Composite shock absorber with sacrificial structure

A shock absorber and shock pad technology, applied in the field of vibration damping structures, can solve the problems of inability to guarantee the survivability of high-precision MEMS devices, low overload resistance performance of high-precision MEMS devices, and achieve the effect of light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

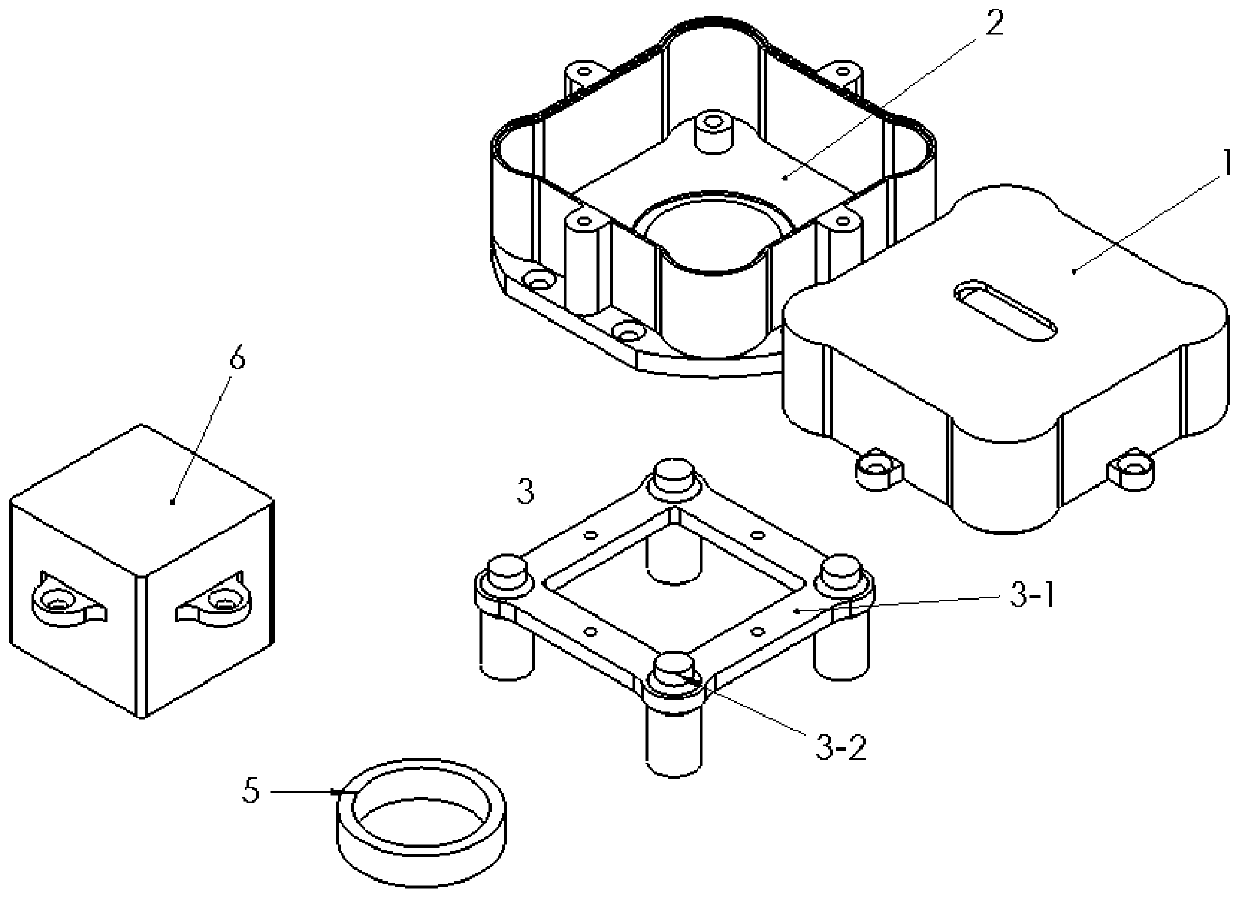

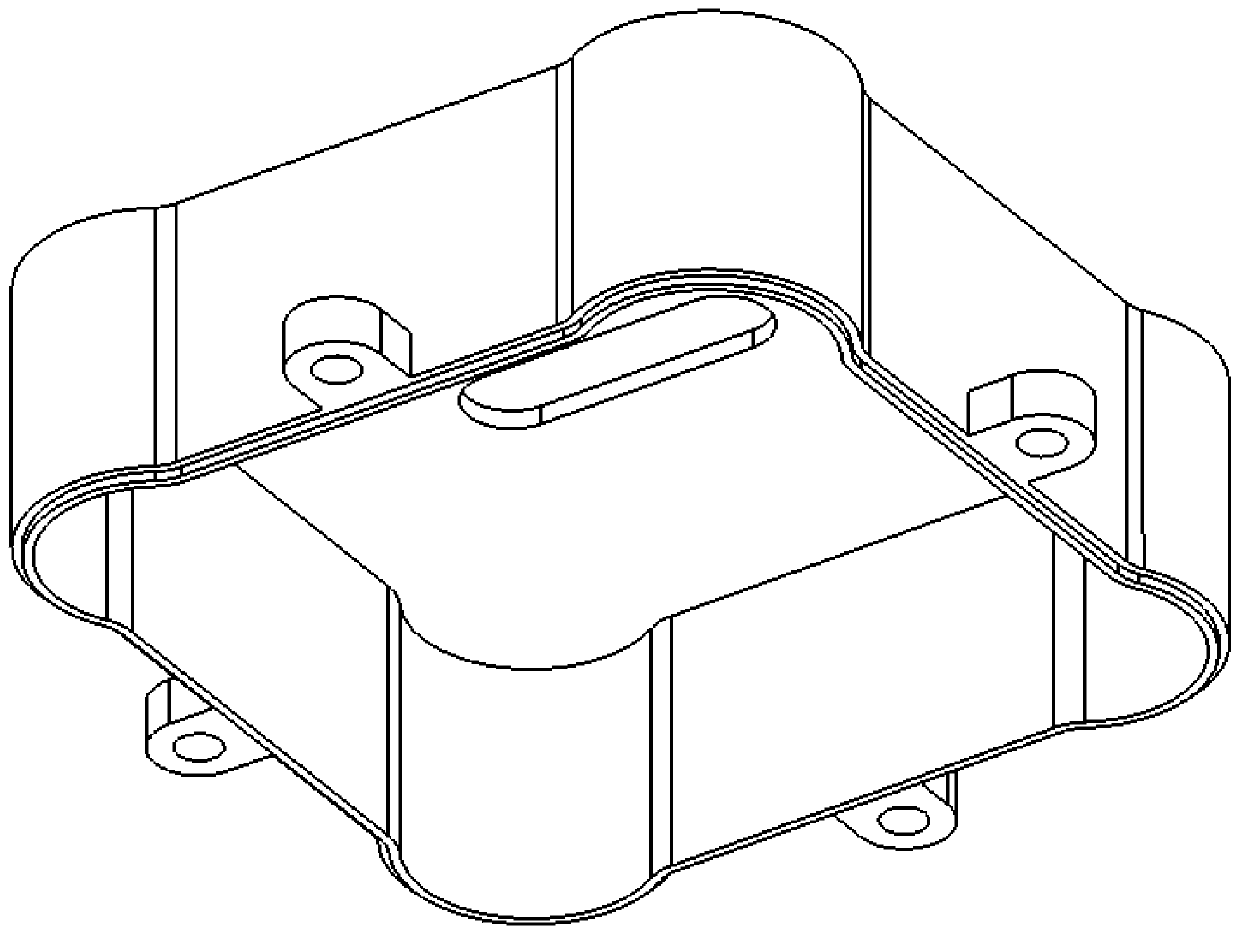

[0034] The present invention proposes a composite shock absorber with a sacrificial structure, which is composed of an upper shell 1, a lower shell 2, a shock-absorbing bracket 3, a shock-absorbing pad 4, and a sacrificial structure 5. The shock-absorbing pad 4 is directly formed by a mold. The shock-absorbing bracket 3 serves as a physical protection for the internal functional parts in the working environment, so that the entire assembly is integrated in transmission, transportation, and use. The invention has the characteristics of small size, easy assembly, light weight, high mechanical strength and high overload resistance.

[0035] It is generally believed that the overload of random vibration is less than 5000G, the frequency is 10Hz-2000Hz, and the approximate half-sine width is less than 1ms. The shock absorber 4 mainly isolates this kind of vibration, and it is necessary to ensure that the angular deviation of the shock absorber 3 is not greater than 0.05 during the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com