Preparation method of trench type device

A trench type and trench technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of lithography capacity limitation and limit the development of trench MOSFET devices, etc., to reduce the on-resistance, The effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

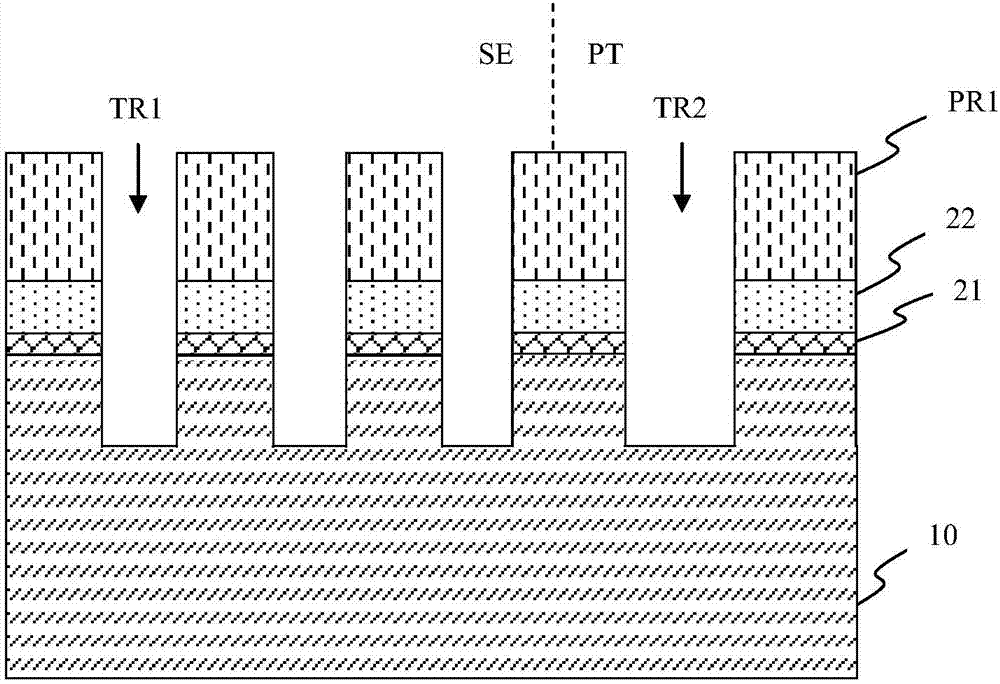

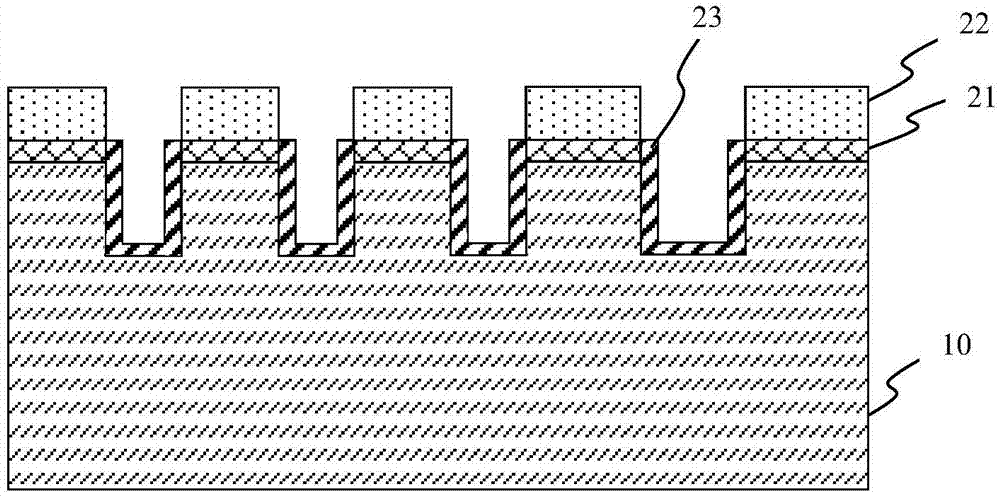

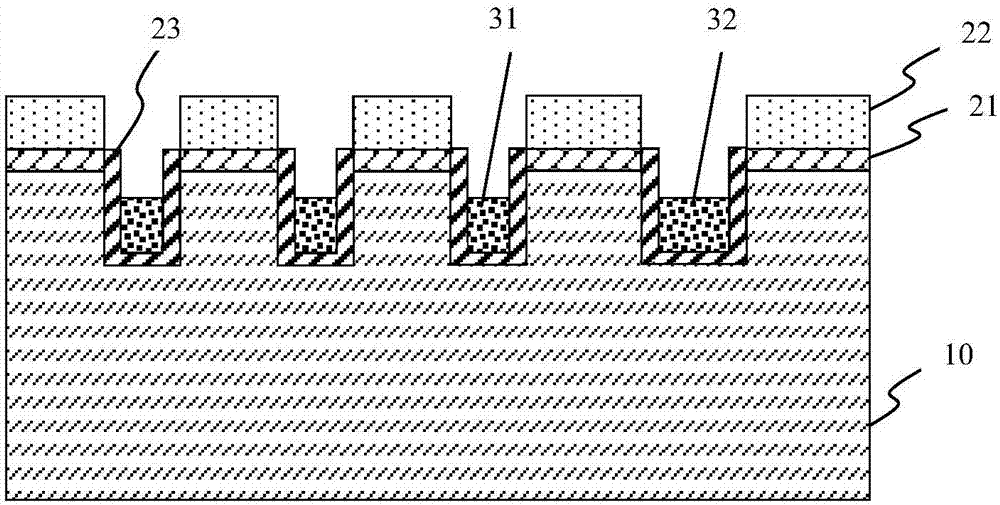

[0035] In a preferred embodiment, as Figure 1-9 As shown, a method for preparing a trench device is proposed, which may include:

[0036] Step S1, providing a substrate 10 including a cell region CE and a protection region PT, and sequentially depositing a first dielectric layer 21 and a second dielectric layer 22 on the upper surface of the substrate 10;

[0037] Step S2, etching the upper surface of the second dielectric layer 22 into the substrate 10 to form a plurality of first trenches TR1 in the cell region CE and at least one second trench TR2 in the protection region PT;

[0038] Step S3, covering the sidewalls and bottoms of the first trench TR1 and the second trench TR2 with a third dielectric layer 23;

[0039] Step S4, preparing the first conductive layer 31 in the first trench TR1 covering the third dielectric layer 23, and preparing the second conductive layer 32 in the second trench TR2 covering the third dielectric layer 23, and the first conductive The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com