Preparation method of lactic acid bacterium fermented sour soybean milk and the lactic acid bacterium fermented sour soybean milk

A technology of lactic acid bacteria fermentation and sour soy milk, which is applied in dairy products, milk substitutes, applications, etc. It can solve the problems of poor flavor, strong beany smell, short shelf life, etc., and achieve refreshing chewing, rich taste types, and stickiness good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

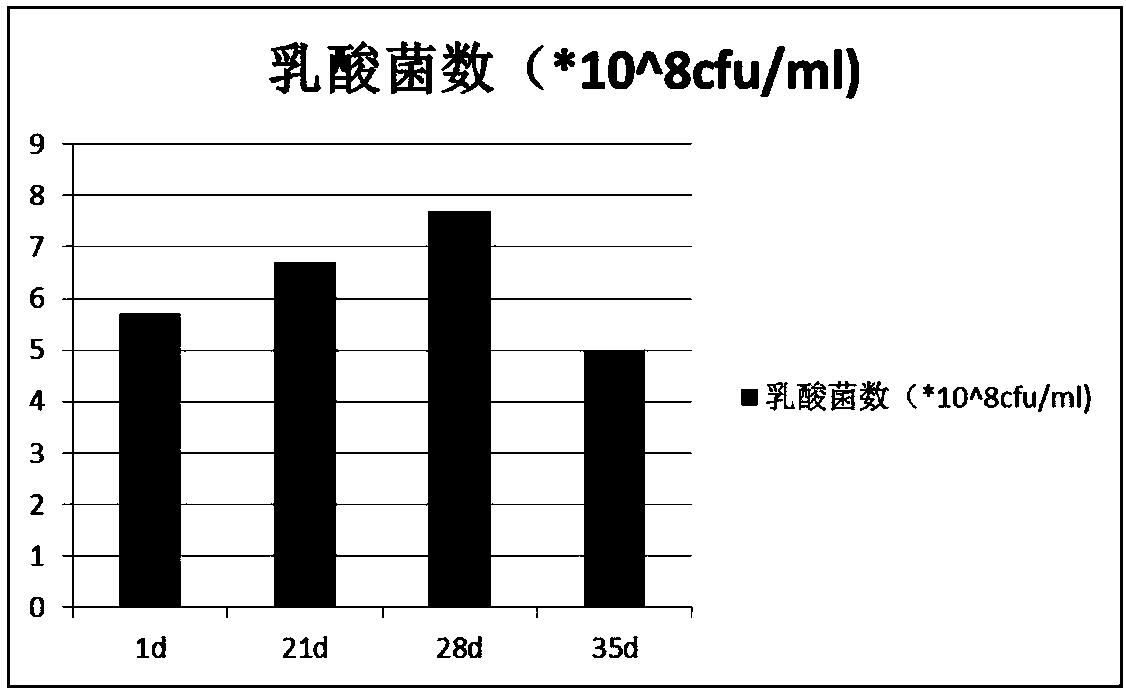

Image

Examples

Embodiment 1

[0034] Weigh 7.5g / 100g of fishy bean milk powder, add water and stir until completely dissolved.

[0035] Weigh 9g / 100g of sucrose, add water and stir until completely dissolved.

[0036] Stabilizer Weigh 0.02g / 100g of modified starch and 0.008g / 100g of gelatin, add water until completely dissolved.

[0037] (1) Deploying and constant volume Stir the stabilizer evenly according to the production needs and pour it into the soy milk, mix the materials evenly, add water to make the volume up to 100g.

[0038] (2) Homogenization Under the process parameters of pressure 20Mpa, homogenize the material and liquid.

[0039] (3) Sterilize the homogeneous feed liquid with the process parameters of 85° C. and 5 minutes for pasteurization.

[0040] (4) Inoculate with 0.01% starter, the starter is Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus, and Bifidobacterium lactis mixed in a ratio of 6:1:2:1, and stirred at a speed of 10 rpm.

[0041] (5) Fermenta...

Embodiment 2

[0045] Weigh 7.5g / 100g of fishy bean milk powder, add water and stir until completely dissolved.

[0046] Weigh 9g / 100g of sucrose, add water and stir until completely dissolved.

[0047] Stabilizer Weigh 0.01g / 100g of modified starch and 0.09g / 100g of gelatin, add water until completely dissolved.

[0048] (1) Deploying and constant volume Stir the stabilizer evenly according to the production needs and pour it into the soy milk, mix the materials evenly, add water to make the volume up to 100g.

[0049] (2) Homogenization Under the process parameters of pressure 20Mpa, homogenize the material and liquid.

[0050] (3) Sterilize the homogeneous feed liquid with the process parameters of 85° C. and 5 minutes for pasteurization.

[0051] (4) Inoculate with 0.008% starter, the starter is Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus, and Bifidobacterium lactis mixed in a ratio of 6:3:0.5:0.5 and stirred at a speed of 10 rpm.

[0052] (5) Ferme...

Embodiment 3

[0056] Weigh 8.4g / 100g of fishy bean milk powder, add water and stir until completely dissolved.

[0057] Weigh 9g / 100g of sucrose, add water and stir until completely dissolved.

[0058] Stabilizer Weigh 0.03g / 100g of modified starch and 0.09g / 100g of gelatin, add water until completely dissolved.

[0059] (1) Deploying and constant volume Stir the stabilizer evenly according to the production needs and pour it into the soy milk, mix the materials evenly, add water to make the volume up to 100g.

[0060] (2) Homogenization Under the process parameters of pressure 15Mpa, homogenize the material and liquid.

[0061] (3) Sterilize the homogeneous feed liquid with the process parameters of 85° C. and 5 minutes for pasteurization.

[0062] (4) Inoculate with 0.015% starter, the starter is Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus, and Bifidobacterium lactis mixed in a ratio of 7:2:1:1, and stirred at a speed of 10 rpm.

[0063] (5) Fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com