Full-hydraulic reamer

An eye reamer and full hydraulic technology, which is applied in the direction of drilling equipment, earthwork drilling, drill bits, etc., can solve the problems that it is difficult to fully meet the needs of drilling engineering and the structure of the reamer is not perfect, so as to improve the working life and reliability , the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

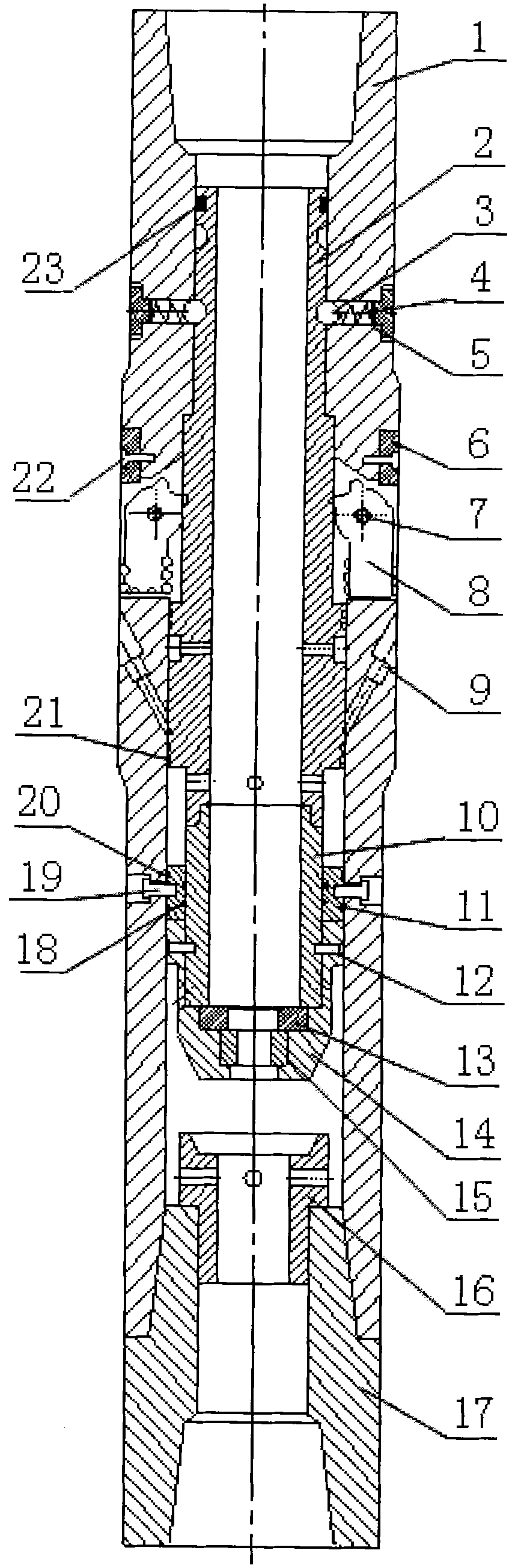

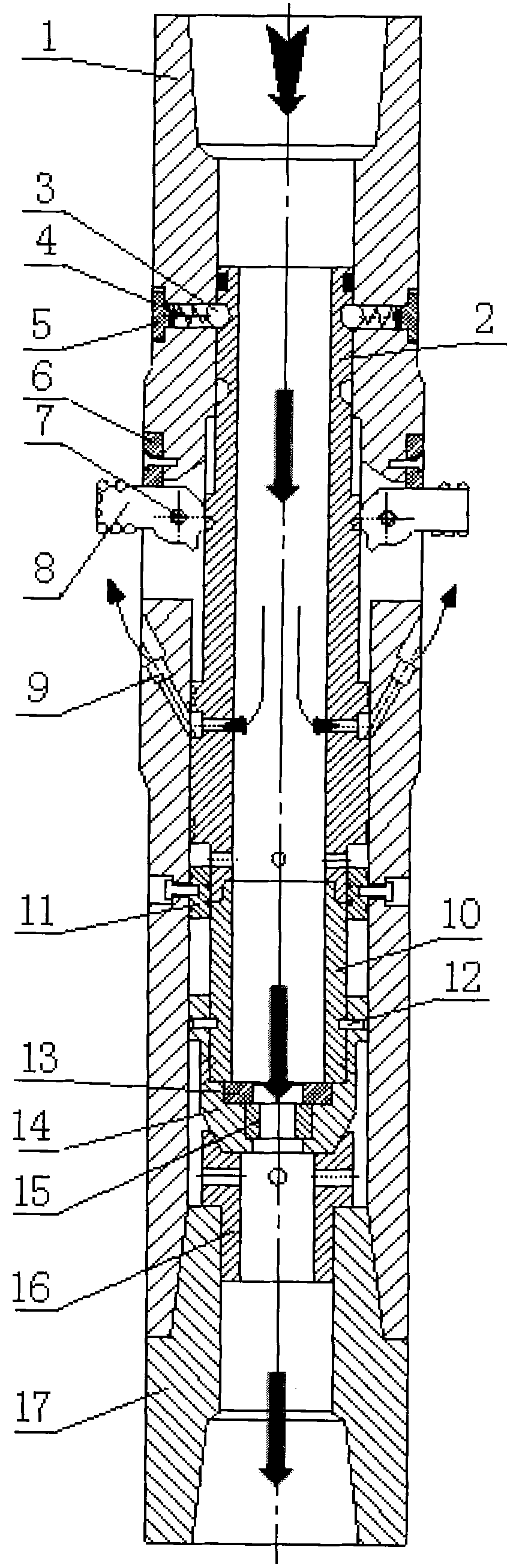

[0034] Embodiment 1: Taking a fully hydraulic eye reamer as an example, the present invention will be further described in detail.

[0035] refer to figure 1 . The full hydraulic eye reamer is mainly composed of a housing 1, a mandrel, a cylindrical pin 7, a reamer blade 8, a sealing limit ring 11, a shear pin 12, a mandrel seat 16, and a lower joint 17. It is characterized in that: The inner cavity of the cylindrical shell 1 has a mandrel;

[0036] The mandrel is mainly composed of the mandrel piston 2, the mandrel nipple 10, the mandrel cap 14, the main nozzle 15 and the main nozzle gland 13. The mandrel piston 2 has a central hole, the outer wall of the mandrel piston 2 is a stepped cylinder, the outer wall of the upper end of the mandrel piston 2 is cylindrical, and the outer wall of the upper end of the mandrel piston 2 is slidingly fitted with the center hole of the upper end of the housing 1; 2 There are two semicircular arc-shaped annular grooves on the outer wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com