Non-soap-based facial cleanser and preparation method thereof

A technology of facial cleanser and soap base, applied in the field of daily chemicals, can solve the problems of unstable product, uneven application, easy to be sticky, etc., so as to improve the smearing feeling of the paste, easy to rinse off, and reduce the feeling of tightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

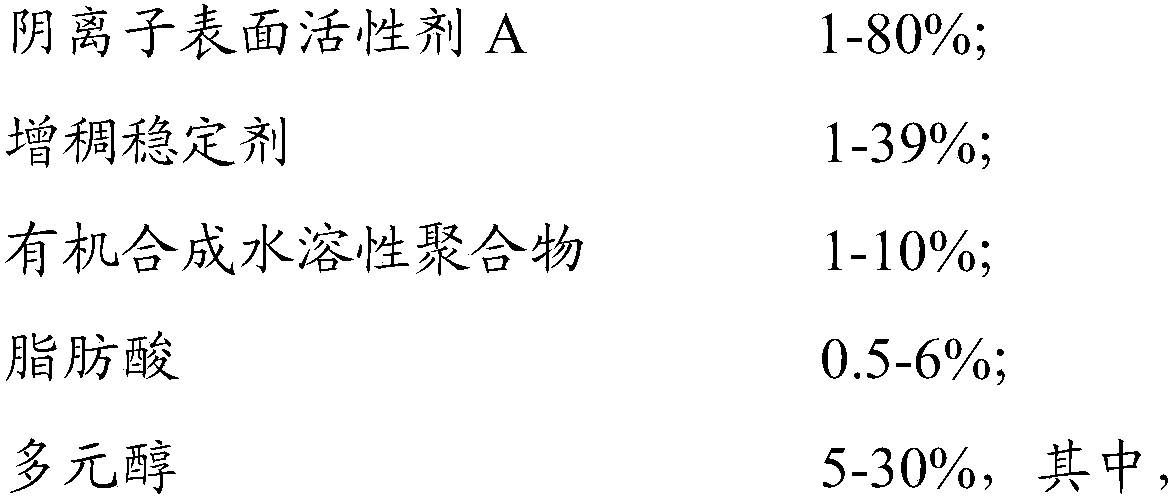

[0058] The present embodiment non-soap base facial cleanser, raw material comprises water and the component of following percentage by weight:

[0059] Anionic Surfactant A (25%):

[0060] Sodium Cocoyl Glycinate 13%,

[0061] Sodium Myristoyl Glutamate 2%,

[0062] Sodium Lauroyl Sarcosinate 10%;

[0063] Thickening Stabilizer (18%):

[0064] The mixture of mung bean starch and coconut oleic acid monoethanolamide sulfosuccinate disodium (mass percentage ratio is 50%: 50%) 18%;

[0065] Acrylic copolymer emulsion 8%;

[0066] Fatty acids (4%):

[0067] Lauric Acid 2%,

[0068] Myristic Acid 2%;

[0069] Polyols (10%):

[0070] Propylene Glycol 10%;

[0071] Methylisothiazolinone 0.1%.

[0072] The preparation method of non-soap-based facial cleanser described in embodiment 1 may further comprise the steps:

[0073] (1) Add anionic surfactant A, thickening stabilizer, fatty acid, polyol and water into the main reaction kettle, stir evenly, heat to 95°C to swell, keep...

Embodiment 2

[0077] The present embodiment non-soap base facial cleanser, raw material comprises water and the component of following percentage by weight:

[0078] Anionic Surfactant A (39%):

[0079] Sodium Cocoyl Glycinate 20%,

[0080] Sodium Methyl Lauroyl Taurate 9%,

[0081] Sodium Lauroyl Sarcosinate 10%;

[0082] Thickening Stabilizer (13%):

[0083] A mixture of corn starch and disodium lauryl sulfosuccinate (the mass percentage of corn starch and disodium lauryl sulfosuccinate is 80%:20%) 13%;

[0084] Acrylate copolymer emulsion 4%;

[0085] Fatty acids (4%):

[0086] Lauric Acid 2%,

[0087] Myristic Acid 2%;

[0088] Polyols (15%):

[0089] Glycerin 15%;

[0090] Methylisothiazolinone 0.1%.

[0091] The preparation method of non-soap-based facial cleanser described in embodiment 2, comprises the steps:

[0092] (1) Add anionic surfactant A, thickening stabilizer, fatty acid, polyol and water into the main reactor, stir evenly, heat to 90°C to swell, keep warm for 3...

Embodiment 3

[0096] The present embodiment non-soap base facial cleanser, raw material comprises water and the component of following percentage by weight:

[0097] Anionic Surfactant A (42%):

[0098] Potassium Lauryl Phosphate 42%,

[0099] Thickening Stabilizer (15%):

[0100] The mixture of potato starch and disodium lauryl sulfosuccinate (the mass percentage of potato starch and disodium lauryl sulfosuccinate is 75%: 25%) 15%;

[0101] Acrylic copolymer emulsion 6%;

[0102] Fatty acids (4%):

[0103] Stearic acid 2%,

[0104] Myristic Acid 2%;

[0105] Polyols (15%):

[0106] Glycerin 15%;

[0107] Methylisothiazolinone 0.1%.

[0108] The raw material of non-soap base facial cleanser of the present invention is as embodiment 3, and preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com