Household appliance gas stove inner and outer burner cap machining device

A technology for household appliances and processing devices, applied in the field of gas stoves, can solve the problems of manual control of polishing quality, difficulty in achieving unified standards, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

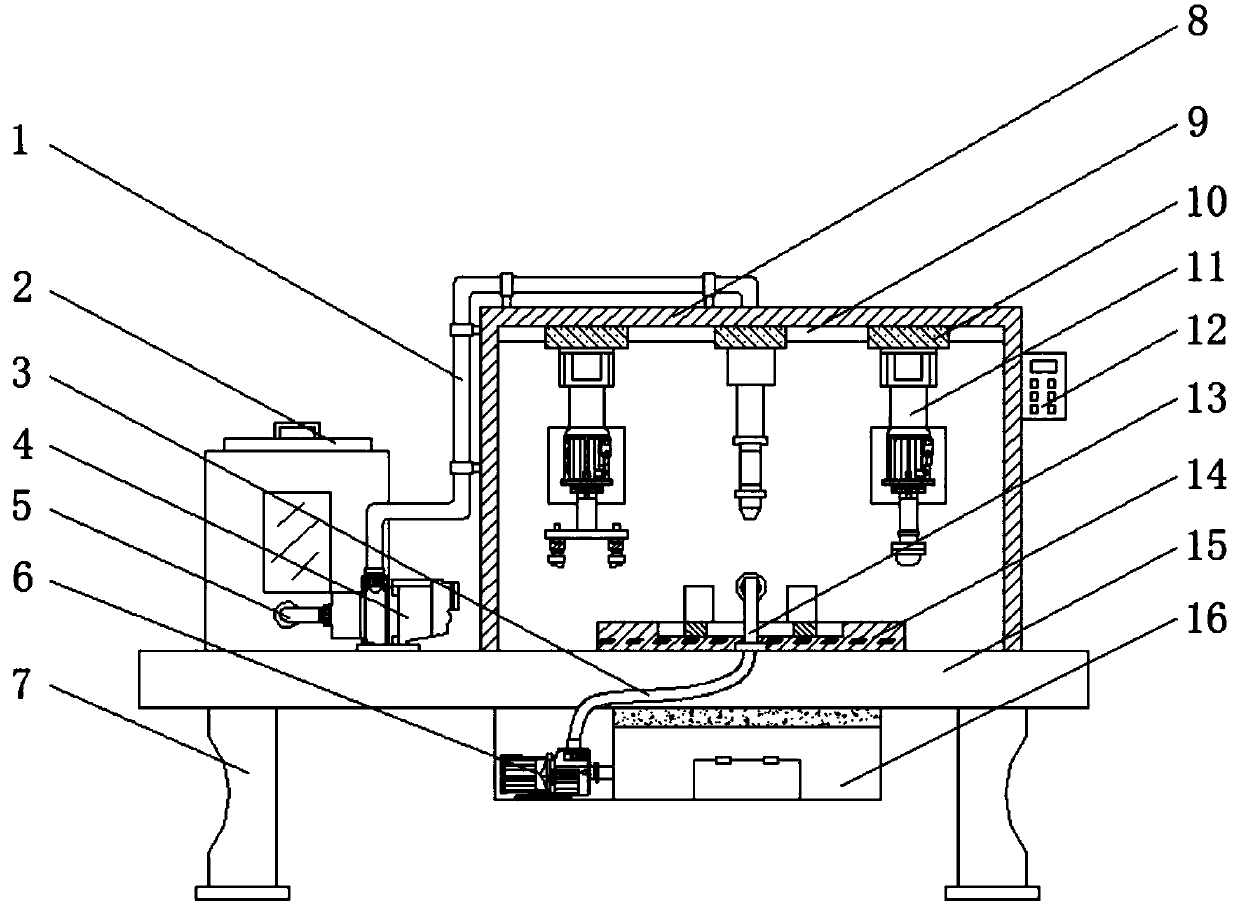

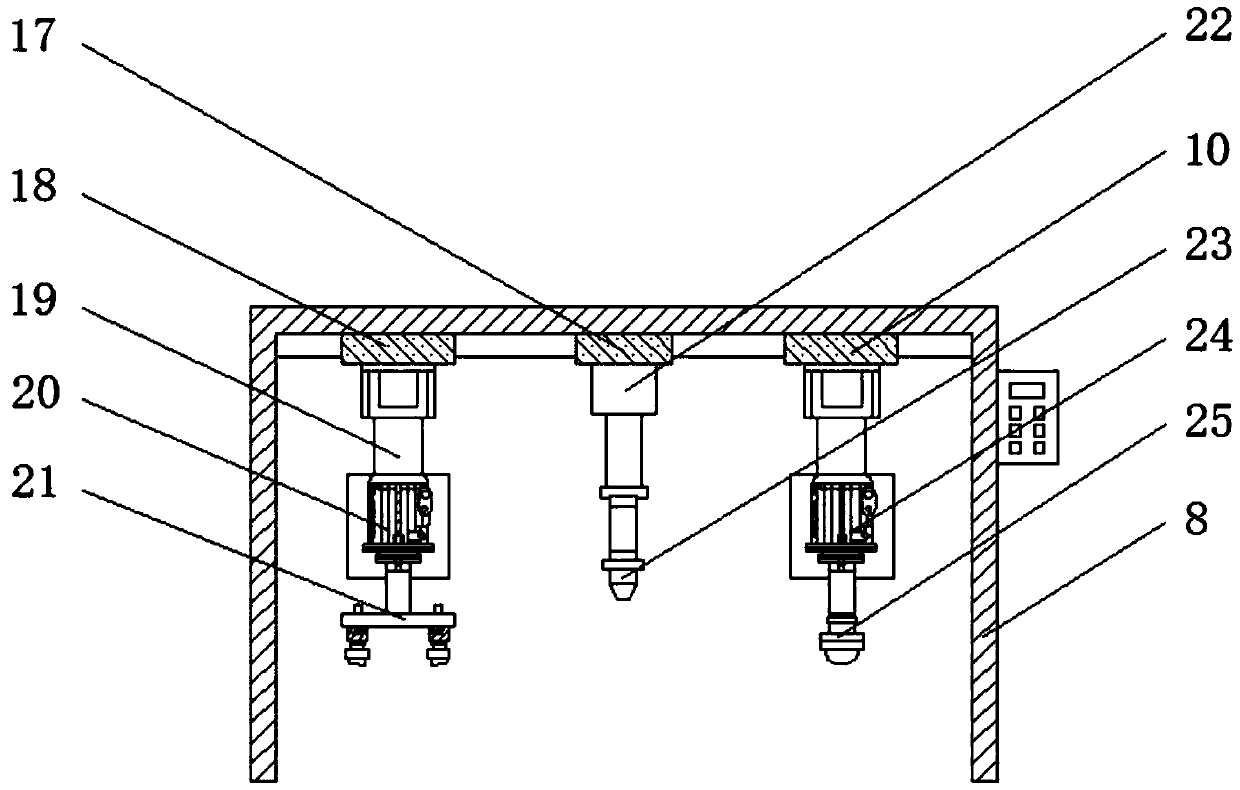

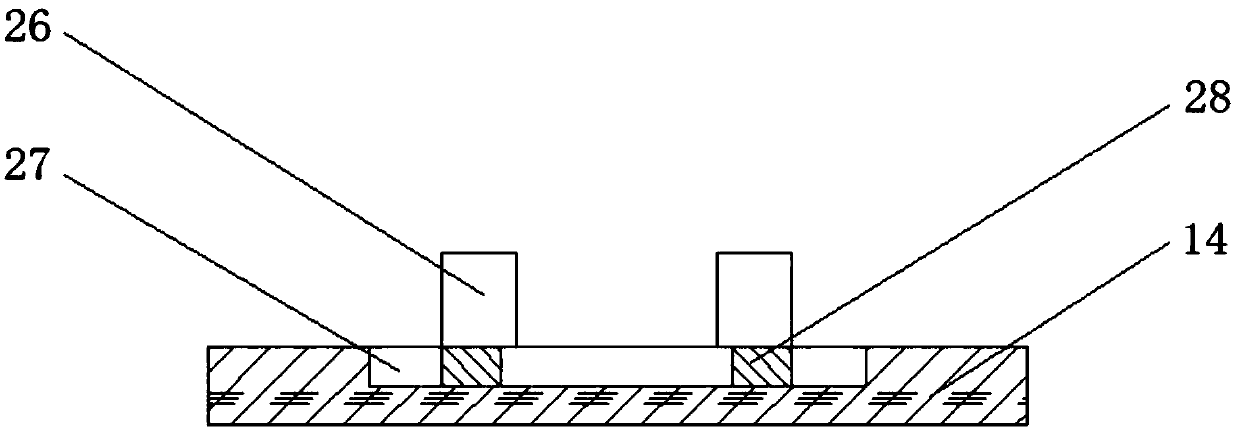

[0020] Such as Figure 1 to Figure 5 As shown, a domestic appliance gas stove inner and outer fire cover processing device includes a paint storage cylinder 2, a mounting frame 8, a polishing table 14 and a base 15, and four corners at the bottom of the base 15 are equipped with outriggers 7 and 7 The bottom ends of each are equipped with non-slip rubber pads, which play the role of anti-skid and enhance the stability of the device. The bottom end of the base 15 between the legs 7 is equipped with a dust collection box 16, and the top of the dust collection box 16 is provided with activated carbon. The adsorption layer is convenient to remove the exhaust gas sucked by the dust collection pump 6 and avoid polluting the air. A dust collection pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com