Method for green recycling and regeneration of Fe2O3/TiO2 photocatalyst from waste SCR catalyst

A technology of SCR catalyst and photocatalyst, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalyst, etc., can solve the problems of narrow spectral response range, high raw material cost, low photocatalytic efficiency, etc., and achieve excellent Photocatalytic performance and the effect of improving leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

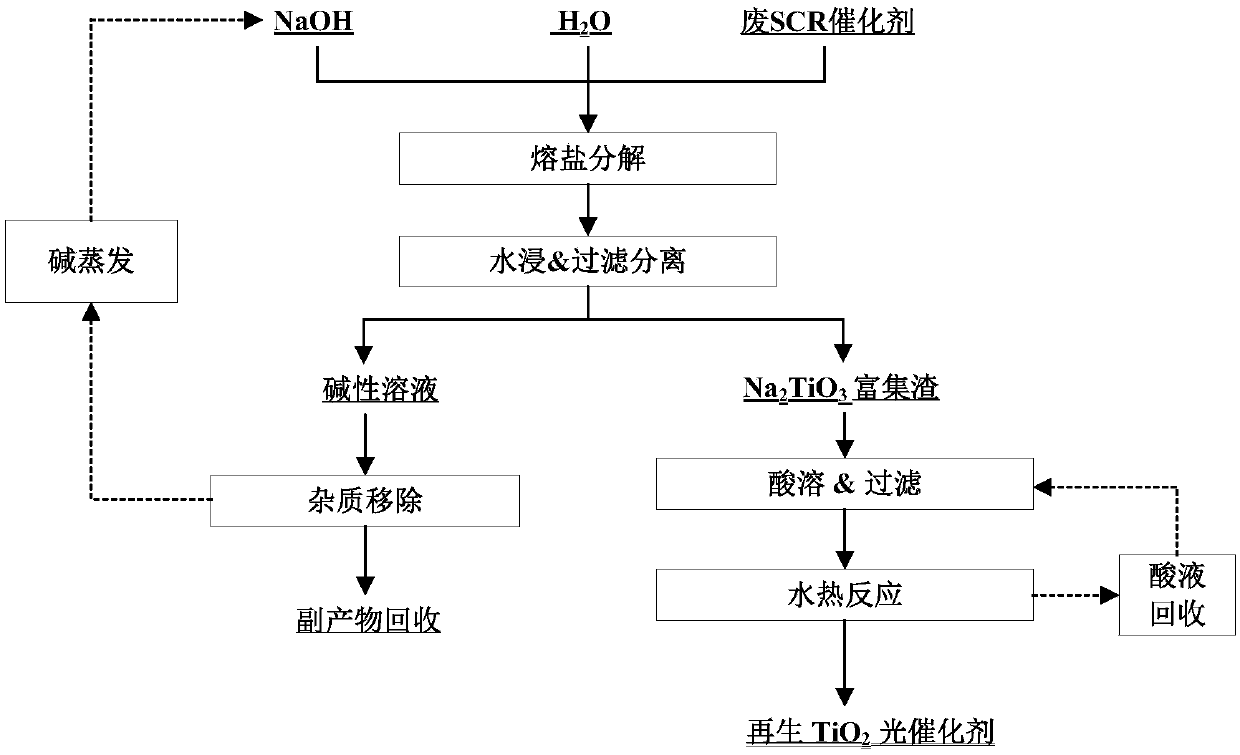

[0018] 1) Pretreatment: Ball milling of spent SCR catalyst to a particle size of 200 mesh;

[0019] 2)NaOH-H 2 O alkali fusion decomposition: the waste SCR catalyst obtained in step 1) is mixed and stirred evenly with NaOH solution, and the mass ratio of NaOH: waste SCR catalyst is 1.0; the resulting mixed slurry is put into a nickel crucible for high-temperature reaction treatment, and the reaction is completed After that, the alkali fusion reaction product is taken out. The reaction temperature was controlled to be 350°C, and the reaction time was controlled to be 5 minutes. The mass concentration of the NaOH solution is 60%; after alkali fusion decomposition treatment, the conversion efficiency of titanium is 80.5%;

[0020] 3) Water immersion treatment: add the alkali fusion reaction product obtained in step 2) into water and stir; the solid-to-liquid ratio is 10g / L, the stirring temperature is 55°C, and the stirring time is 1h; after the stirring is completed, filter to...

Embodiment 2

[0023] 1) Pretreatment: Ball milling of spent SCR catalyst to a particle size of 200 mesh;

[0024] 2)NaOH-H 2 O alkali fusion decomposition: the waste SCR catalyst obtained in step 1) is mixed and stirred evenly with NaOH solution, and the mass ratio of NaOH: waste SCR catalyst is 1.8:1; the resulting mixed slurry is put into a nickel crucible for high-temperature reaction treatment, and After the reaction was finished, the alkali fusion reaction product was taken out. The reaction temperature is controlled to be 450° C., and the reaction time is controlled to be 10 min. The mass concentration of the NaOH solution is 80%; after alkali fusion decomposition treatment, the conversion efficiency of titanium is 98.2%;

[0025]3) Water immersion treatment: Add the alkali fusion reaction product obtained in step 2) into water and stir; the solid-to-liquid ratio is 10g / L, the stirring temperature is 55°C, and the stirring time is 2h; after the stirring is completed, filter to obtai...

Embodiment 3

[0028] 1) Pretreatment: ball mill the spent SCR catalyst, with a particle size of 300 mesh;

[0029] 2)NaOH-H 2 O alkali fusion decomposition: the waste SCR catalyst obtained in step 1) is mixed and stirred evenly with NaOH solution, and the mass ratio of NaOH: waste SCR catalyst is 2.0:1; the resulting mixed slurry is put into a nickel crucible for high-temperature reaction treatment, and After the reaction was finished, the alkali fusion reaction product was taken out. The reaction temperature was controlled to be 550°C, and the reaction time was controlled to be 15 minutes. The mass concentration of the NaOH solution is 70%; after alkali fusion decomposition treatment, the conversion efficiency of titanium is 99.5%;

[0030] 3) Water immersion treatment: add the alkali fusion reaction product obtained in step 2) into water and stir; the solid-to-liquid ratio is 10g / L, the stirring temperature is 55°C, and the stirring time is 1.5h; after the stirring is completed, filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com