Wearproof and anti-backflow double-rubber-plug system for well cementation and using method

A technology of wear-resistant rubber and rubber plug, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc. It can solve problems such as poor cementing quality, increased drilling time, and failure of floating collars, etc., and achieves improved Isolation and cleaning effect, saving drilling time and improving cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

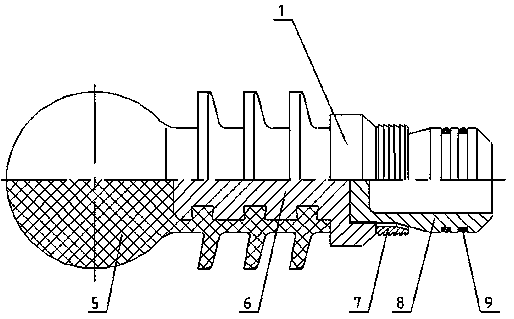

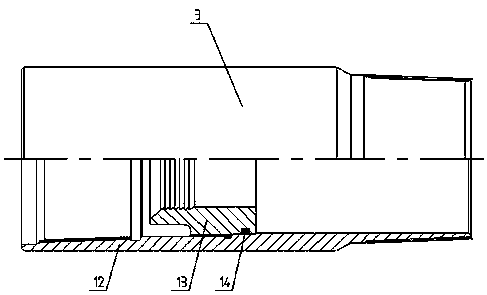

[0037] A wear-resistant and anti-reflux double rubber plug system for well cementing, including a wear-resistant and anti-reflux upper rubber plug 1, a lower rubber plug 2, a bumper seat 3 and a discharge basket 4; the wear-resistant and anti-reflux upper rubber plug 1 is provided with Wing and sealing head 8, the sealing head 8 is provided with self-locking teeth 7, and the wing has a reclining angle; the lower rubber plug 2 is provided with a wing with a reclining angle; the bumper seat 3 includes a shell 12 and a self-locking bumper The seat 13, the outer shell 12 and the self-locking bumper seat 13 are axially connected, the self-locking bumper seat 13 is sealed and fixed in the shell 12, and the inner wall of the self-locking bumper seat 13 is provided with self-locking teeth 7 on the sealing head 8 Matching self-locking structure; after the fins of the lower rubber plug 2 are deformed, the maximum outer diameter of the fins of the lower rubber plug 2 is smaller than the i...

Embodiment 2

[0052] As shown in the figure, a wear-resistant and anti-reflux double rubber plug system for cementing, including wear-resistant and anti-reflux upper rubber plug 1, lower rubber plug 2, bumper seat 3, and discharge basket 4, wear-resistant and anti-reflux glue Plug 1 includes wear-resistant rubber plug body 5, upper rubber plug core 6, self-locking teeth 7 and sealing head 8, etc., lower rubber plug 2 includes ordinary rubber plug body 10 and lower rubber plug core 11, and pressing seat 3 includes shell 12 And self-locking bump seat 13. The back part of the wear-resistant rubber plug body 5 is a sphere or ellipsoid, and the front part is a cylinder, on which a plurality of fins with reclining angles are arranged at intervals, and the rear part of the outer wall of the upper rubber plug core 6 is arranged at intervals A plurality of annular grooves, the outer wall of the front part is a cone cylinder, and the wear-resistant rubber plug body is embedded and vulcanized on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com