Preparation method of tungsten selenide thin film

A technology of tungsten selenide and thin film, which is applied in the direction of electrolytic inorganic material coating, etc., can solve the problems that the uniformity of thin film products is difficult to control, and the shape of prepared products is difficult to control, so as to achieve strong controllability of film shape and thickness, and realize thin film Shape and thickness, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

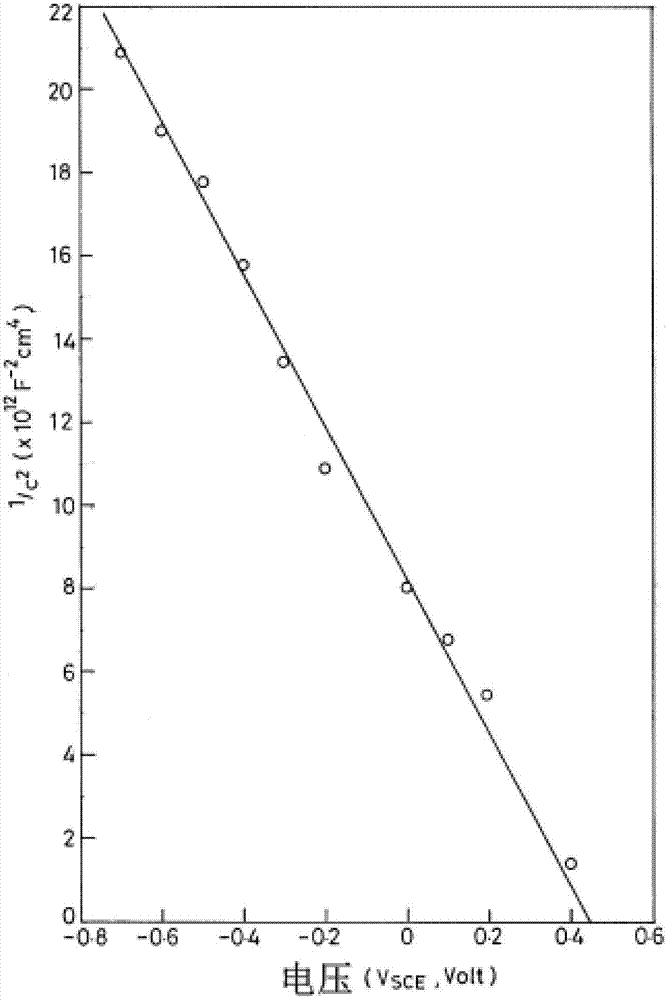

Image

Examples

Embodiment 1

[0025] A preparation method of the tungsten selenide thin film of the present invention specifically comprises the following steps:

[0026] (1) Clean the fluorine-doped tin dioxide conductive glass (FTO, used as the cathode sheet) three times with detergent, soak it in isopropanol ultrasonically for 15 minutes, then soak it in ethanol ultrasonically for 15 minutes, rinse it three times with deionized water, and then Drying with nitrogen gas to obtain fluorine-doped tin dioxide conductive glass with a clean surface;

[0027] (2) Configure a mixed solution containing 1mol / L sodium chloride, 2mmol / L selenous acid, 1mmol / L sodium tungstate solution, 0.5mol / L citric acid and 0.5mol / L disodium edetate, and use The pH of the mixed solution was adjusted to be 1 with hydrochloric acid, and then the mixed solution was deoxygenated by nitrogen bubbling for 15 minutes;

[0028] (3) With the mixed solution obtained in step (2) as the electrochemical deposition solution, with the clean fl...

Embodiment 2

[0032] A preparation method of the tungsten selenide thin film of the present invention specifically comprises the following steps:

[0033] (1) Clean the fluorine-doped tin dioxide conductive glass (FTO, used as the cathode sheet) three times with detergent, soak it in isopropanol ultrasonically for 15 minutes, then soak it in ethanol ultrasonically for 15 minutes, rinse it three times with deionized water, and then Drying with nitrogen gas to obtain fluorine-doped tin dioxide conductive glass with a clean surface;

[0034] (2) Configure a mixed solution containing 1mol / L sodium chloride, 2mmol / L selenous acid, 1mmol / L sodium tungstate solution, 0.5mol / L citric acid and 0.5mol / L disodium edetate, and use The pH of the mixed solution was adjusted to be 1 with hydrochloric acid, and then the mixed solution was deoxygenated by nitrogen bubbling for 15 minutes;

[0035] (3) With the mixed solution obtained in step (2) as the electrochemical deposition solution, with the clean fl...

Embodiment 3

[0039] A preparation method of the tungsten selenide thin film of the present invention specifically comprises the following steps:

[0040] (1) Clean the fluorine-doped tin dioxide conductive glass (FTO, used as the cathode sheet) three times with detergent, soak it in isopropanol ultrasonically for 15 minutes, then soak it in ethanol ultrasonically for 15 minutes, rinse it three times with deionized water, and then Drying with nitrogen gas to obtain fluorine-doped tin dioxide conductive glass with a clean surface;

[0041](2) Configure a mixed solution containing 1mol / L sodium chloride, 2mmol / L selenous acid, 1mmol / L sodium tungstate solution, 0.5mol / L citric acid and 0.5mol / L disodium edetate, and use The pH of the mixed solution was adjusted to be 1 with hydrochloric acid, and then the mixed solution was deoxygenated by nitrogen bubbling for 15 minutes;

[0042] (3) With the mixed solution obtained in step (2) as the electrochemical deposition solution, with the clean flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com