Assembling prestress orthogonal laminated wood shear wall

A technology of shear walls and glulam, applied to walls, building components, earthquake resistance, etc., can solve problems such as brittle failure, wall anti-lateral stiffness, strength degradation, and insufficient material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

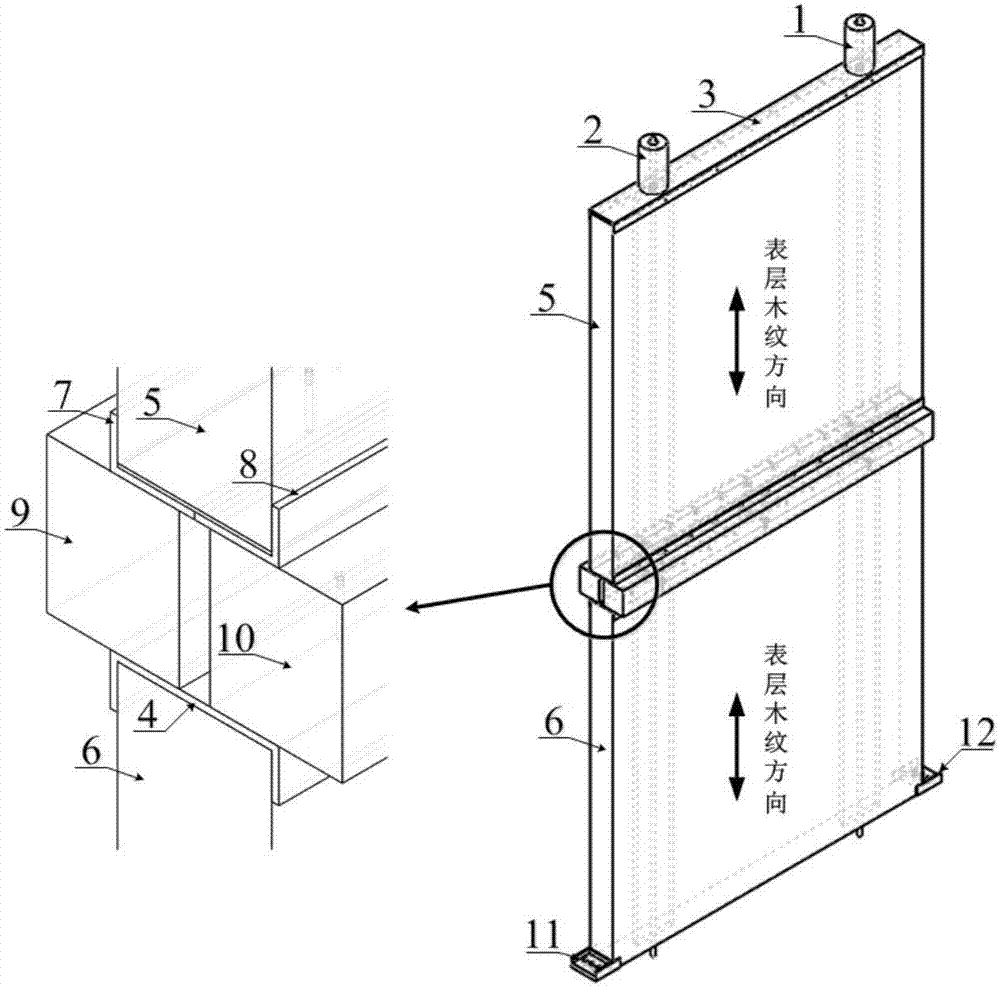

[0042] join Figure 14 The construction site fixes the first limiting steel component 11 and the second limiting steel component 12 on the foundation through embedded anchor bolts. The first bolt hole 1141, the second bolt hole 1142 and a third bolt hole 1143 reserved by the fourteenth steel plate 114 in the first limiting steel member 11 are used to pass through the embedded anchor bolts, and the second limiting The fourth bolt hole 1241 , the fifth bolt hole 1242 and the sixth bolt hole 1243 reserved by the fifteenth steel plate 124 in the steel member 12 are used to pass through the embedded anchor bolts.

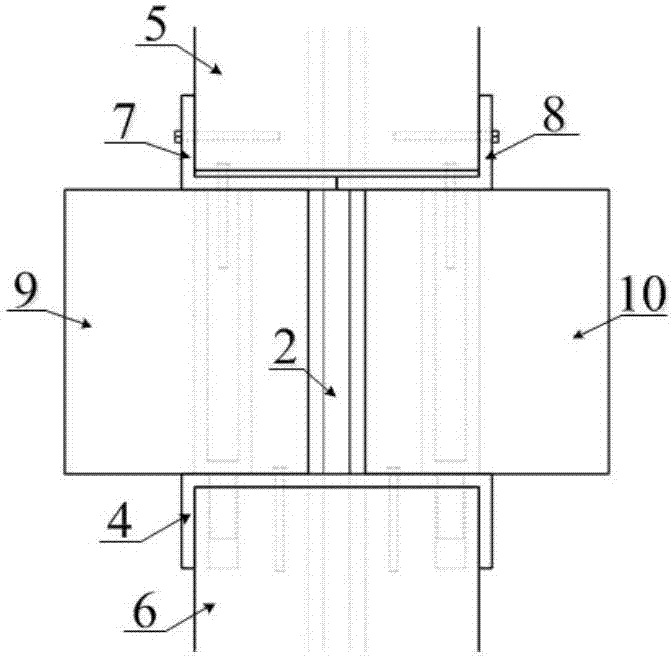

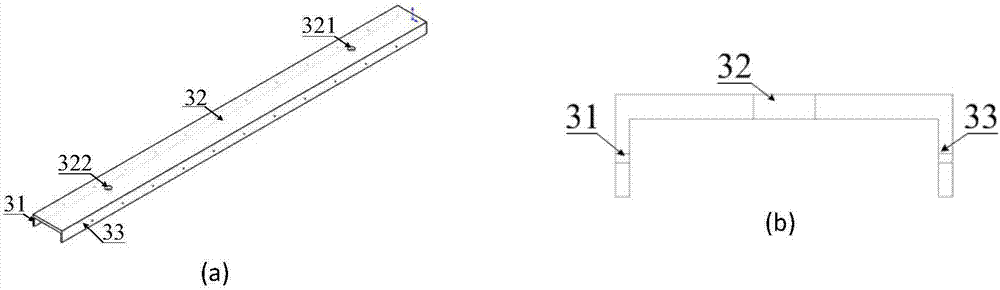

[0043] see Figure 12 and Figure 13 The factory fixes the lower floor beam 4 to the top of the lower floor CLT wallboard 6 by screws; screw holes are reserved on the sixth steel plate 43 of the lower floor beam 4 for screwing in screws.

[0044] see Figure 13 and Figure 14 , a temporary support is erected on the construction site, and the lower CLT wall panel 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com