Automatic lifting drilling machine for high-position punching of medium-thickness coal seams and implementation method thereof

An automatic lifting and thick coal seam technology, which is applied to drilling equipment and methods, rotary drilling rigs, earthwork drilling and mining, etc., can solve the problems of inability to effectively perform high-level drilling in medium-thick coal seams and inflexible adjustment of drilling angles, and achieve Improve the efficiency and safety of high-position drilling, improve the accuracy and efficiency of drilling, and improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

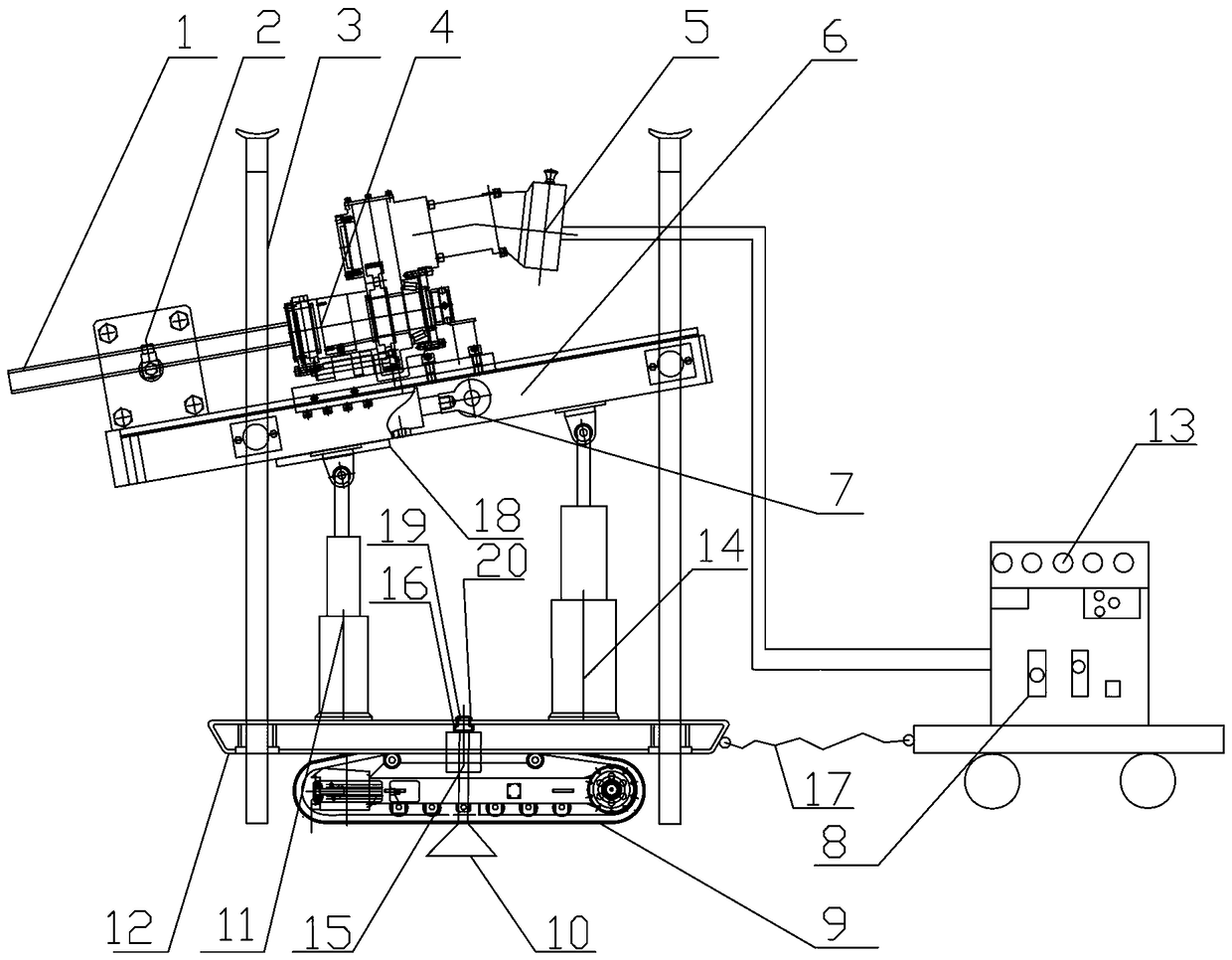

[0032] Example 1, such as Figure 1 to Figure 4 As shown, an automatic lifting drilling rig for high-level drilling in medium-thick coal seams includes a lifting unit, a power unit, a rotary unit, a walking unit and a drilling unit. The lifting unit is connected to the rotary unit and the drilling unit, and the power unit is connected to the lifting unit and the rotary unit. , walking unit and punching unit.

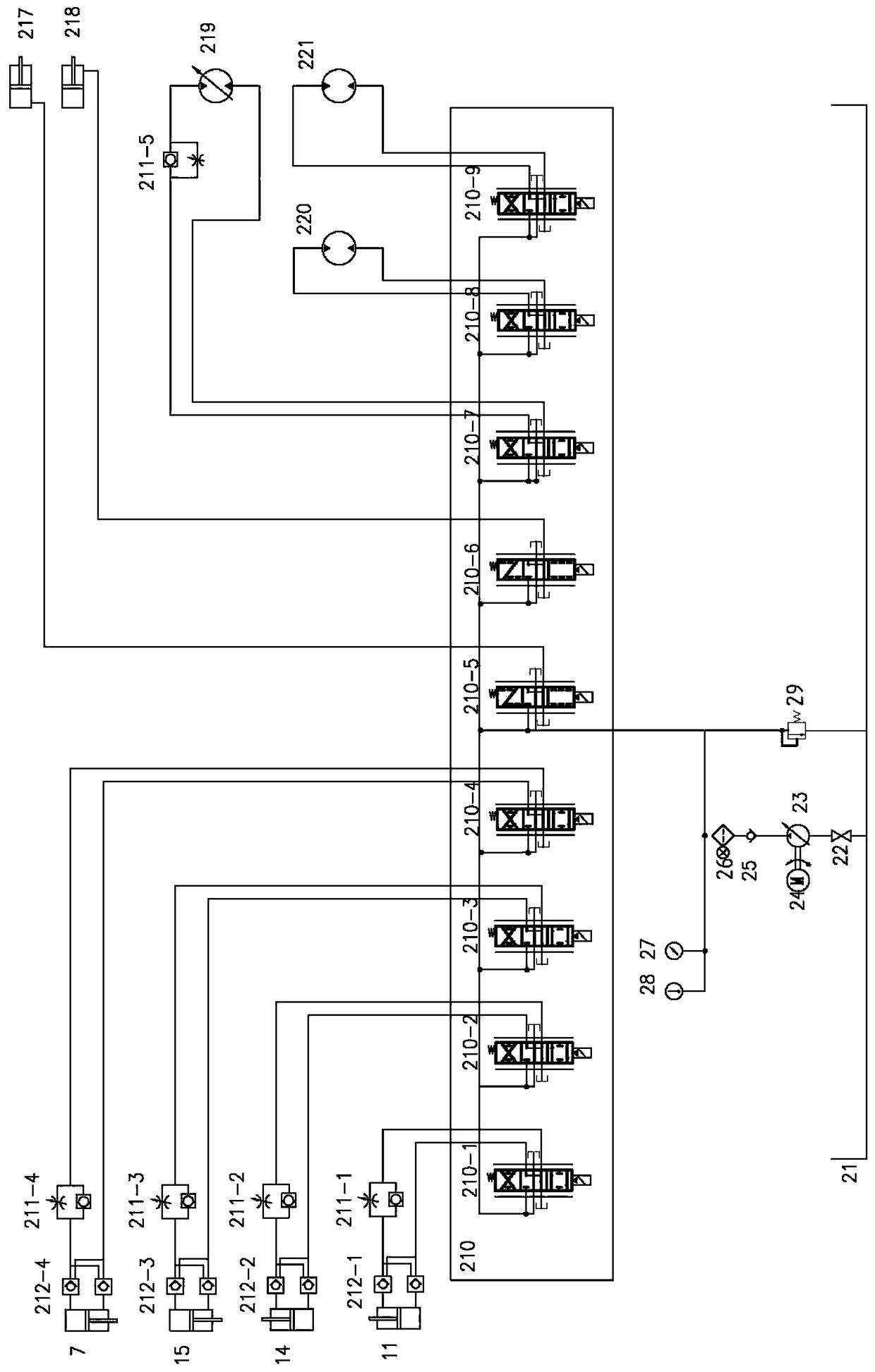

[0033] The lifting unit includes a front hydraulic cylinder 11 and a rear hydraulic cylinder 14. The front hydraulic cylinder 11 and the rear hydraulic cylinder 14 are two-stage telescopic hydraulic cylinders. The cylinder bodies of the front hydraulic cylinder 11 and the rear hydraulic cylinder 14 pass through movable pin holes respectively. Fixed on the front and rear ends of the rotary unit, the piston rod of the front hydraulic cylinder 11 and the piston rod of the rear hydraulic cylinder 14, the front hydraulic cylinder 11 and the rear hydraulic cylinder 14 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com