Non-oriented silicon steel with excellent magnetism and for drive motor of electric car, and production method thereof

A technology for electric vehicles and driving motors, applied in the field of non-oriented silicon steel production, can solve the problems of broken belt, reduced magnetic induction, unreasonable composition and process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

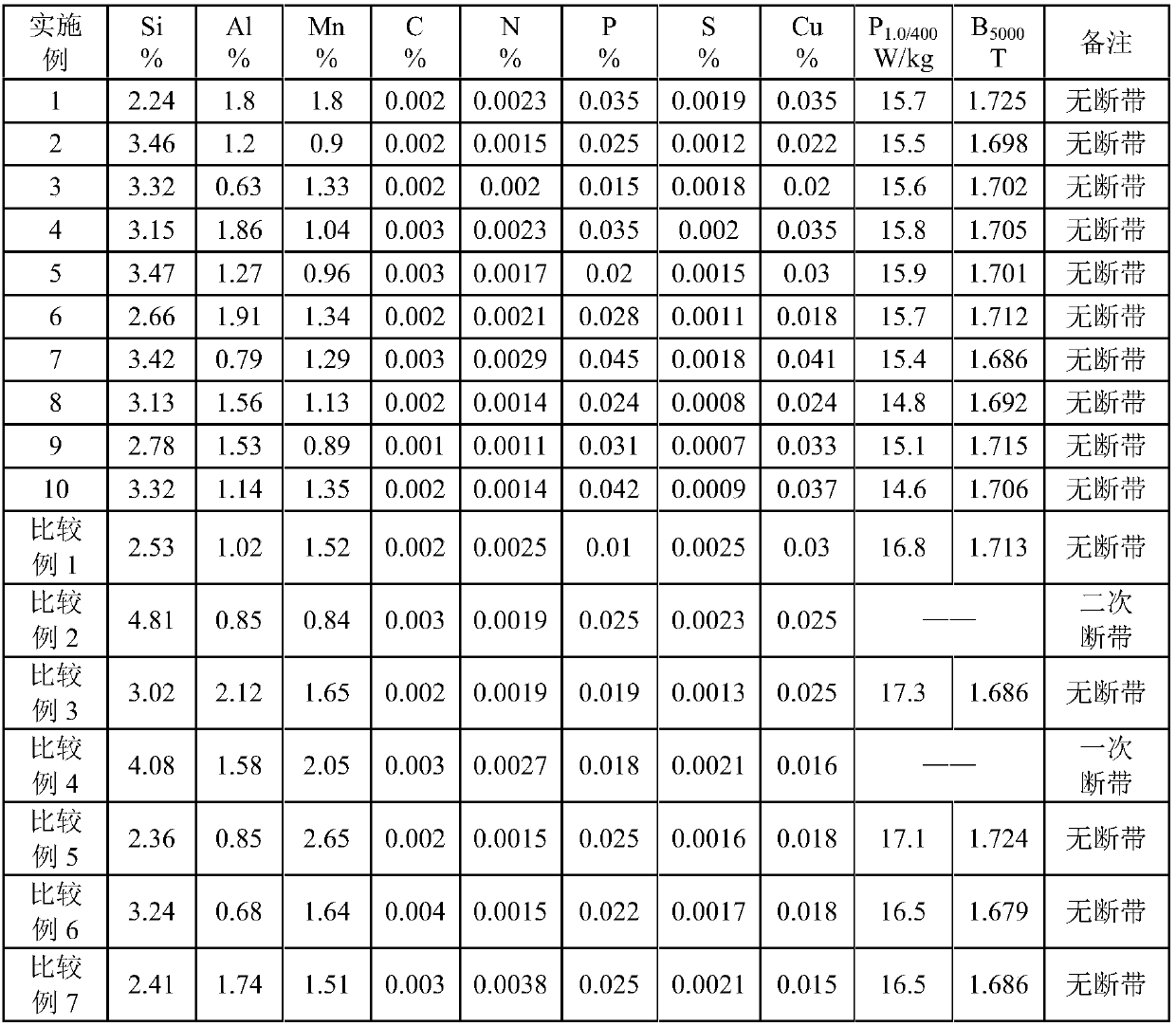

Embodiment 1

[0073] Using converter smelting and RH vacuum refining, the chemical composition obtained in weight percentage is shown in Table 1; the test steel hot rolling heating temperature is 1150 ° C, and the furnace time is 120 min; the rough rolling exit temperature is 880 ° C; the rough rolling exit thickness is 28 mm; the finishing rolling temperature 750°C; the reduction ratio of the 4 passes before finish rolling is 88%; the coiling temperature is 690°C; the thickness of the hot-rolled sheet is 2.0mm. The temperature in the soaking section of the normalization continuous furnace is 900°C; the soaking time is 3 minutes; the hot-rolled plate is cold-rolled by a cold rolling method after pickling, and the thickness of the finished product is 0.35mm; the annealing soaking temperature is 960°C, and the soaking time is 2 minutes. Control the cooling rate at 8 °C / s from the annealing soaking temperature to 600 °C, and control the cooling rate at 45 °C / s during cooling from less than 600 ...

Embodiment 2

[0079] According to the chemical composition of Example 3 in Table 1, and using the same process conditions, that is, using a converter and a vacuum furnace to smelt, followed by continuous casting; the heating temperature of the continuous casting slab is 1130 ° C, and the time in the furnace is 120 min; the exit temperature of rough rolling at 860°C; the exit thickness of rough rolling is 30mm; the finish rolling temperature is at 730°C; The temperature in the soaking section of the chemical continuous furnace is 860 ° C, and the soaking time is 4 minutes; after pickling, the hot-rolled plate is cold-rolled to the thickness of the finished product by a cold rolling method, and the thickness of the finished product is 0.30 mm; the soaking time for annealing is 2.5 minutes; according to the formula: 850 +100×t≤T≤950+100×t, the annealing soaking temperature should be within the range of 880-980°C and the annealing soaking temperature is outside the range of 880-980°C of the pres...

Embodiment 3

[0086] According to the chemical composition of Example 4 in Table 1, and using the same process conditions, that is, using a converter and a vacuum furnace to smelt, followed by continuous casting; the heating temperature of the continuous casting slab is 1055 ° C, and the time in the furnace is 135 min; the exit temperature of rough rolling at 875°C; the exit thickness of rough rolling is 33mm; the final rolling temperature is at 725°C; the total reduction rate of the 4 passes before finish rolling is 83%; the coiling temperature is at 676°C; the thickness of hot-rolled sheet is 2.3mm; The temperature in the soaking section of the furnace is 895°C, and the soaking time is 3 minutes; after pickling, the hot-rolled plate is cold-rolled to the thickness of the finished product by a cold rolling method, and the thickness of the finished product is 0.27mm; the soaking time for annealing is 1.5 minutes; according to the formula: 850+100 ×t≤T≤950+100×t, the annealing soaking tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com