Stainless steel impeller for phosphoric acid slurry pump and its preparation method

A technology of stainless steel and slurry, applied in the field of stainless steel impeller for phosphoric acid slurry pump and its preparation, can solve the problems of difficult casting production, large difference in wall thickness, brittle phase casting cracks, etc., and achieve good shape, toughness, good strength , to avoid the effect of casting cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

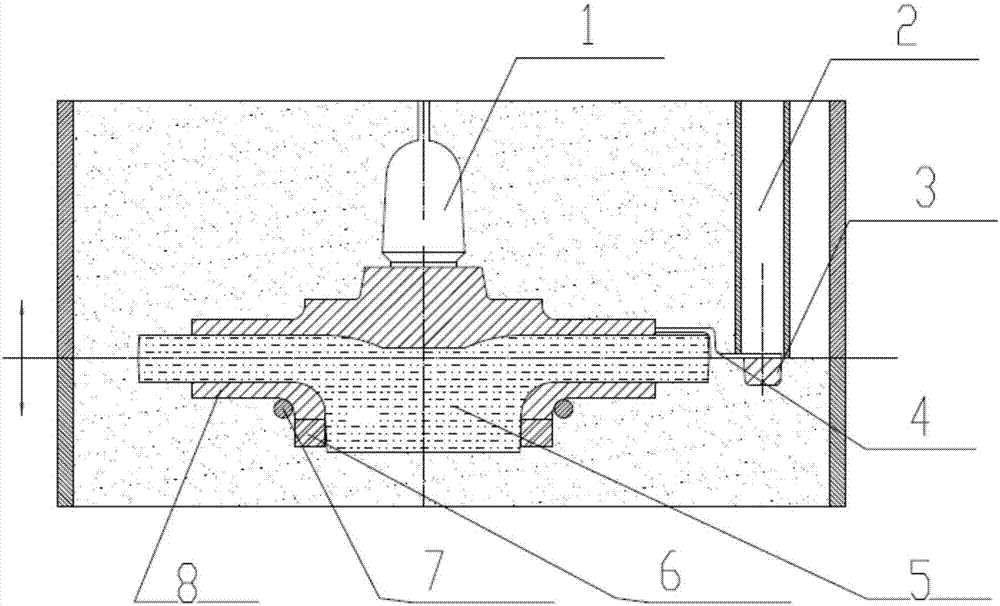

[0032] The invention provides a stainless steel impeller for a phosphoric acid slurry pump and a preparation method thereof. The raw materials are high-carbon ferrochrome 15-18%, 30Cr13 5-6%, CD4MCuN 28-32%, 1.4460K 18-25%, and furnace charge 20% ~30%, ferromolybdenum 12~15%, nickel plate 1.0~1.5%, rare earth silicon magnesium 0.8~1.0%, copper plate 8~12%, ferrosilicon 0.5~1.0%, ferromanganese 0.8~1.0%, ferrotitanium and / or 0.5-0.8% ferroniobium, 0.15-0.20% ferrovanadium, 2.5-3.5% ferrochromium nitride.

[0033] The preparation method comprises the following steps:

[0034] Step 1: Remove sand and rust from 30Cr13, CD4MCuN and 1.4460K;

[0035] Step 2: Add recycled charge, nickel plate, red copper plate, ferromolybdenum, and high-carbon ferrochrome to the intermediate frequency furnace, bake with the furnace at a temperature of 1430-1470°C until it is melted, and then remove slag;

[0036] Step 3: Add ferrosilicon and ferromanganese, and make slag and deoxidize when the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com