Anti-blocking adjustable thermosetting powder coating spraying device

A thermosetting powder and spraying device technology, applied in spraying devices, liquid spraying devices, etc., can solve problems that affect the spraying function, internal residue, pipe blockage, etc., achieve good spraying effect, increase initial speed, and ensure product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

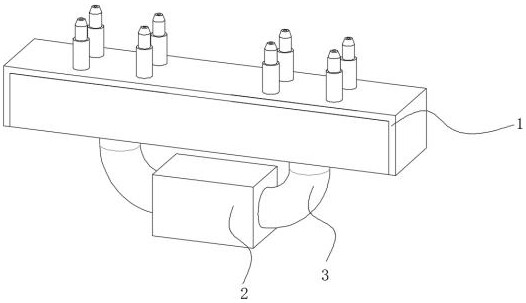

[0030] see Figure 1-Figure 4 , the present invention provides a technical solution: an anti-clogging adjustable thermosetting powder coating spraying device, comprising a spray box 1, the lower surface of the spray box 1 is symmetrically provided with a gas transmission metal pipe 3, and the bottom end of the gas transmission metal pipe 3 is arranged A gas conveyor 2 is fixedly connected.

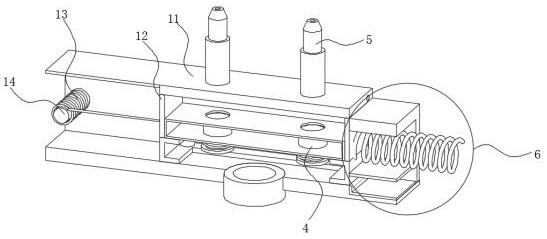

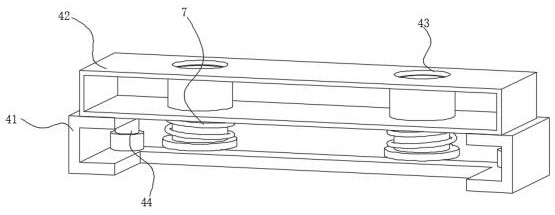

[0031] The spray box 1 includes an outer box shell 11, the upper part of the inner wall of the outer box shell 11 is evenly provided with a modified nozzle 5, the middle part of the inner wall of the outer box shell 11 is provided with a recovery device 6, and the left and right sides of the recovery device 6 are symmetrically provided with inner sliding boxes 12. The inner wall of the inner sliding box 12 is provided with a material spraying device 4, the side of the outer surface of the inner sliding box 12 away from the recovery device 6 is fixedly connected with a traction rope 13, and...

Embodiment 2

[0042] see Figure 1-Figure 5 , the present invention provides a technical solution: on the basis of the first embodiment, an anti-clogging adjustable thermosetting powder coating spraying device includes a spray box 1, and the lower surface of the spray box 1 is symmetrically provided with a gas transmission metal pipe 3, The gas transmission machine 2 is fixedly connected to the bottom end of the gas transmission metal pipe 3 .

[0043] The spray box 1 includes an outer box shell 11, the upper part of the inner wall of the outer box shell 11 is evenly provided with a modified nozzle 5, the middle part of the inner wall of the outer box shell 11 is provided with a recovery device 6, and the left and right sides of the recovery device 6 are symmetrically provided with inner sliding boxes 12. The inner wall of the inner sliding box 12 is provided with a material spraying device 4, the side of the outer surface of the inner sliding box 12 away from the recovery device 6 is fixed...

Embodiment 3

[0053] see Figure 1-Figure 6 , the present invention provides a technical solution: on the basis of the first embodiment, an anti-clogging adjustable thermosetting powder coating spraying device includes a spray box 1, and the lower surface of the spray box 1 is symmetrically provided with a gas transmission metal pipe 3, The gas transmission machine 2 is fixedly connected to the bottom end of the gas transmission metal pipe 3 .

[0054]The spray box 1 includes an outer box shell 11, the upper part of the inner wall of the outer box shell 11 is evenly provided with a modified nozzle 5, the middle part of the inner wall of the outer box shell 11 is provided with a recovery device 6, and the left and right sides of the recovery device 6 are symmetrically provided with inner sliding boxes 12. The inner wall of the inner sliding box 12 is provided with a material spraying device 4, the side of the outer surface of the inner sliding box 12 away from the recovery device 6 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com