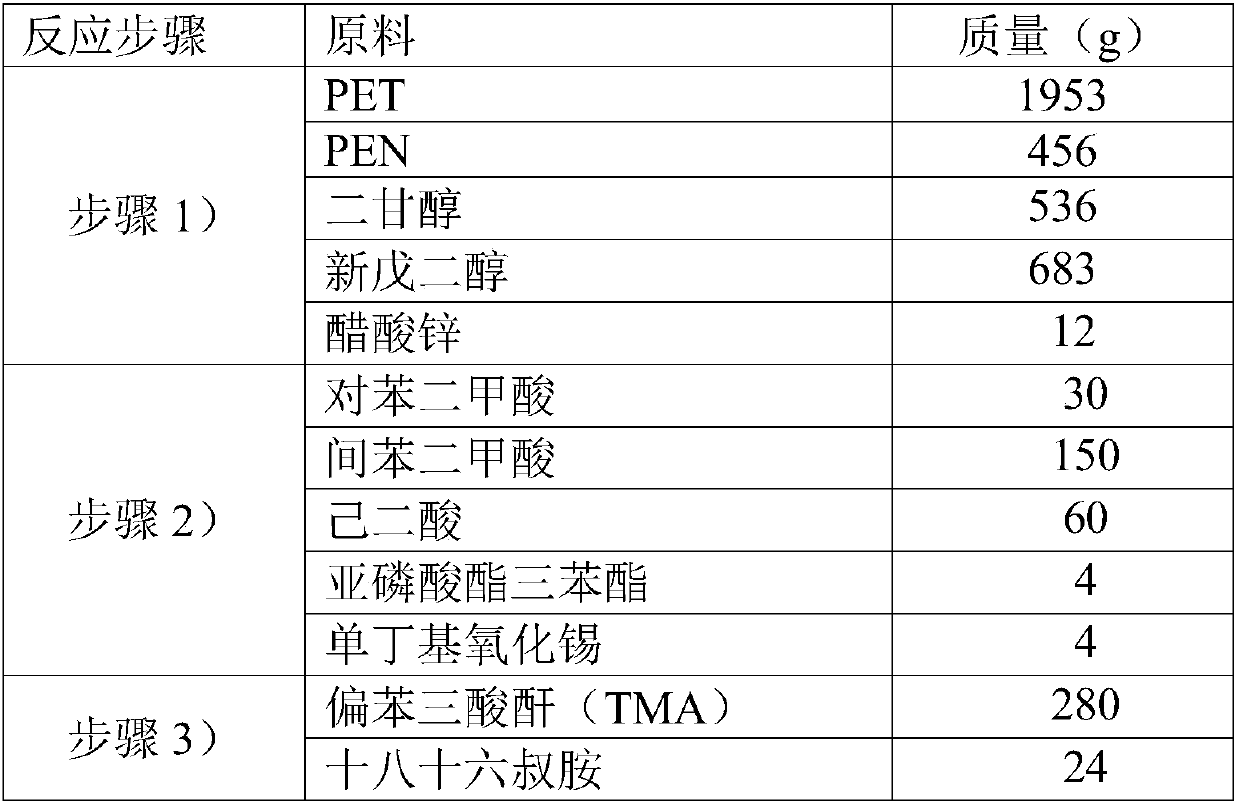

Method used

Image

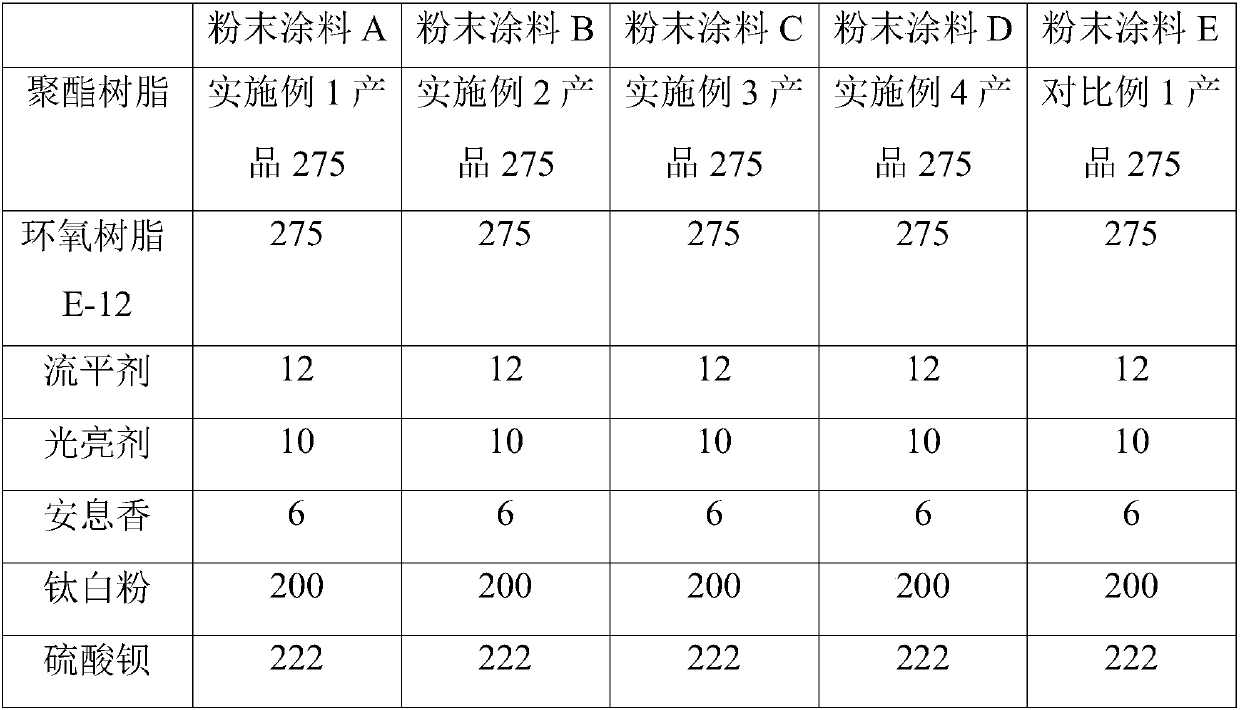

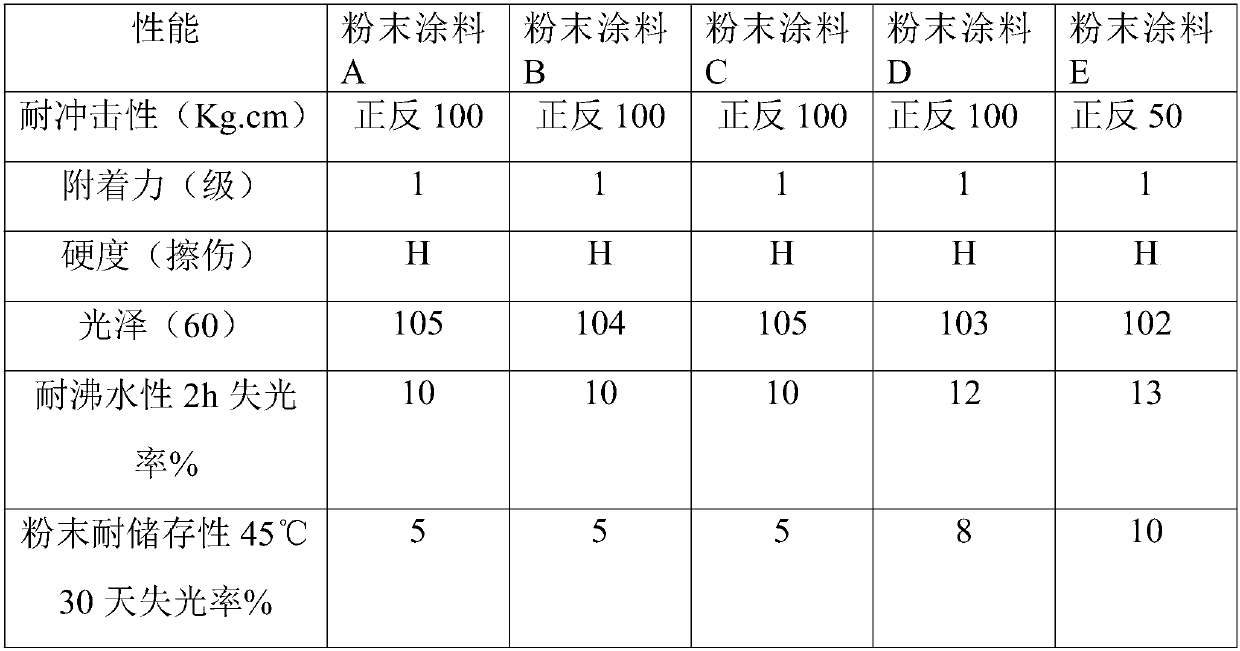

Examples

Embodiment 1

[0042] 1) 1850g of PET and 620g of PEN after cleaning, impurity removal and crushing are mixed with 850g of 2-methyl-1,3-propanediol in the presence of 4.8g of alcoholysis catalyst zinc acetate at a pressure of 1.2MPa and a temperature of 235-240 ℃ alcoholysis reaction for 3h;

[0043] 2) The alcoholysis is completed, the pressure in the reactor is ≤-0.095MPa, the temperature is 180-240°C, and the free polyols are removed by distillation (the polyols obtained after separation are separated by rectification, and the ethylene glycol in them is directly sold as a by-product , other polyols except ethylene glycol can be applied mechanically), add neopentyl glycol 50g, terephthalic acid 260g, isophthalic acid 100g, adipic acid 60g, stabilizer ( Triphenyl phosphite) 3.3g, carry out esterification and / or transesterification in the presence of monobutyl tin oxide 3.3g;

[0044] 3) When the degree of esterification reaches more than 96% (generally, it is observed that the temperature ...

Embodiment 2

[0048] Step 1) is identical with embodiment 1;

[0049] 2) After the alcoholysis is finished, directly add neopentyl glycol 50g, terephthalic acid 1200g, isophthalic acid 170g, adipic acid 90g, stabilizer (triphenyl phosphite) 3.3g in the reactor, Carry out esterification and / or transesterification in the presence of monobutyltin oxide 3.3g;

[0050] 3) When the degree of esterification reaches more than 96% (generally, it is observed that the temperature at the top of the reactivity tower drops below 50°C, the esterification water in the reactor is basically exhausted, and the degree of esterification reaches more than 96%), when the acid value is When the test viscosity is 3000±500mPa.s at 28±2mgKOH / g and 150°C, the transesterification and esterification reactions are over;

[0051] Carry out reduced pressure polymerization reaction, the described reduced pressure polymerization reaction conditions are: the pressure inside the reactor ≤ -0.09MPa, temperature 220 ~ 250 ° C; ...

Embodiment 3

[0054] 1) 1850g of PET and 620g of PEN after washing, removing impurities and crushing, react with 1270g of neopentyl glycol in the presence of 8g of alcoholysis catalyst zinc acetate at a pressure of 8MPa and a temperature of 235-240°C for 1h;

[0055] 2) The alcoholysis is completed, the pressure in the reactor is ≤-0.09MPa, the temperature is 180-240°C, the free polyols are removed by distillation, and 940g of terephthalic acid, 230g of isophthalic acid, Adipic acid 90g, stabilizer (triphenyl phosphite) 4g, carry out esterification and / or transesterification in the presence of monobutyl tin oxide 4g;

[0056] 3) When the degree of esterification reaches more than 96% (generally, it is observed that the temperature at the top of the reactivity tower drops below 50°C, the esterification water in the reactor is basically exhausted, and the degree of esterification reaches more than 96%), when the acid value is When the test viscosity is 3000±500mPa.s at 28±2mgKOH / g and 150°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com