High thermal conductivity magnesium alloy and preparation method thereof

A magnesium alloy, high thermal conductivity technology, applied in the field of metal material magnesium alloy, can solve the problems of inability to meet mechanical properties, decreased thermal conductivity, low thermal conductivity, etc., and achieves improved mechanical properties and thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In the specific implementation process, the steps of the preparation method of the high thermal conductivity magnesium alloy of the present invention are as follows:

[0024] 1) Use pure magnesium ingots, pure zinc ingots, pure tin ingots, pure aluminum ingots and magnesium-manganese intermediate alloys as raw materials, make ingredients according to the alloy design component content, and put them in a drying oven to preheat to about 200°C.

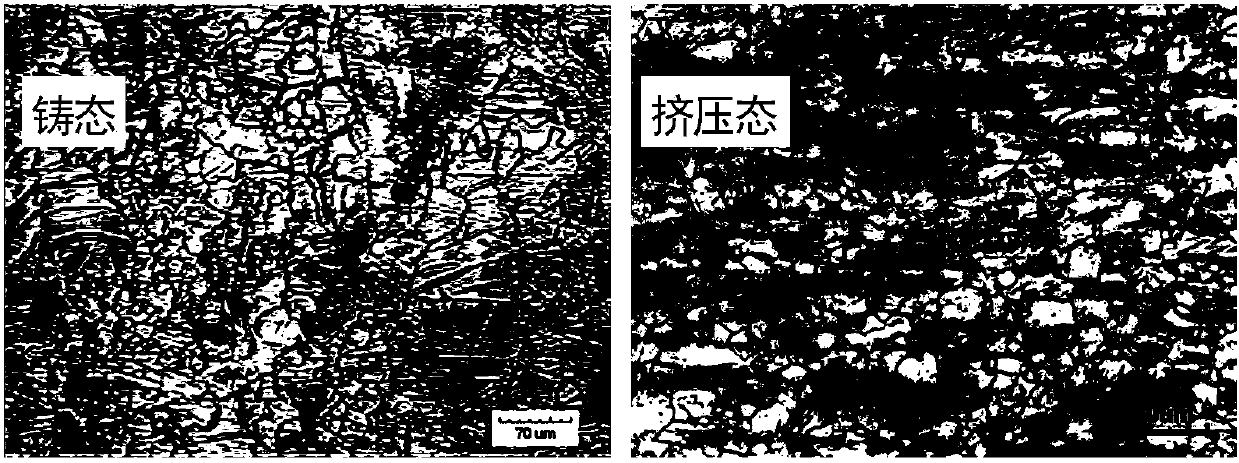

[0025] 2) Mg is smelted in an iron crucible at a melting temperature of 730°C. After the pure magnesium is completely melted, the preheated pure metal Zn, Sn, Al and Mg-10wt.%Mn master alloy are added in turn for alloying, and the heat preservation is 15 ~20min, after all melting, remove the slag and blow into high-purity argon gas for refining for 3~5min, let it stand for 5~20min, adjust the temperature of the alloy melt to 700~720℃, and use metal molds or semi-continuous casting crystallizers to cast into Ingots for casting or d...

Embodiment 1

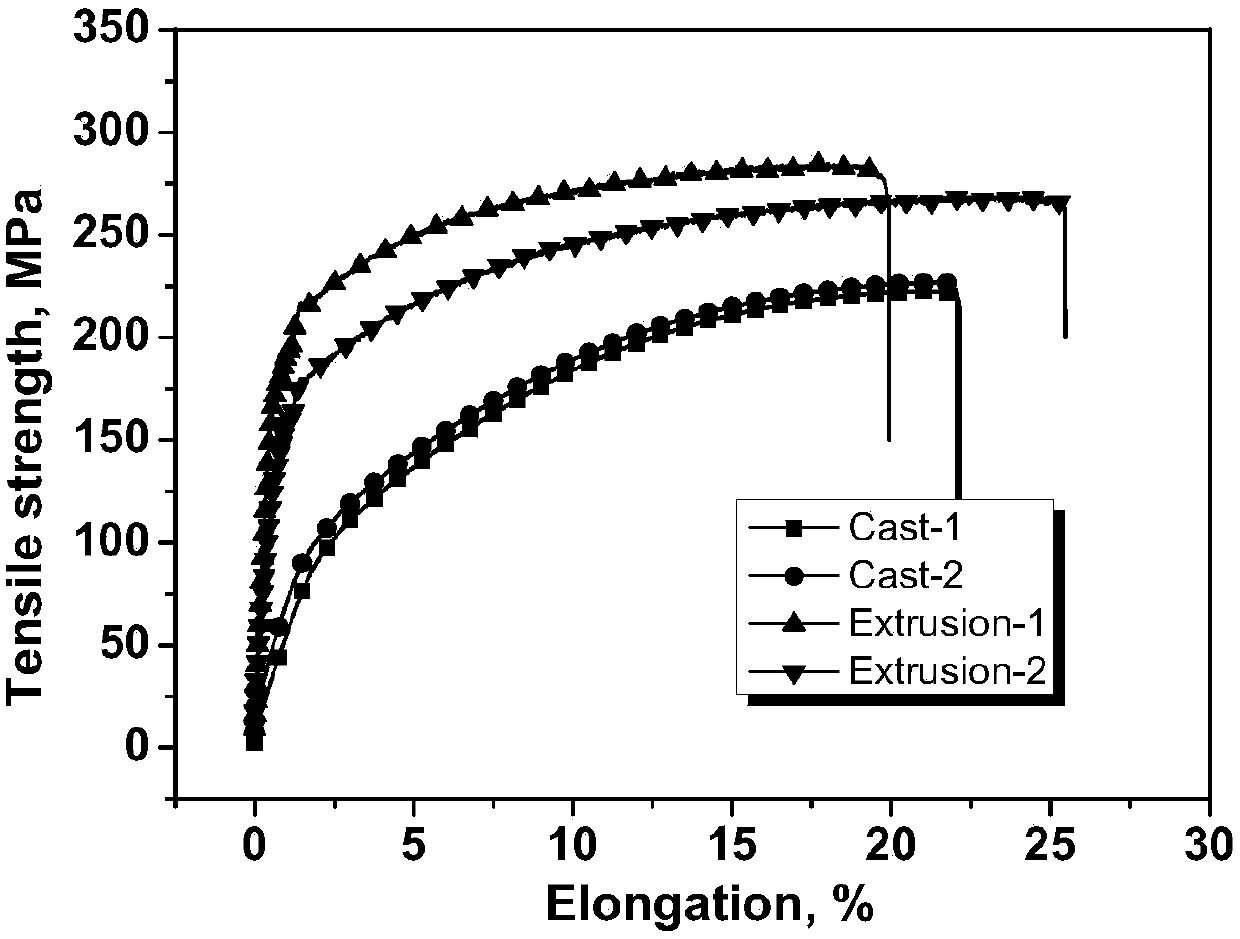

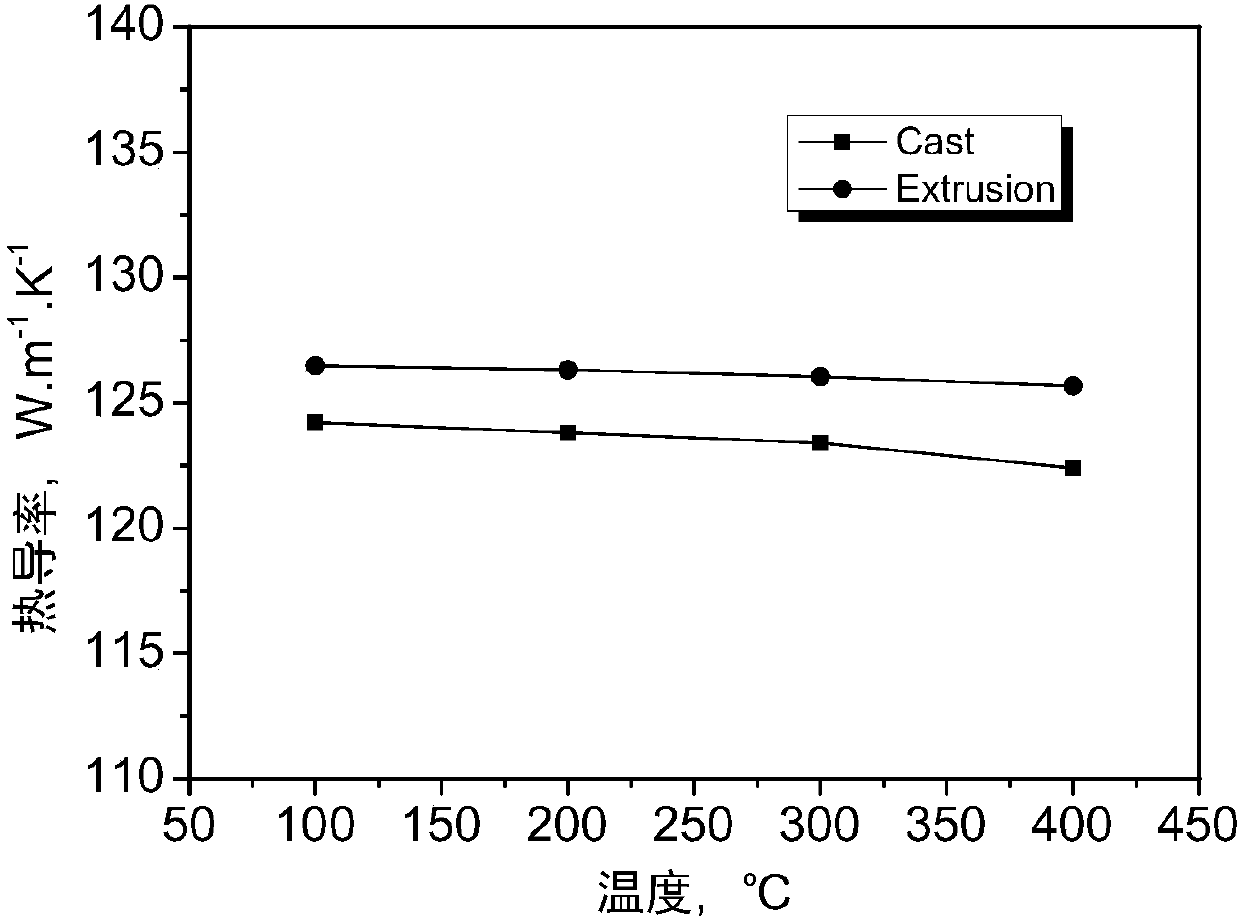

[0031] In this embodiment, the components and weight percentages of the high thermal conductivity magnesium alloy are: 4.0% Zn, 2.5% Sn, 1.0% Al, 0.5% Mn, the rest are Mg and unavoidable impurity elements, and the content of impurity elements is <0.05% .

[0032] In this embodiment, the preparation method of the high thermal conductivity magnesium alloy is as follows:

[0033] (1) Ingredients: The raw materials are metal Mg, metal Zn, metal Sn, metal Al and Mg-10wt.%Mn master alloy, and the components and weight percentages of the alloy are: 4.0% Zn, 2.5% Sn, 1.0% Al, 0.5% Mn, the rest is Mg;

[0034] (2) Melting: Using iron crucible, melting in a resistance furnace, controlling the melting temperature to 730°C, using CO 2 and SF 6 Mixed as protective gas (by volume percentage, 99% CO 2 +1%SF 6 ), the raw material is preheated at 200°C, firstly add metal Mg, after metal Mg is completely melted, add Mg-Mn intermediate alloy, smelt for 15 minutes, finally add metal Zn, Sn a...

Embodiment 2

[0038] In this embodiment, the components and weight percentages of the high thermal conductivity magnesium alloy are: 3.5% Zn, 2.0% Sn, 0.8% Al, 0.3% Mn, the rest are Mg and unavoidable impurity elements, and the content of impurity elements is <0.05% .

[0039] In this embodiment, the preparation method of the high thermal conductivity magnesium alloy is as follows:

[0040] (1) Ingredients: The raw materials are metal Mg, metal Zn, metal Sn, metal Al and Mg-10wt.%Mn master alloy, the components of the alloy and their weight percentages are: 3.5%Zn, 2.0%Sn, 0.8%Al, 0.3% Mn, the rest is Mg;

[0041] (2) Melting: Using iron crucible, melting in a resistance furnace, controlling the melting temperature to 730°C, using CO 2 and SF 6 Mixed as protective gas (by volume percentage, 99% CO 2 +1% SF 6 ), the raw material is preheated at 200°C, firstly add metal Mg, after metal Mg is completely melted, add Mg-Mn intermediate alloy, smelt for 15 minutes, finally add metal Zn, Sn a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com