Wind-proof pull rod for crane

A crane and tie rod technology, applied in the field of cranes and port cranes, can solve the problems of inconvenient insertion, complicated operation, damage to components, etc., and achieve the effects of avoiding rigid damage, small contact stress and large force area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

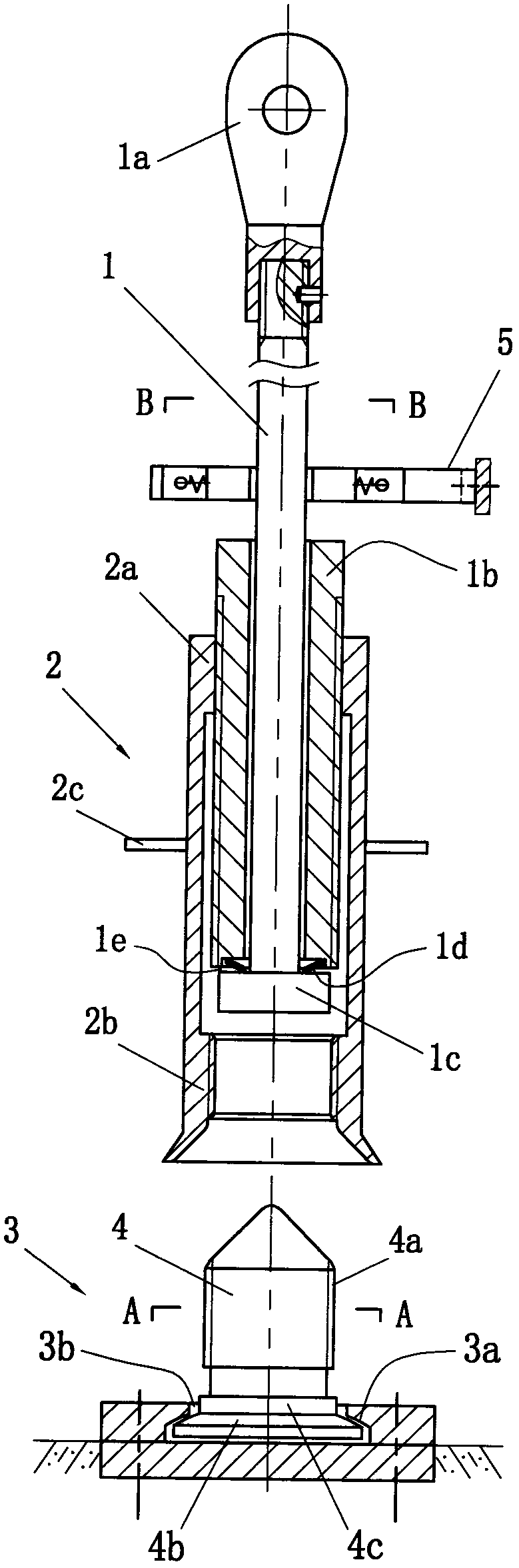

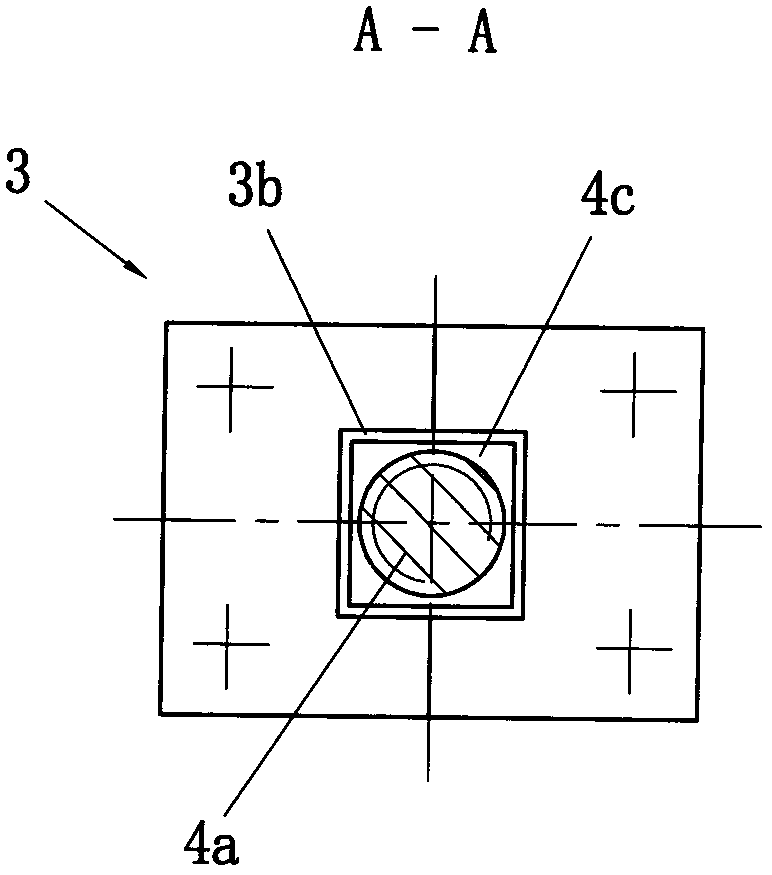

[0029] Example 1, see Figure 1 to Figure 4 .

[0030] The present invention includes a tie rod part 1 and a fixing seat 3. The upper end of the tie rod part 1 is provided with a first connecting part 1a connected with the components on the crane. And it is fixed with pins; the first connecting part 1a has various implementation structures.

[0031]A sleeve 1b is arranged on the lower section of the tie rod 1, and the sleeve 1b is supported by the boss 1c at the lower end of the tie rod 1. Under the action of an external force, the sleeve 1b can rise along the lower section of the tie rod 1 and freely fall after rising; An elastic part 1d is arranged on the joint surface of the lower end of the sleeve 1b and the lower end boss 1c of the tie rod part 1, and the elastic part 1d is positioned on the tie rod part 1, and the combination of the lower end surface of the sleeve 1b and the lower end boss 1c of the tie rod part 1 There is a gap 1e between the surfaces for the elastic ...

Embodiment 2

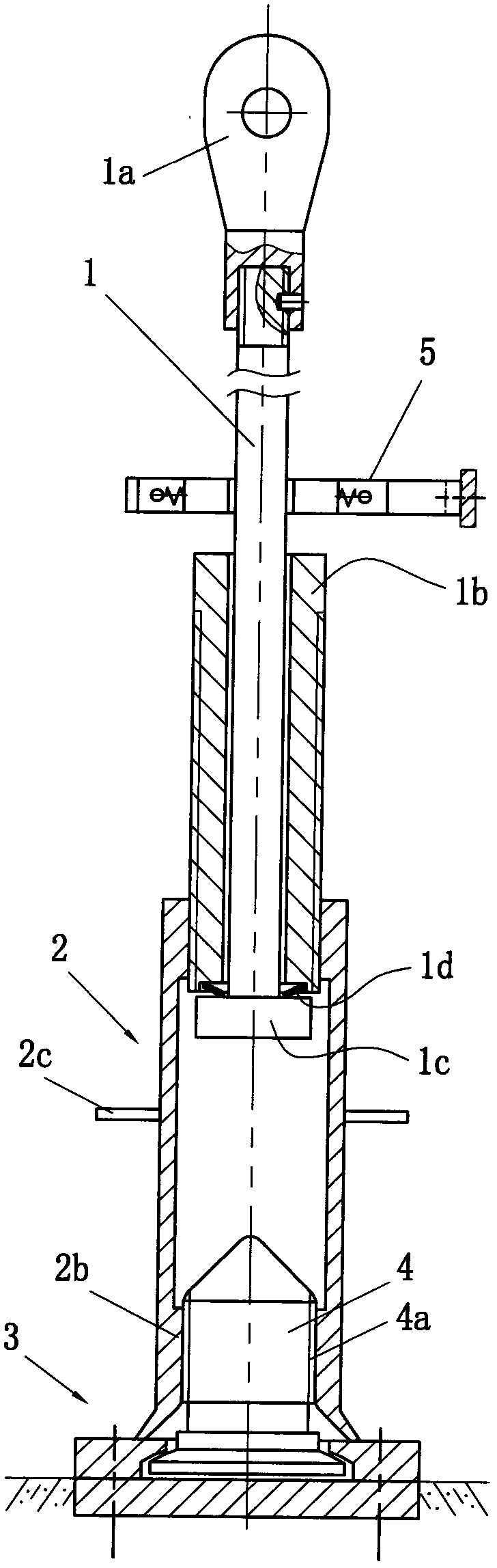

[0039] Example 2, see Figure 5 .

[0040] Including the rod part 1 and the fixing seat 3, the upper end of the rod part 1 is provided with the first connecting part 1a connected with the components on the crane; The pin is fixed; the first connecting part 1a has various implementation structures.

[0041] A sleeve 1b is arranged on the lower section of the tie rod 1, and the sleeve 1b is supported by the boss 1c at the lower end of the tie rod 1. Under the action of an external force, the sleeve 1b can rise along the lower section of the tie rod 1 and freely fall after rising; An elastic part 1d is arranged on the joint surface of the lower end of the sleeve 1b and the lower end boss 1c of the tie rod part 1, and the elastic part 1d is positioned on the tie rod part 1, and the combination of the lower end surface of the sleeve 1b and the lower end boss 1c of the tie rod part 1 There is a gap 1e between the surfaces for the elastic part 1d to be compressed and deformed to av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com