Preparation method of high-performance modified starch

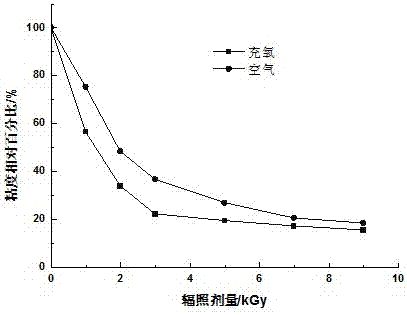

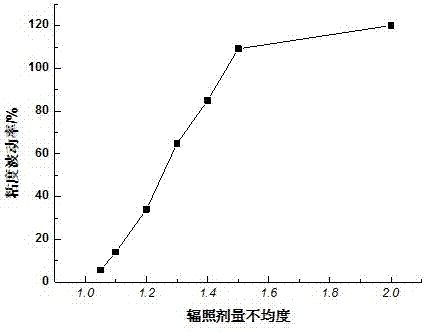

A modified starch and high-performance technology, applied in the field of modified starch, can solve the problems of high irradiation cost, unstable product quality, and large dispersion of radiation-modified viscosity, so as to save energy, reduce the total irradiation time, and The effect of time t reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take cornstarch with a moisture content of 12.3% and carry out microwave drying treatment, and stir at least 20 times at the same time, and the moisture content of each part is 8%; the dried starch is packed in a shaped sealed bag, each bag length × width × thickness = 40cm ×30cm×8cm, pre-place 2 dosimeters on the outside of the packaging bag; the predetermined absorbed dose of the product is 1kGy, and the total irradiation time is 3.125 hours; the above-mentioned starch bag is placed in a special irradiation box, and γ-rays are used for frontal irradiation Irradiation treatment with a dose rate of 0.2kGy / hour and an irradiation time of 2.5 hours; then the above-mentioned irradiated starch in a sealed bag was oxygenated, and the oxygen partial pressure was added to 0.1MPa; shaping to keep its cuboid surface flat; The aforesaid oxygenated and shaped sealed packaging bags were irradiated on the reverse side with the orientation and direction reversed, with a dose rate of 0...

Embodiment 2

[0057] Take cornstarch with a moisture content of 12.3% and carry out infrared drying treatment, and stir at least 20 times at the same time, and the moisture content of each part is 6.7%; the dried starch is packed in a shaped sealed bag, each bag length × width × thickness = 38cm ×28cm×7.5cm, 2 dosimeters are pre-placed on the outside of the packaging bag; the predetermined absorbed dose of the product is 3kGy; the above-mentioned starch bag is placed in a special irradiation box, and X-rays are used for frontal irradiation treatment, with a dose rate of 0.75 kGy / hour, irradiation time 2 hours; then carry out oxygenation to the above-mentioned irradiated starch in sealed bag, supplement oxygen partial pressure to 0.1MPa; Seal the packaging bag, reverse the direction and orientation, and perform reverse side irradiation treatment with a dose rate of 3 kGy / hour and an irradiation time of 0.5 hour. The total irradiation time was 2.5 hours. The modified starch after irradiation...

Embodiment 3

[0060] Take cornstarch with a moisture content of 12.3% to dry in the sun, and stir it no less than 20 times at the same time, and the moisture content of each part is 8.0%; the dried starch is packed in a shaped sealed bag, and the length of each bag × width × thickness = 40cm×30cm×5cm, place at least 3 dosimeters on the outside of the packaging bag in advance; the predetermined absorbed dose of the product is 6kGy; the above-mentioned starch bag is placed in a special irradiation box, and the front side is irradiated with electron beams, and the delivery time is 10 minutes; then carry out oxygenation to the above-mentioned irradiated starch in sealed bags, supplement oxygen partial pressure to 0.1MPa; , carry out the irradiation treatment on the reverse side, and the delivery time is 2.5 minutes. The modified starch after irradiation treatment is taken out and stored in the warehouse, protected from moisture.

[0061] Measurement results: the minimum product absorbed dose o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com