Method for implementing the middle connection tensioning of cables and device thereof

A tensioning device and technology of steel strands, which are applied in the processing of building materials, construction, building construction, etc., can solve the problems of broken steel strands, insufficient tensioning construction space, and prestressing failure compensation. To achieve the effect of stable working conditions, low construction technical risk and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

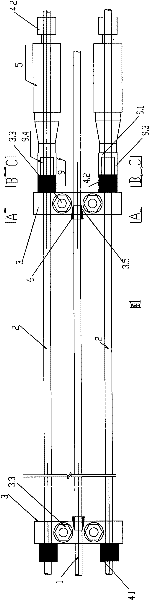

[0041] Such as figure 1 As shown, it is an intermediate tensioned steel strand to measure the tension of the steel strand or an intermediate tensioned prestressed anchor.

[0042] Two tool steel strands 2 are arranged on both sides of the steel strand 1, and the two ends of the two tool steel strands 2 pass the open flat anchor 3 to clamp the tool steel strand 2 and the steel strand 1 as a whole. One end of the tool steel strand is provided with a single-hole anchor 4.1, and the single-hole anchor 4.1 is in contact with the end surface of the open flat anchor 3; the other end of the tool steel strand 2 is connected with a tensioning device, which is a tensioning jack 5. The tool steel strand 2 between the open flat anchor 3 and the tension jack 5 is provided with a single-hole anchorage 4.2 (when using the front clamp jack, the root single-hole anchorage does not need to be set). A steel strand clip 6 is provided between the open flat anchor 3 and the steel strand 1 .

Embodiment 2

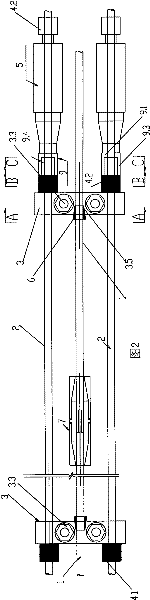

[0044] Such as figure 2 As shown, a single steel strand connector (or extruded anchor nut connector 10) is used to butt tensioned steel strands. It is a schematic diagram of the structure after tensioning is completed.

[0045] It differs from Embodiment 1 in that the steel strands 1 between the two open flat anchors 3 are broken, and the broken steel strands 1 are connected as a whole through a connector 7 .

Embodiment 3

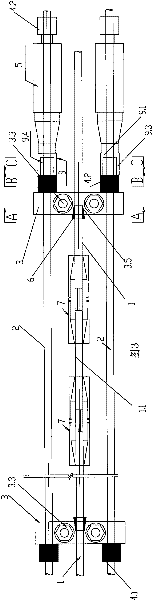

[0047] Such as image 3 As shown, it is used to extend the connection of tensioned steel strands-internal structure. It is a schematic diagram of the structure after tensioning is completed.

[0048] It differs from Embodiment 2 in that after the steel strand 1 between the two open flat anchors 3 is broken, an extended steel strand 1.1 is provided between the broken steel strands 1, and the lengthened steel strand 1.1 and the steel strand 1 The fractured steel strand 1 and the extended steel strand 1.1 are connected as a whole through two connectors 7 between the fractures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com