A kind of matte finish paint and its preparation method and application method

A topcoat, matte technology, applied in the field of painting, which can solve the problems of transparency and recoatability, limited topcoat transparency and recoatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

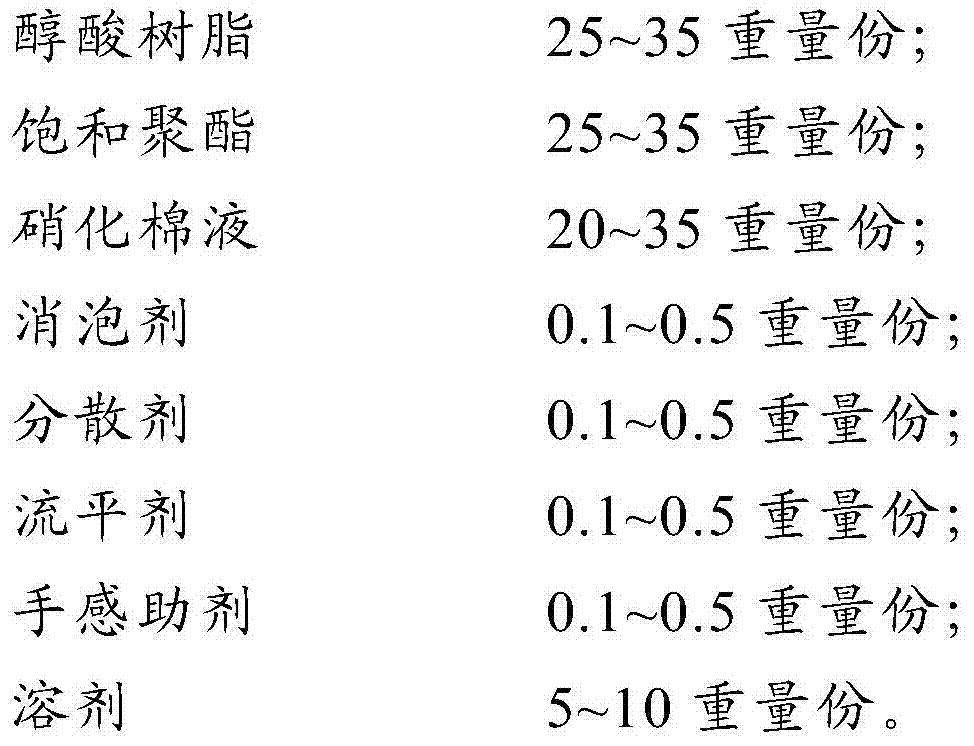

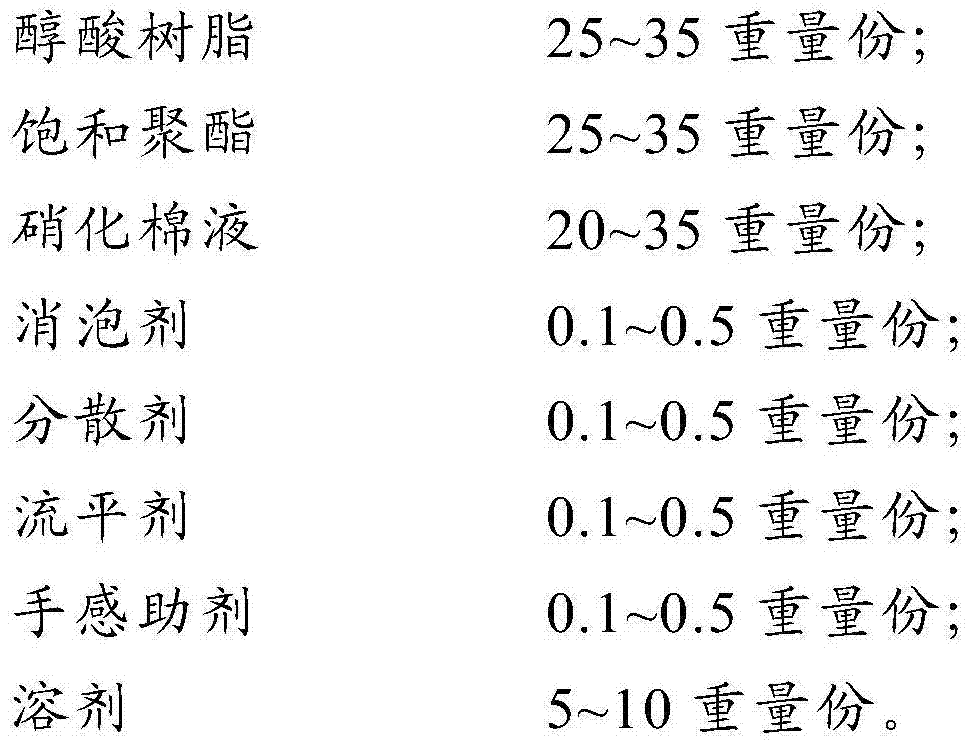

[0065] The present invention also provides a method for preparing the above-mentioned matte finish, which comprises: mixing 25-35 parts by weight of alkyd resin, 25-35 parts by weight of saturated polyester and 20-35 parts by weight of nitrocellulose liquid to obtain 400 Stir at a rotation speed of ~800rpm, add 0.1-0.5 parts by weight of defoamer, 0.1-0.5 parts by weight of dispersant, 0.1-0.5 parts by weight of leveling agent and 0.1-0.5 parts by weight of hand-feel additives, at 800-1200rpm Disperse to the fineness ≤ 20μm, then add 5-10 parts by weight of solvent, stir and disperse to obtain a matte finish.

[0066] The present invention has no special restrictions on the source of all raw materials, as long as they are commercially available. Wherein, the alkyd resin, saturated polyester, nitrocellulose liquid, defoaming agent, dispersant, leveling agent, hand feeling assistant and solvent are all the same as described above, and will not be repeated here.

[0067] Mix alkyd re...

Embodiment 1

[0088] 1.1 Add 30 parts by weight of nitrocellulose to 59.8 parts by weight of n-butyl acetate, and after soaking it to be completely wetted, add 0.2 parts by weight of nitrocellulose anti-yellowing additive under low-speed stirring, and disperse at 800rpm for 30 minutes to completely dissolve to obtain nitrocellulose liquid.

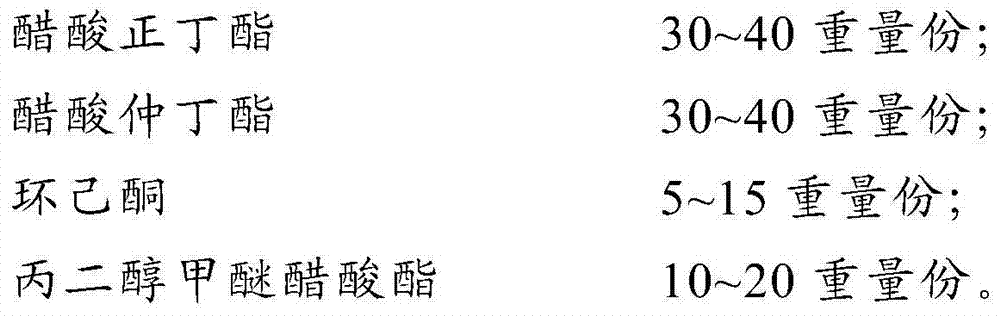

[0089] 1.2 Add 30 parts by weight of saturated polyester and 25 parts by weight of the nitrocellulose liquid obtained in 1.1 to 35 parts by weight of alkyd resin, stir and disperse at 600 rpm for 6 minutes, and then add 0.3 parts by weight of defoamer, 0.3 parts by weight of dispersant, 0.3 Parts by weight of leveling agent and 0.5 parts by weight of hand-feel additives, disperse at 1000rpm for 10min at high speed until the fineness is ≤20μm, then add 8.6 parts by weight of solvent, disperse at 600rpm for 7min until uniform, filter to obtain matte finish.

[0090] 1.3 Mix the matte finish, curing agent and thinner obtained in 1.2 according to the mass ratio o...

Embodiment 2

[0094] 2.1 Add 30 parts by weight of saturated polyester and 30 parts by weight of the nitrocellulose liquid obtained in 1.1 to 30 parts by weight of alkyd resin, stir and disperse at 600 rpm for 6 minutes, and then add 0.3 parts by weight of defoamer, 0.3 parts by weight of dispersant, 0.3 Parts by weight of leveling agent and 0.5 parts by weight of hand-feel additives, disperse at 1000rpm for 10min at high speed until the fineness is ≤20μm, then add 8.6 parts by weight of solvent, disperse at 600rpm for 7min until uniform, filter to obtain matte finish.

[0095] 2.2 Mix the matte finish, curing agent and thinner obtained in 2.1 according to the mass ratio of 1:0.7:0.6, filter with 500 mesh and let it stand for 15 minutes, then spray it. After drying for 24 hours, the paint film can be obtained. Its gloss is 5 points of light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com