Matt PC/PBT alloy material and preparation method thereof

An alloy material and matte technology, which is applied in the field of matte PC/PBT alloy materials and their preparation, can solve the problems of accelerating the decomposition of ester groups in the alloy, reducing the thermal stability of the PC/PBT alloy, and reducing the thermal stability of the PC/PBT alloy material. , to achieve the effect of increasing extinction, easy availability of raw materials, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

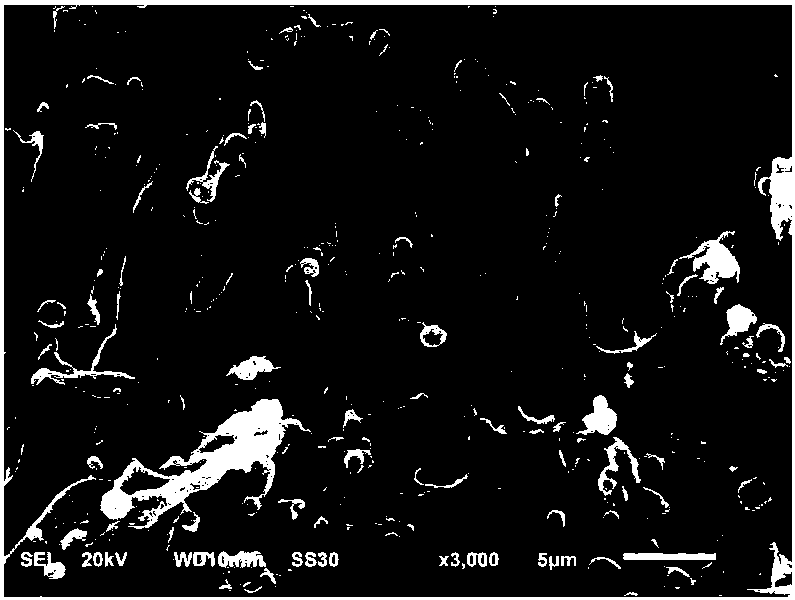

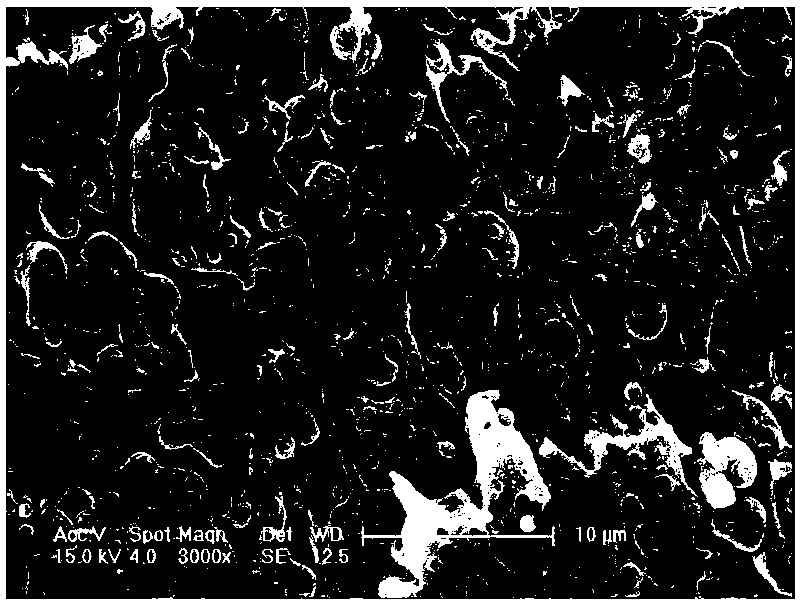

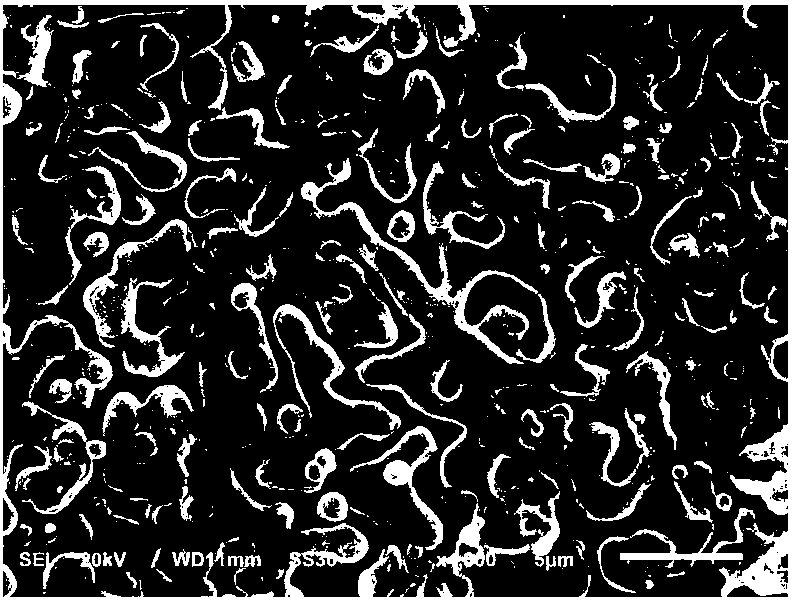

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further described below in conjunction with embodiments.

[0029] The matt PC / PBT alloy materials in the examples were prepared according to the following preparation methods, and the proportions of the components in Examples 1-3 are shown in Table 1:

[0030] Mix 50-60 parts of bisphenol A PC resin, 25-45 parts of PBT resin, 5-15 parts of ABS resin, 3-6 parts of toughening agent, 1-3 parts of compatibilizer, 1-4 parts of matting agent, 0.2 -0.6 parts of antioxidant, 0.2-0.6 parts of lubricant, and 0.1-0.5 parts of transesterification inhibitor are added to a high-speed mixer and mixed for 2-5 minutes, where the speed is 300-400rpm; the mixed materials are added to the meshing type In the parallel co-rotating twin-screw extruder, the matt PC / PBT alloy is obtained by melting, extruding, and pelletizing; the temperature of the extruder barrel is 220-250°C and the vacuum degree is -0.04--0.1MPa. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com