Mineral casting material filled with ceramic waste, application thereof and products

A technology of ceramic waste and mineral castings, which is applied in the field of mineral casting materials, can solve the problems of raw material supply and price rise, and achieve the effects of improving equipment precision and surface steel wear resistance, reducing costs, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

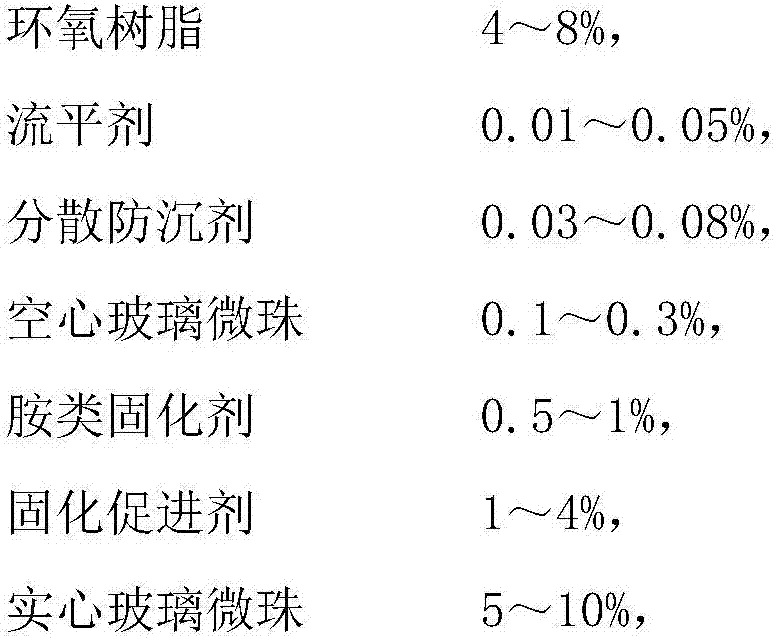

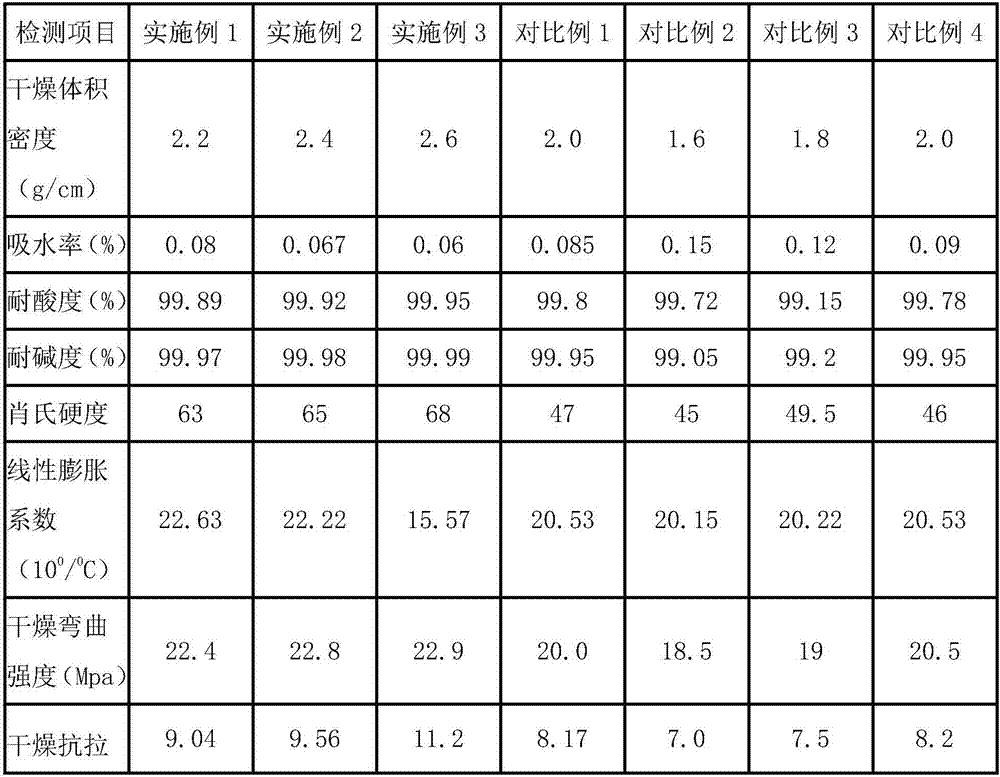

[0039] The present embodiment provides a mineral casting material filled with ceramic waste, comprising the following components by weight percentage: 8% epoxy resin, 0.03% leveling agent, 0.08% dispersion anti-sedimentation agent, 0.3% hollow glass microspheres, Amine curing agent 0.55%, curing accelerator 3%, 100-200 mesh solid glass beads 6%, 800-1500 mesh silica powder 6%, ceramic waste 75%, additives 1.04%;

[0040] The ceramic waste mentioned above is ceramic particles obtained through pulverization and ball milling, with a diameter of ≤30 mm. The ceramic waste in this embodiment is preferably composed of ceramic particles with different diameters, which are respectively primary ceramic particles and secondary ceramic particles, one of which is The diameter of the first-grade ceramic particles is 2-5mm, and the weight percentage is 45%, the diameter of the second-grade ceramic particles is 10-30mm, and the weight percentage is 30%; the additives are 0.4% of defoamer, 0.04...

Embodiment 2

[0051] This embodiment is basically the same as Example 1, except that the weight percentages of each component are different, as follows: 4% epoxy resin, 0.01% leveling agent, 0.038% dispersing and anti-settling agent, and 0.1% hollow glass microspheres. %, amine curing agent 0.81%, curing accelerator 4%, 100-200 mesh solid glass beads 8%, 800-1500 mesh silicon powder 7%, the diameter of the primary ceramic particles is 2-5mm, and the weight percentage is 30 %, the diameter of secondary ceramic particles is 10-30mm, the percentage by weight is 45%, the defoamer is 0.3%, the toner is 0.05% and the diluent is 0.7%.

[0052] Wherein, in this embodiment, the amine curing agent specifically adopts aromatic amine, and the curing accelerator specifically adopts aminoethylpirazine.

Embodiment 3

[0054] This example is basically the same as Example 1, except that the weight percentages of each component are different, specifically as follows: 6% epoxy resin, 0.05% leveling agent, 0.05% dispersing anti-settling agent, and 0.2% hollow glass microspheres. %, amine curing agent 0.67%, curing accelerator 2%, 100-200 mesh solid glass beads 5%, 800-1500 mesh silicon powder 5%, the diameter of the primary ceramic particles is 2-5mm, and the weight percentage is 40 %, the diameter of the secondary ceramic particles is 10-30mm, the weight percentage is 40%, the defoamer is 0.1%, the toner is 0.03% and the diluent is 0.9%.

[0055] Wherein, in this embodiment, the amine curing agent specifically adopts aliphatic amine, and the curing accelerator specifically adopts aminoethylpirazine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com