Method for preparing high-purity molybdenum trioxide from molybdenum concentrate through hydrometallurgy

A technology of molybdenum trioxide and hydrometallurgy, which is applied in the field of molybdenum industry and hydrometallurgy, can solve the problems of lack of international competitiveness, low purity, environmental pollution, etc., achieve no environmental pollution, high comprehensive recovery rate, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

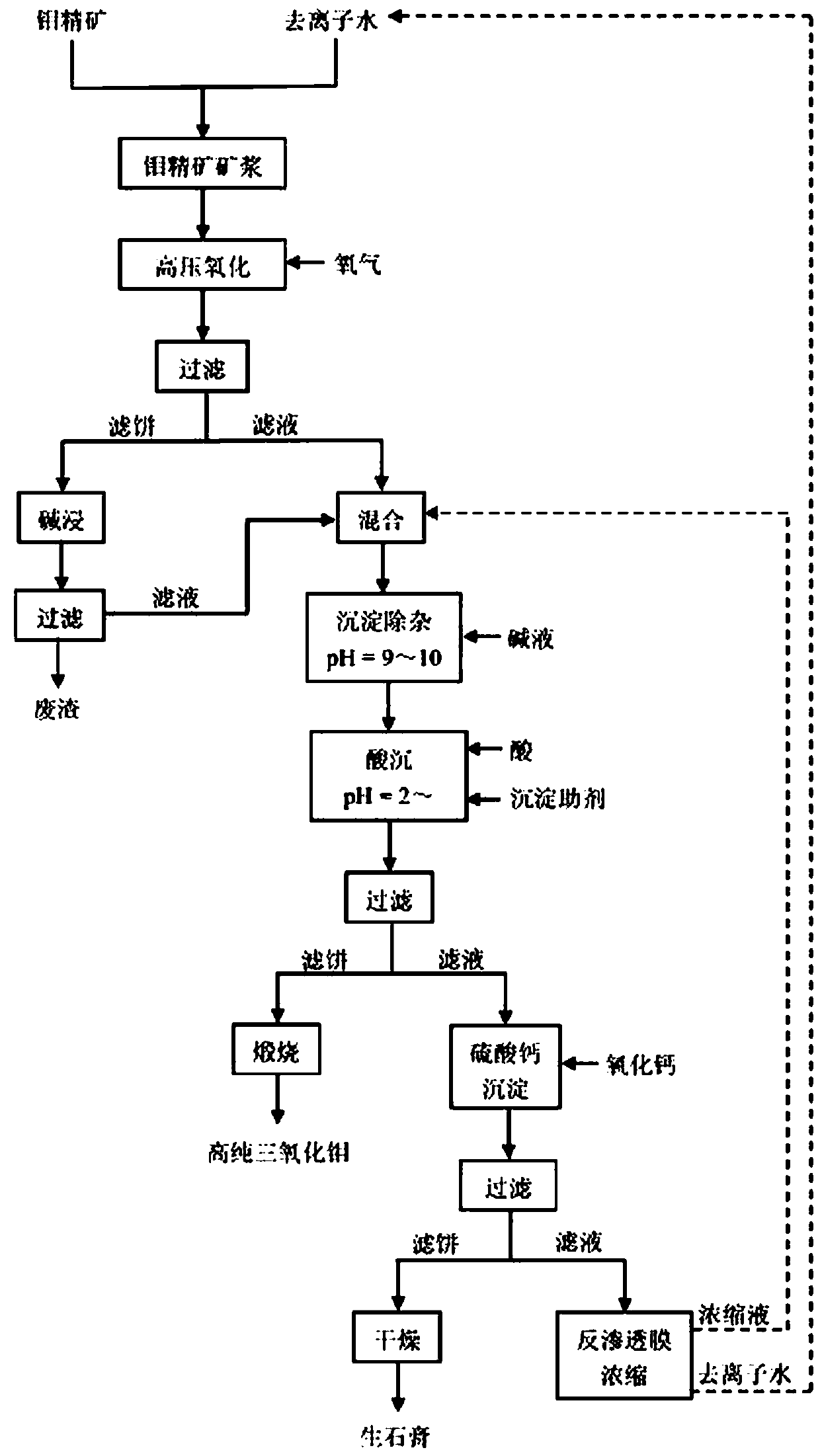

Image

Examples

Embodiment 1

[0050] The mass percentage of molybdenum in the molybdenum concentrate processed in this embodiment is 15%, and the particle size of the molybdenum concentrate is -150 mesh-+200 mesh. method, the method includes the following steps:

[0051] (1) Mix molybdenum concentrate and deionized water uniformly at a solid-to-liquid ratio of 1:2 (g:mL) to make molybdenum concentrate slurry;

[0052] (2) Pour the molybdenum concentrate slurry prepared in step (1) into a high-pressure reaction kettle, and carry out high-pressure oxidation decomposition reaction at 180 °C and an oxygen partial pressure of 3.0 MPa. The reaction time is 2 hours, and the high-pressure oxidation decomposition reaction is obtained. Molybdenum concentrate slurry;

[0053] (3) Using a centrifuge to filter the molybdenum concentrate slurry after the high-pressure oxidation decomposition reaction in step (2) to obtain a primary filter cake and a primary filtrate;

Embodiment 2

[0062] The mass percentage of molybdenum in the molybdenum concentrate processed in this embodiment is 30%, and the particle size of the molybdenum concentrate is -150 mesh-+200 mesh. method, the method includes the following steps:

[0063] (1) Mix molybdenum concentrate and deionized water uniformly at a solid-to-liquid ratio of 1:5 (g:mL) to make molybdenum concentrate slurry;

[0064] (2) Pour the molybdenum concentrate slurry prepared in step (1) into a high-pressure reaction kettle, and carry out high-pressure oxidation decomposition reaction at 200 ° C and an oxygen partial pressure of 3.0 MPa. The reaction time is 2 h, and the high-pressure oxidation decomposition reaction is obtained. Molybdenum concentrate slurry;

[0065] (3) Using a centrifuge to filter the molybdenum concentrate slurry after the high-pressure oxidation decomposition reaction in step (2) to obtain a primary filter cake and a primary filtrate;

[0066] (4) The primary filter cake obtained in step ...

Embodiment 3

[0074] The mass percentage of molybdenum in the molybdenum concentrate processed in this embodiment is 45%, and the particle size of the molybdenum concentrate is -150 mesh-+200 mesh. method, the method includes the following steps:

[0075] (1) Mix molybdenum concentrate and deionized water uniformly at a solid-to-liquid ratio of 1:7 (g:mL) to make molybdenum concentrate slurry;

[0076] (2) Pour the molybdenum concentrate slurry prepared in step (1) into the high-pressure reaction kettle, and carry out high-pressure oxidation decomposition reaction at 220°C and oxygen partial pressure of 3.5MPa. The reaction time is 3 hours, and the high-pressure oxidation decomposition reaction is obtained. Molybdenum concentrate slurry;

[0077] (3) Using a centrifuge to filter the molybdenum concentrate slurry after the high-pressure oxidation decomposition reaction in step (2) to obtain a primary filter cake and a primary filtrate;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com