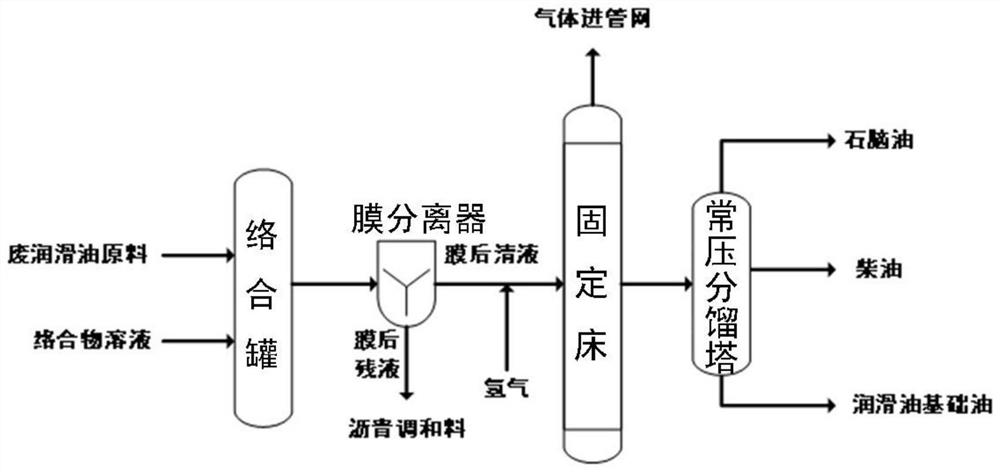

A regeneration treatment method of complexation-membrane separation-hydrogenation-fractionation of waste lubricating oil

A waste lubricating oil and membrane separation technology, which is applied in the fields of hydrotreating process, lubricating composition, and hydrocarbon oil treatment, can solve the problems of easy deposition, poor product properties, and easy coking, etc., and achieve high added value and good product properties , the effect of easing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to the above process, combined with specific waste lubricating oil, the reaction is carried out, and the specific conditions are as follows: the complexing agent is triethanolamine, the concentration of its aqueous solution is 20w%, the mixing mass ratio of waste lubricating oil and solution is 40:1, and the stirring temperature is 120°C , 60min when stirring and mixing; membrane separation pump flow rate is 5m 3 / h, temperature is 70°C, pressure is 0.1MPa; hydrofining reaction temperature is 350°C, reaction pressure is 8.0MPa, hydrogen-oil ratio is 1000:1, feed volume space velocity is 0.5h -1 , Ni in the catalyst is 3.5w%, Mo is 15.0w%, and W is 2.0w%.

Embodiment 2

[0031] According to above-mentioned technology, in conjunction with concrete waste lubricating oil, carry out reaction, specific condition is as follows: complexing agent is sodium tripolyphosphate, and its aqueous solution concentration is 10w%, waste lubricating oil and solution mixing mass ratio are 10:1, stirring temperature is 180°C, stirring and mixing for 20 minutes; the flow rate of the membrane separation pump is 10m 3 / h, temperature 130°C, pressure 0.3MPa; hydrofining reaction temperature 340°C, reaction pressure 6.0MPa, hydrogen-oil ratio 1000:1, feed volume space velocity 1.0h -1 , Ni in the catalyst is 4.0w%, Mo is 14.0w%, and W is 3.0w%.

Embodiment 3

[0033]According to the above process, combined with specific waste lubricating oil, the reaction is carried out, and the specific conditions are as follows: the complexing agent is ethylenediamine tetraacetate, the concentration of its aqueous solution is 30w%, and the mixed mass ratio of waste lubricating oil and solution is 50:1, The stirring temperature is 60°C, and the mixing time is 90 minutes; the flow rate of the membrane separation pump is 2m 3 / h, temperature is 40°C, pressure is 0.5MPa; hydrofining reaction temperature is 390°C, reaction pressure is 12.0MPa, hydrogen-oil ratio is 1000:1, feed volume space velocity is 1.5h -1 , Ni in the catalyst is 2.0w%, Mo is 16.0w%, and W is 1.5w%.

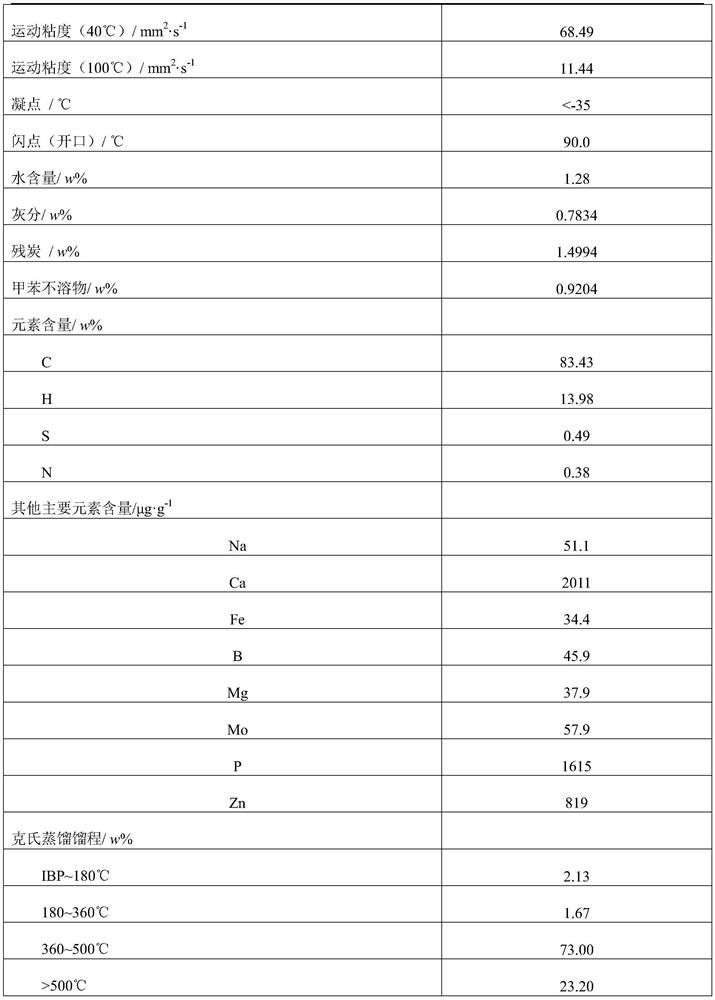

[0034] (1) Raw material properties of waste lubricating oil

[0035]

[0036]

[0037] (2) Material balance after treatment

[0038]

[0039] (3) Main product properties

[0040] Naphtha (IBP~180℃) Properties and Composition

[0041]

[0042] Properties and Composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com